Measuring method for optical interval of refraction and reflection system with hollow main lens

A technology of optical interval and measurement method, which is applied in the direction of testing optical performance, measuring device, geometric characteristics/aberration measurement, etc. It can solve the problems that the optical interval between primary and secondary mirrors cannot be directly and accurately measured, and achieve the effect of improving the accuracy of assembly and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Describe the present invention below in conjunction with specific embodiment:

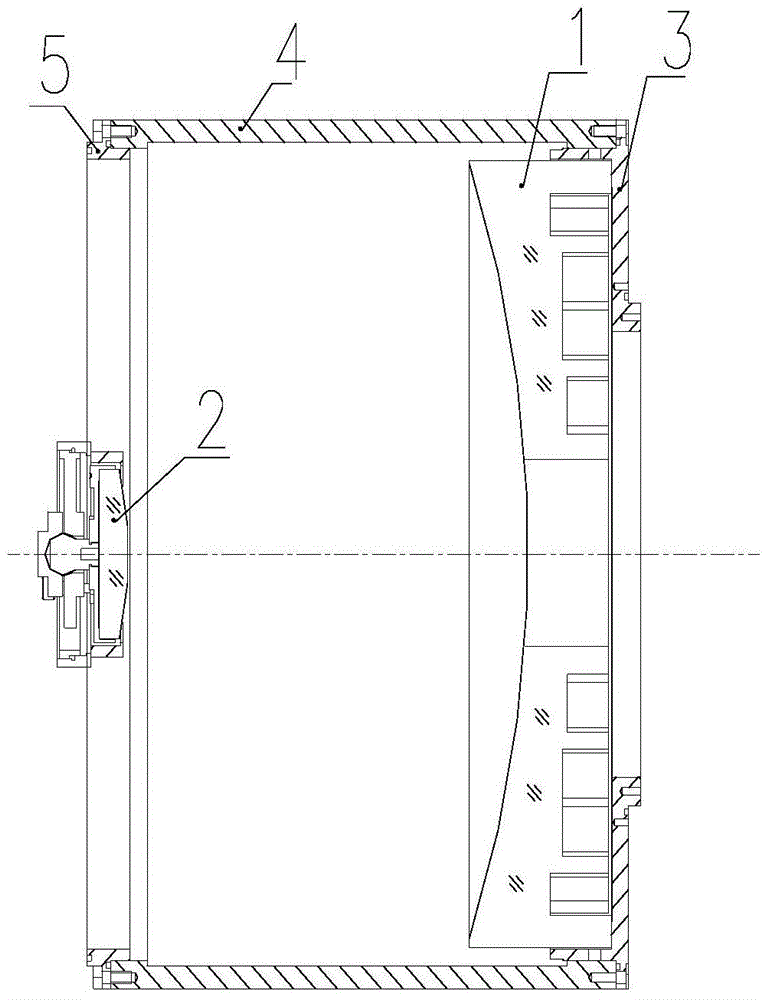

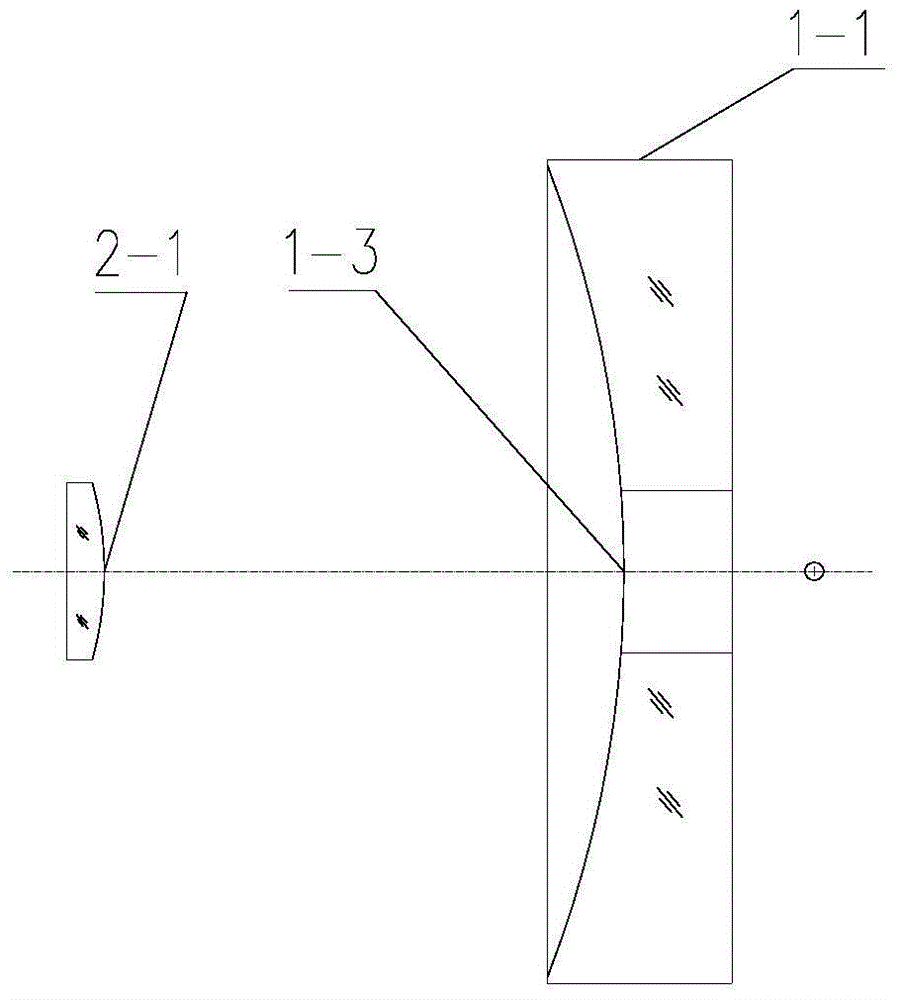

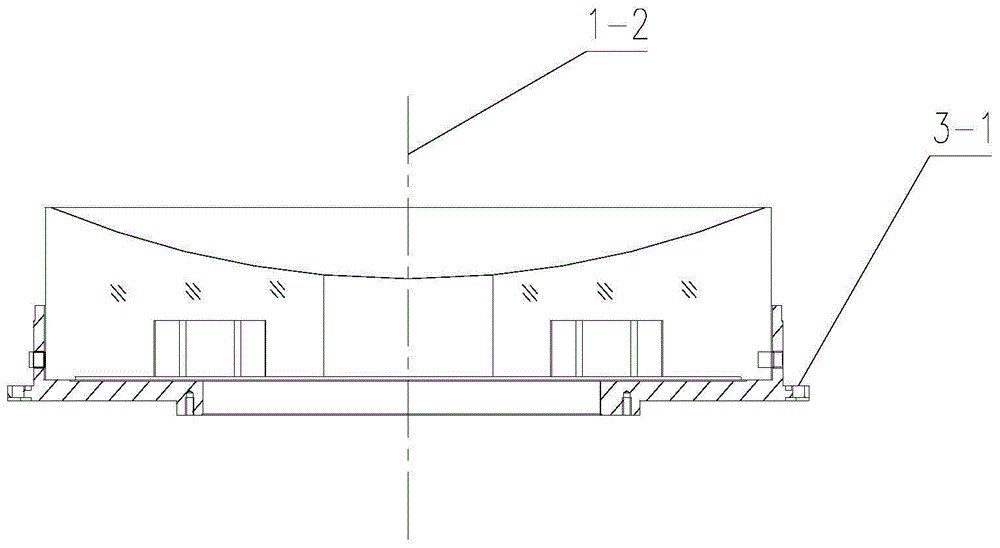

[0032] The present invention mainly aims at the technical problem that the optical distance between the primary and secondary mirrors cannot be directly and accurately measured due to the hollow primary mirror in the optical-mechanical adjustment of the existing catadioptric optical system, and proposes a method for the optical distance of the catadioptric system containing the hollow primary mirror. The measurement method is to use a coordinate measuring instrument such as a three-coordinate measuring instrument to measure the outer circle of the primary mirror to determine the center position of the primary mirror, and then use a three-coordinate measuring instrument to collect points on the surface of the primary mirror once and determine the location of the point and the apex of the primary mirror. The z-direction dimension of the position, combined with the z-direction dimension of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com