Steel rail milling and grinding vehicle grinding wheel unbalance amount adjusting hole filling glue and using method thereof

A technology for rail milling and grinding vehicles and balancing weights, which is applied in the direction of grinding devices, grinding machine parts, grinding/polishing equipment, etc., and can solve the problems of easily broken grinding wheels, small weight loss range, and large outer diameter of grinding wheels. Achieve the effect of solving the problem of static balance adjustment and overcoming the problem of easy falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0026] The performance test of three different hole-filling glue resin ratio schemes is now carried out. The three different hole-filling glue resin ratio schemes are shown in Table 1. The ratio of resin, curing agent, and catalyst remains unchanged. The mechanical properties of hole-filling glue with different proportions are shown in Table 2, and the performance test results of hole-filling glue with different proportions are shown in Table 3.

[0027] Table 1 Resin ratio of different schemes

[0028] Proportion (%) Novolac resin liquid epoxy resin solid epoxy resin Option One 12.6 11.5 75.9 Option II 15.1 11.7 73.2 third solution 20.0 12.1 67.9

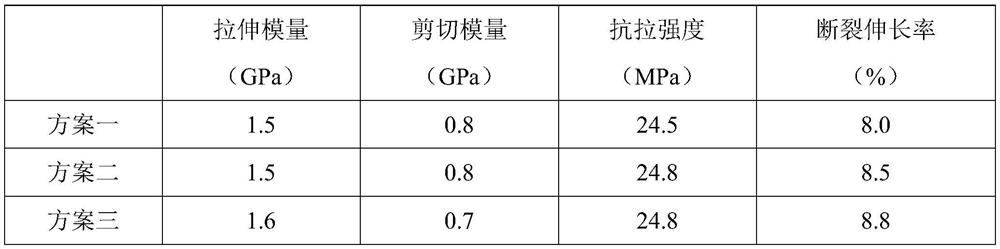

[0029] Table 2 Mechanical properties of hole-filling glue with different proportions

[0030]

[0031] Table 3 Performance test results of different proportions of hole-filling glue

[0032] Curing time (h) Fluidity (mm) Curing temperature (°C) Bond strength (MPa) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com