A hole-filling glue for adjusting the unbalance amount of the grinding wheel of rail milling and grinding vehicles and its application method

A technology for rail milling and grinding vehicles and balance weights, which is applied in the direction of grinding devices, grinding/polishing equipment, and parts of grinding machine tools, and can solve the problems of easily broken grinding wheels, small weight loss range, and heavy quality, and achieve a solution Static balance adjustment problem, overcome the effect of easy falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0026] The performance of three different pore-filling resin proportioning schemes are now tested. The three different pore-filling glue resin proportioning schemes are shown in Table 1. The proportions of resin, curing agent and catalyst remain unchanged. The mechanical properties of different proportions of pore-filling glue are shown in Table 2, and the performance test results of different proportions of pore-filling glue are shown in Table 3.

[0027] Table 1 The ratio of different resin schemes

[0028] Proportion (%) Novolac resin liquid epoxy resin solid epoxy resin Option One 12.6 11.5 75.9 Option II 15.1 11.7 73.2 third solution 20.0 12.1 67.9

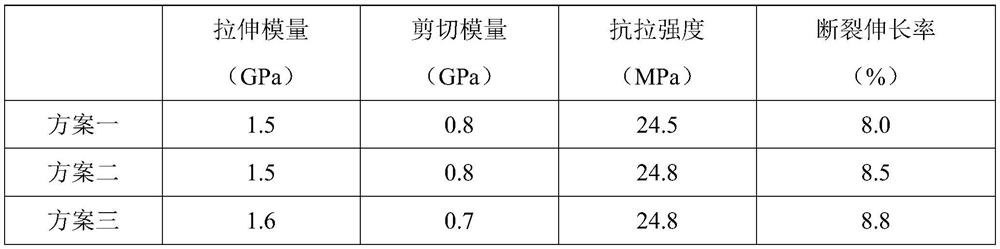

[0029] Table 2 Mechanical properties of different proportions of filling glue

[0030]

[0031] Table 3 The performance test results of different proportions of filling glue

[0032] Curing time (h) Fluidity(mm) Curing temperature(℃) Bonding strength (MPa) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com