A Flush Membrane Piezoresistive Ceramic Pressure Sensor

A pressure sensor and piezoresistive technology, applied in the field of flush-membrane piezoresistive ceramic pressure sensors, can solve the problems of fragility of alumina ceramics, and achieve the effect of improving mechanical strength, good stability and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

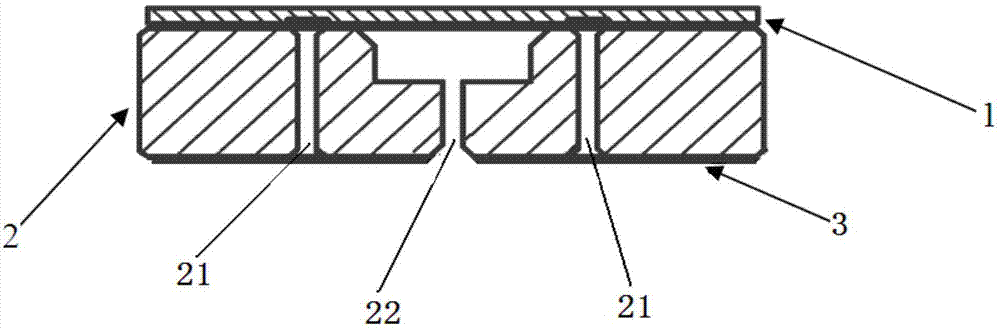

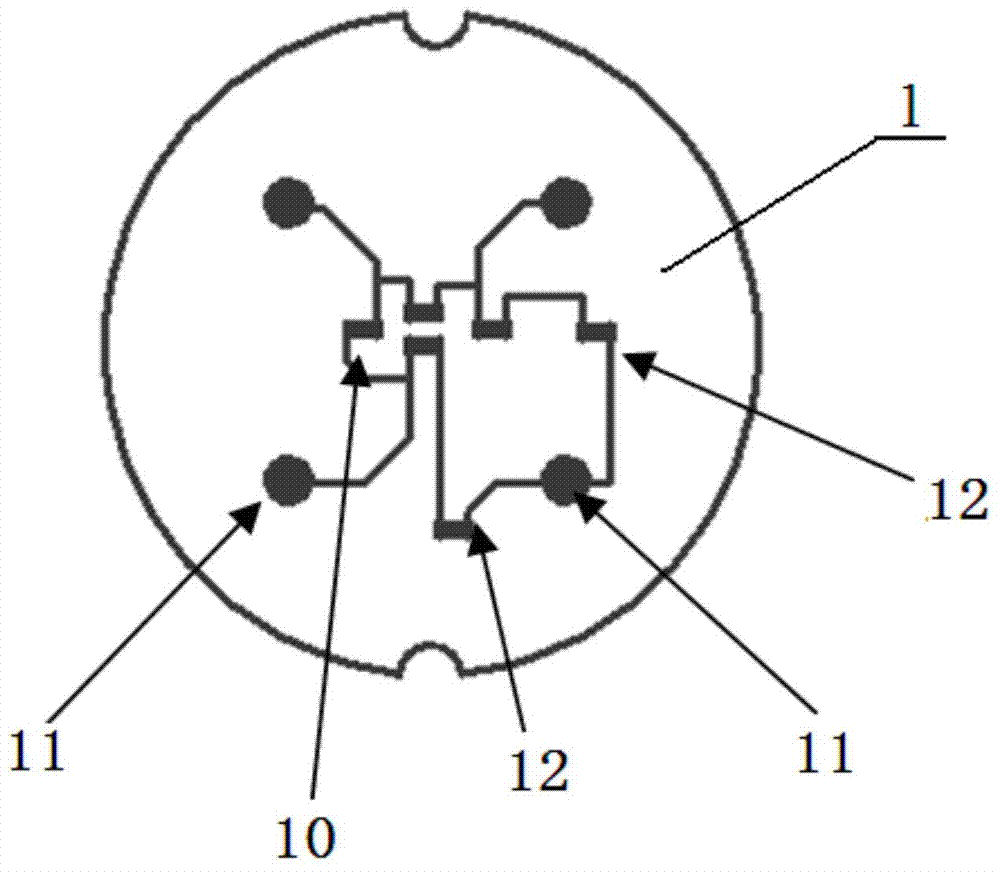

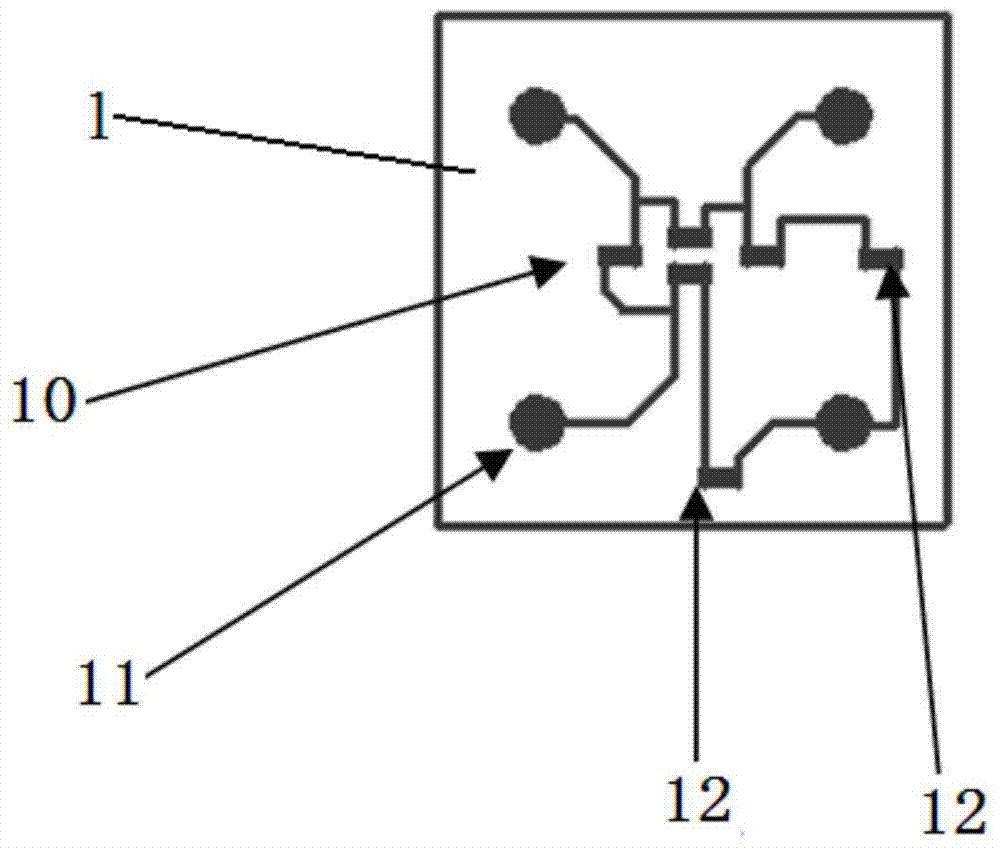

[0021] Figure 1 to Figure 3b As shown, it involves a flush membrane piezoresistive ceramic pressure sensor, including a ceramic ring 2, a ceramic elastic diaphragm 1 printed and sintered on the top of the ceramic ring 2 through glass glaze paste, and a ceramic elastic diaphragm 1 printed and sintered on the upper part of the ceramic ring 2 through conductive paste. The signal conditioning circuit 3 at the bottom of the ceramic ring 2; wherein, the ceramic elastic diaphragm 1 is evenly provided with four pads 11 connected to the four ceramic ring through holes 21 on the ceramic ring 2, and connected to the pads 11 There are four bridge resistors 10 constituting a Wheatstone bridge; a bridge trimming resistor 12 is arranged between the pad 11 and the bridge resistor 10 .

[0022] Both the ceramic ring 2 and the ceramic elastic diaphragm 1 in this design can be designed in a square or circular structure, which can meet the needs of different occasions, reduce manufacturing costs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com