Water lubrication composite thrust bearing of nuclear main pump

A composite material and thrust bearing technology, used in bearings, flexible bearings, bearing components, etc., can solve the problems of incompatibility with the use requirements of high-power nuclear main pumps, hidden dangers of nuclear main pump operation safety, unstable connections, etc., and achieve good water quality. Lubrication properties, good radiation resistance, thickness reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

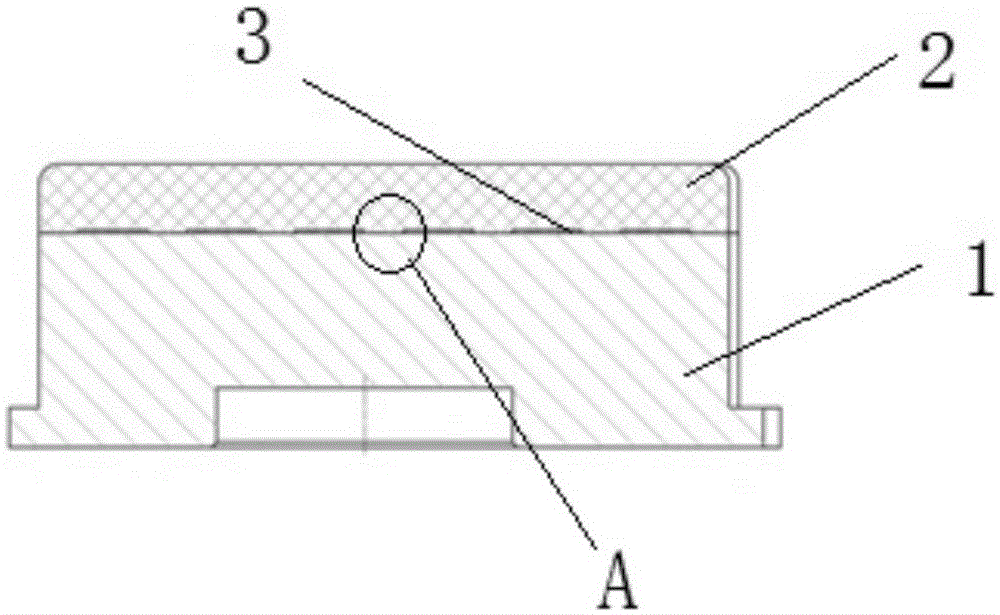

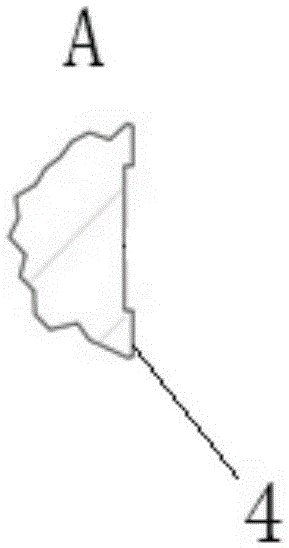

[0067] like figure 1 , figure 2 and Figure 4 As shown, a nuclear main pump water-lubricated composite thrust bearing includes a stainless steel tile base 1 and an engineering plastic layer 2, the stainless steel tile base 1 is fan-shaped, and the stainless steel tile base 1 has a joint connecting the engineering plastic layer 2 A concave-convex surface 3, the concave-convex surface 3 is located on the upper surface of the stainless steel tile base 1, the thickness of the engineering plastic layer 2 is 2-15mm,

[0068] The engineering plastic layer 2 is a composite engineering plastic layer, and the composite engineering plastic layer includes a modified layer and a non-modified layer, and the modified layer is connected with the concave-convex surface 3 through the non-modified layer, so The material of the modified layer is modified polyether ether ketone powder or modified polyether sulfone ketone powder, and the material of the non-modified layer is pure resin powder. ...

Embodiment 2

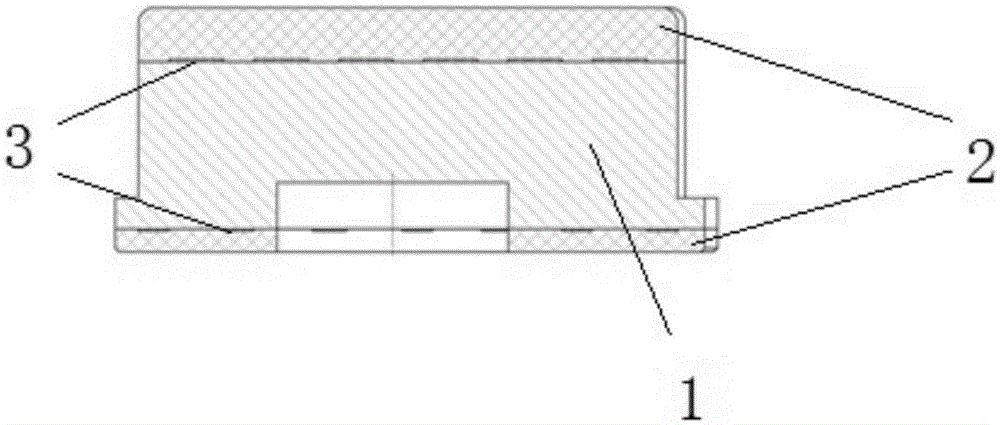

[0081] like image 3 and Figure 4 As shown, compared with the nuclear main pump water-lubricated composite thrust bearing disclosed in Embodiment 1, the difference of this embodiment is that the upper surface of the stainless steel tile base 1 and the lower surface of the stainless steel tile base 1 are both provided with With the concave-convex surface 3 disclosed in Example 1, in the step (4) disclosed in Example 1, it is necessary to calculate and weigh the two parts of the engineering plastic layer located on the upper and lower surfaces of the stainless steel tile base 1 respectively. 2. The required amount of the modified polyether ether ketone resin powder or the modified polyether sulfone ketone resin powder, and the amount of the pure resin powder,

[0082] Afterwards, the amount of the modified polyether ether ketone resin powder or the modified polyether sulfone ketone resin powder required for the engineering plastic layer on the lower surface of the stainless st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com