Spindle dry-type-running magnetic drive pump

A magnetic pump and spindle technology applied in the field of magnetic pumps to achieve low vibration, easy maintenance, and reduced processing difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

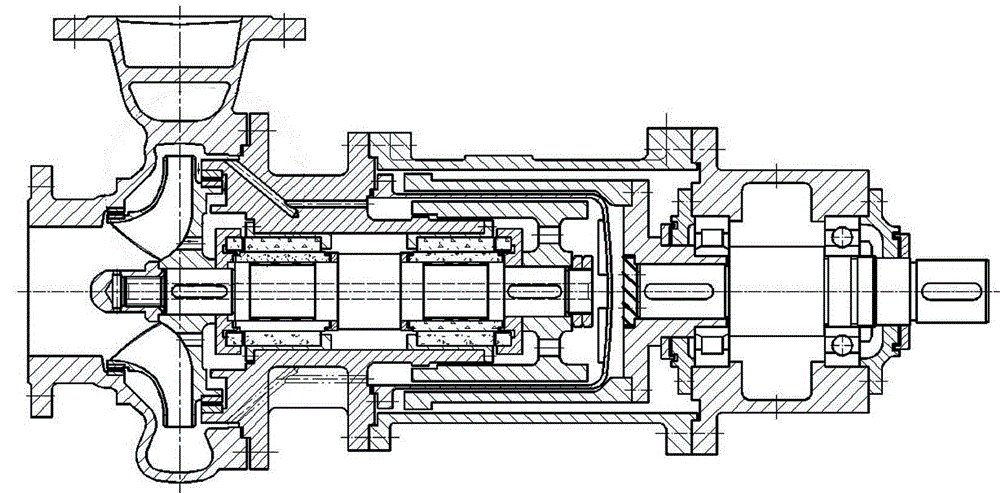

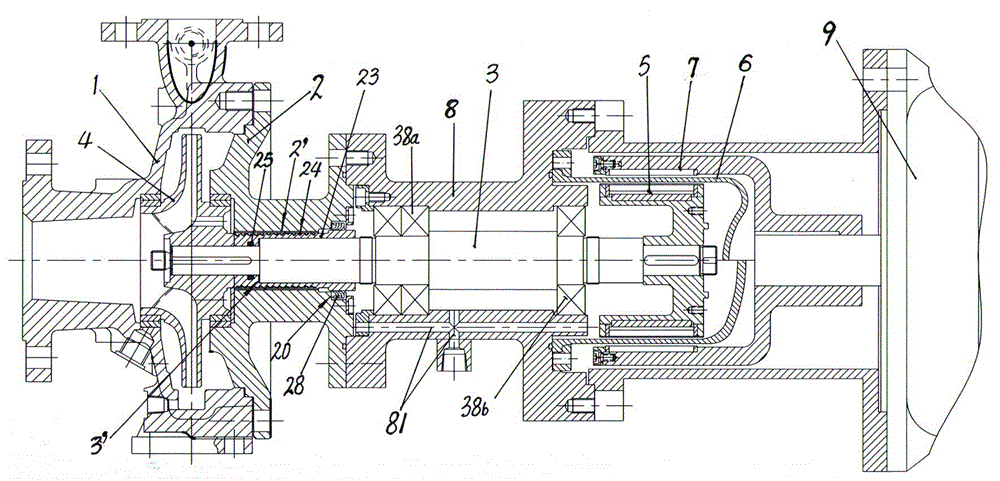

Image

Examples

Embodiment Construction

[0009] specific implementation

[0010] The magnetic pump of the present invention includes a pump body 1, a pump cover 2, a main shaft 3, an impeller 4, an inner magnetic rotor 5, an isolating sleeve 6, an outer magnetic rotor 7, a connecting frame 8, and a bearing housing 9, and the isolating sleeve 6 and the connecting frame 8 are sealed and fixed Connection, which is characterized in that a shut-off sleeve 23 is provided between the shaft hole 2' of the pump cover 2 and the pump shaft 3, and a spiral groove 24 is opened on the outer ring surface of the shut-off sleeve 23, and the spiral groove 24 is formed in cooperation with the shaft hole of the pump cover 2 The spiral pumping ring reversely pumps the medium that enters the shaft hole 2' of the pump cover in the pump cavity. There is a stopper 20 at the port of the shaft hole 2' of the pump cover. Inside the stopper 20 Install the stainless steel rotary oil seal sealing ring device 28 that cooperates with the outer rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com