Method and device for preparing magnetostrictive material

A technology of magnetostrictive materials and materials, applied in the field of materials, can solve the problems such as the inability to fundamentally change the orientation degree of the original polycrystalline material, the limited improvement of the magnetostrictive properties of the materials, and the large fluctuations in composition and performance, and achieve volatilization. The effect of less, less temperature gradient, and uniform composition of the finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

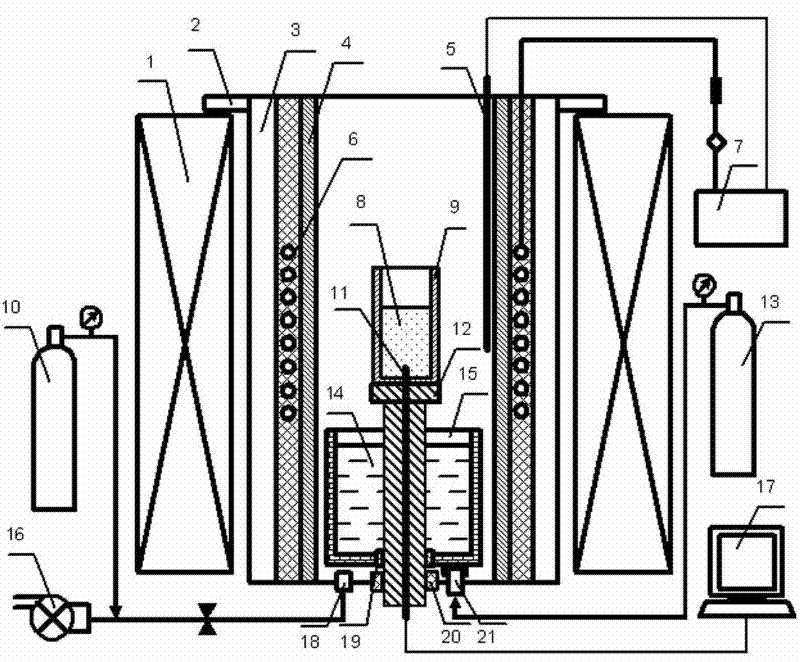

[0033] The structure of the device for preparing magnetostrictive materials is as follows figure 1 As shown, including strong magnet 1, heating furnace, crucible 9, support 12 and cooling medium container 15, heating furnace is arranged in the cavity inside strong magnet 1, and heating furnace is fixed together with strong magnet 1 by fixing plate 2;

[0034] The outer side of the furnace wall 4 of the heating furnace is covered with a heating coil 6, and the heating coil 6 is covered with a cooling water jacket 3; the crucible 9 is arranged inside the heating furnace, and the bottom of the crucible 9 is fixed above the bracket 12;

[0035] The lower end of the bracket 12 is fixed on the fixed sleeve 20 of the heating furnace bottom plate, the fixed sleeve 20 is fixed on the heating furnace bottom plate, and the bracket 12 is covered with a sealing ring to seal the gap between the bracket 12 and the fixed sleeve 20;

[0036]The bottom plate of the cooling medium container 15 i...

Embodiment 2

[0050] The device structure for preparing the magnetostrictive material is the same as in Example 1;

[0051] The inert gas used is nitrogen; the cooling medium container used is 304 stainless steel;

[0052] Place Fe and Tb in a vacuum electric arc furnace and evacuate to 4×10 -4 Pa filled with argon, smelted to prepare Tb-Fe master alloy, the atomic ratio of Tb-Fe master alloy is Tb:Fe=0.66:1;

[0053] Using the device of Example 1, the Tb-Fe master alloy is placed in the crucible in the heating furnace, and the heating furnace is evacuated to a vacuum degree≤10 -3 Pa, then pass inert gas to normal pressure;

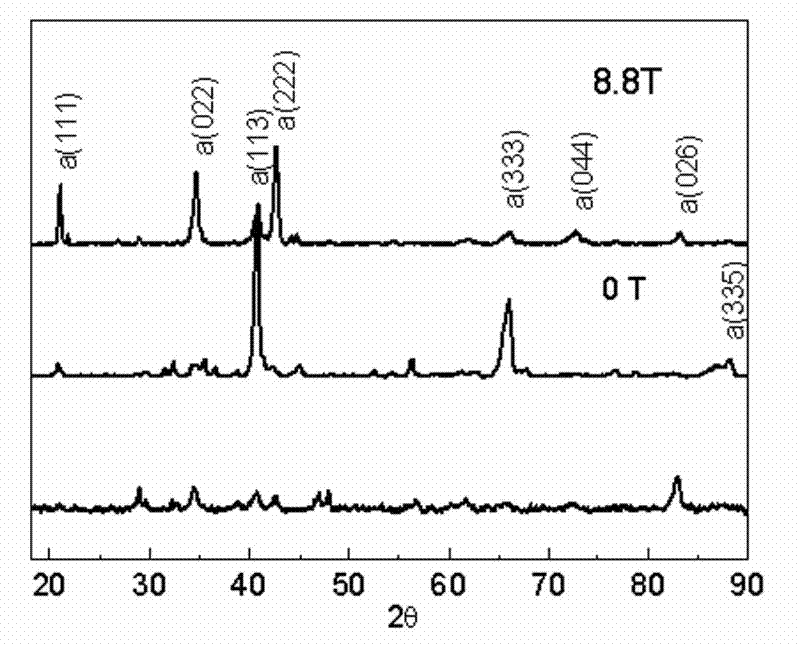

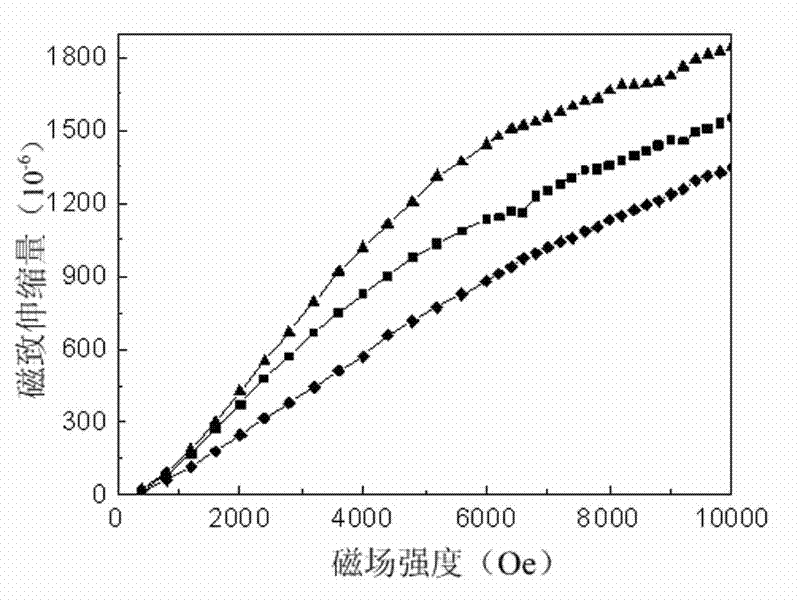

[0054] Then apply a uniform magnetic field with a strength of 11T to the Tb-Fe master alloy, heat the Tb-Fe master alloy into a semi-solid material under the conditions of the magnetic field and inert gas, and keep it warm for 40 minutes for isothermal treatment; the semi-solid material is formed from a liquid matrix Composed of solid and functional phases; the matr...

Embodiment 3

[0058] The device structure for preparing the magnetostrictive material is the same as in Example 1;

[0059] The crucible material used is boron nitride;

[0060] Place Fe and Tb in a vacuum electric arc furnace and evacuate to 4×10 -4 Pa filled with argon, smelted to prepare Tb-Fe master alloy, the atomic ratio of Tb-Fe master alloy is Tb:Fe=0.75:1;

[0061] Using the device of Example 1, the Tb-Fe master alloy is placed in the crucible in the heating furnace, and the heating furnace is evacuated to a vacuum degree≤10 -3 Pa, then pass inert gas to normal pressure;

[0062] Then apply a uniform magnetic field with a strength of 18T to the Tb-Fe master alloy, heat the Tb-Fe master alloy into a semi-solid material under magnetic field conditions and inert gas conditions, and keep it warm for 50 minutes for isothermal treatment; the semi-solid material is formed from a liquid matrix Composed of solid and functional phases; the matrix is Fe, and the functional phase is TbFe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com