Continuous preparation device and continuous preparation method for nanofiber yarns

A nanofiber and preparation device technology, applied in dry spinning method, stretch spinning method, etc., can solve the problems of no twisting of nanofiber yarn, limited length of nanofiber bundle, difficulty in product processing and application, and achieve the degree of orientation Good, promoting rapid development, simple and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] At the same time, the present invention discloses a nanofiber yarn continuous preparation method based on the above-mentioned nanofiber yarn continuous preparation device, which includes the following steps:

[0031] Step 1: adding a spinning solution into the solution jet spinning die, and the spinning solution is stretched, thinned, and solvent volatilized under the action of the solution jet spinning die to form scattered nanofibers;

[0032] Step 2: Connect the air inlet of the auxiliary air injection device to a compressed air source, and eject an obliquely downward airflow from the air injection pipe, and the nanofibers are straightened and accelerated Twisting and gathering to form nanofiber yarn bundles;

[0033] Step 3: The nanofiber yarn bundle enters the Venturi tube receiving system through the funnel-shaped yarn guide tube, and passes through the yarn guide roller under the vacuum adsorption of the Venturi tube receiving system. The bobbins are wound and c...

Embodiment 1

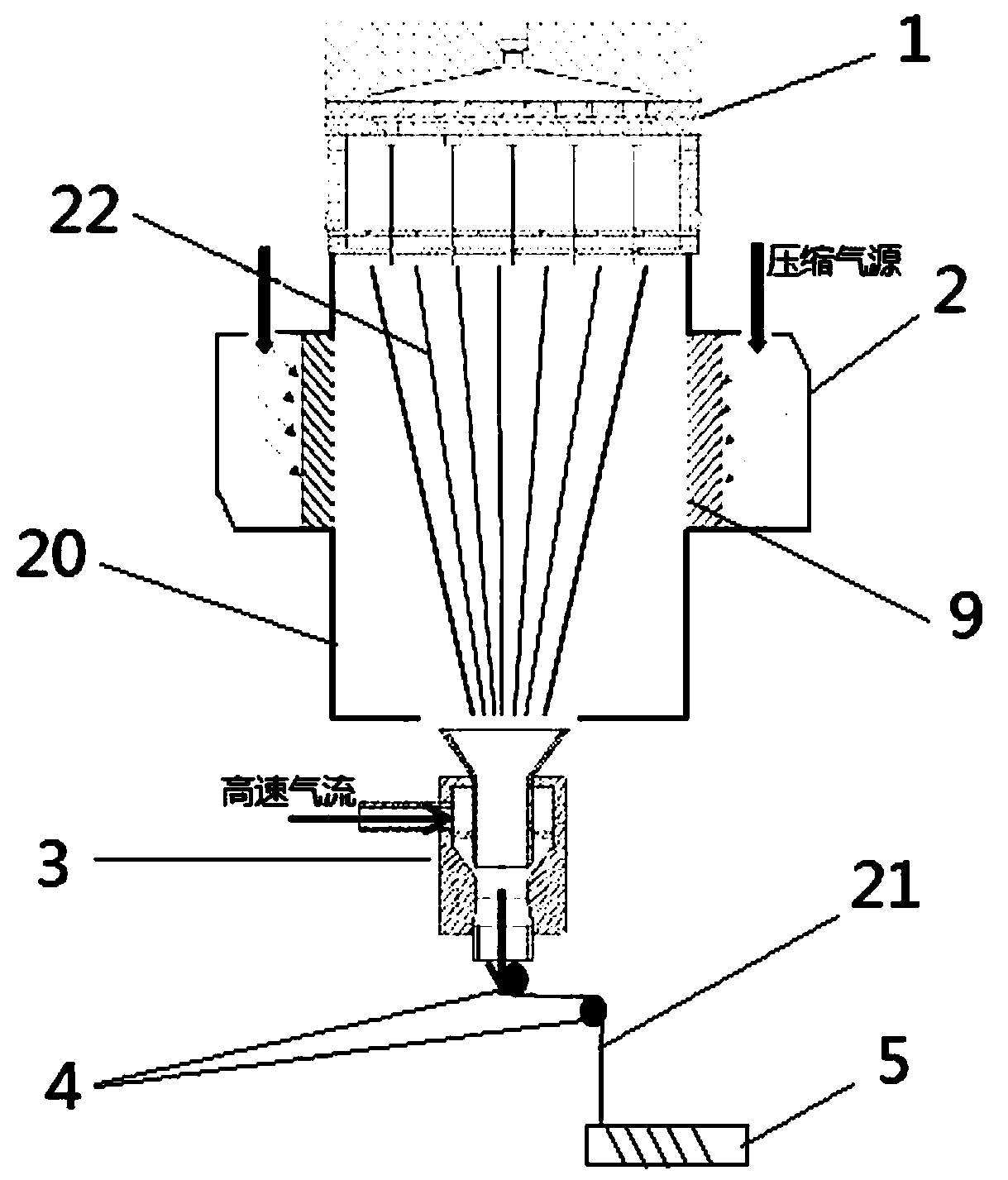

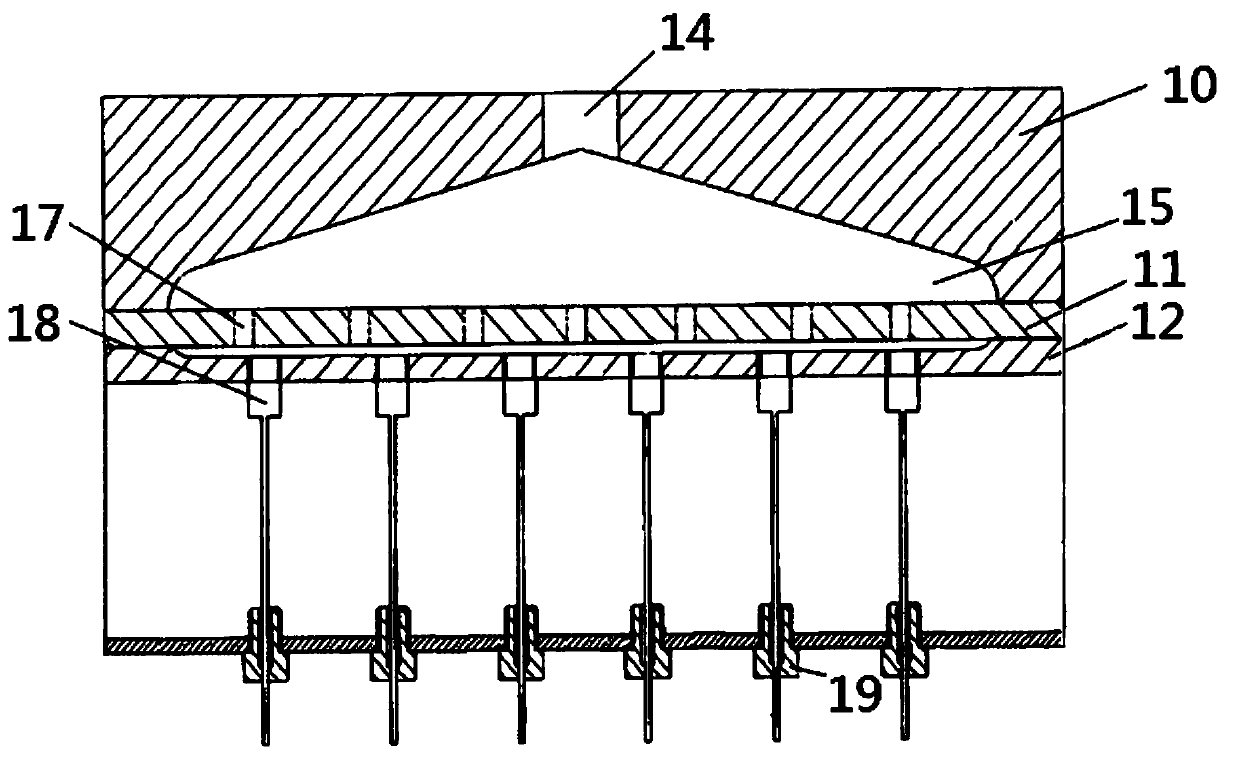

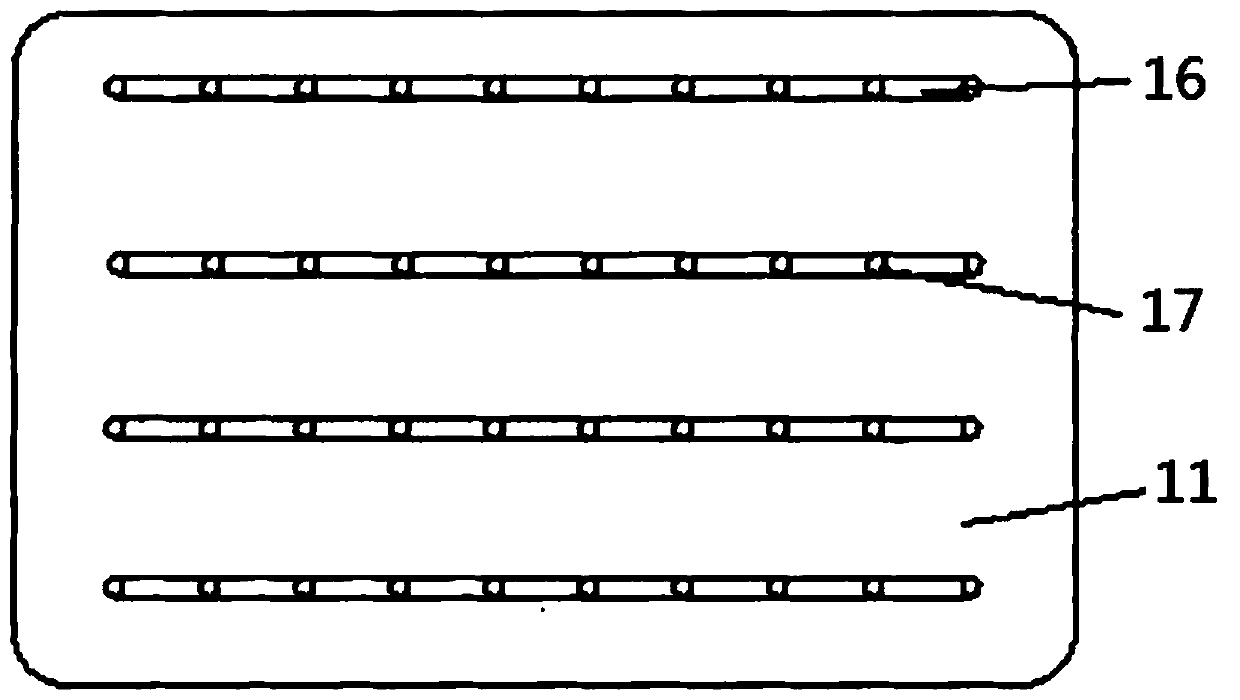

[0038] Such as figure 1 As shown, the present embodiment provides a continuous preparation device for nanofiber yarn, including a solution jet spinning die head 1, an auxiliary air jet device 2, a Venturi tube receiving system 3, a guide roller 4 and a bobbin 5, and the solution jet The spinning die head 1 is used to spray and generate scattered nanofibers 22, and the Venturi tube receiving system 3, the guide roller 4 and the bobbin 5 are sequentially arranged below the solution jet spinning die head 1; where as Figure 4 As shown, the Venturi tube receiving system 3 includes an air drafting nozzle 6, a funnel-shaped yarn guide tube 7 and a high-speed air pipe 8. One side of the stretch nozzle 6, and one end of the high-speed air pipe 8 communicates with the inside of the air-flow drafting nozzle 6, and the other end of the high-speed air pipe 8 is used to connect the high-speed air source; The air inlet of device 2 is connected with a compressed air source, and the inner si...

Embodiment 2

[0052] This embodiment provides a continuous preparation method for nanofiber yarn, which is based on the continuous preparation device for nanofiber yarn described in Example 1. In this embodiment, the structure and working principle of the continuous preparation device for nanofiber yarn All are the same as those in Embodiment 1, and will not be repeated here. Described nanofiber yarn continuous preparation method specifically comprises the following steps:

[0053] Step 1: Add spinning solution to the solution jet spinning die head 1, the spinning solution enters the feeding chamber 15 through the feeding hole 14 through the metering pump, and after distributing the horizontal guide groove on the distribution plate 11, the spinning solution is fed by The distribution holes 17 evenly enter each spinneret capillary 18, and the spinning solution is stretched, thinned, and solvent volatilized under the action of the solution jet spinning die to form nanofibers 22, which are sca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com