Graphitized film and preparation method and application thereof

A technology of graphitization and graphene, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of easy cracking, large shrinkage, low surface flatness, etc., to improve thermal conductivity, increase the degree of orientation, Avoid the effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

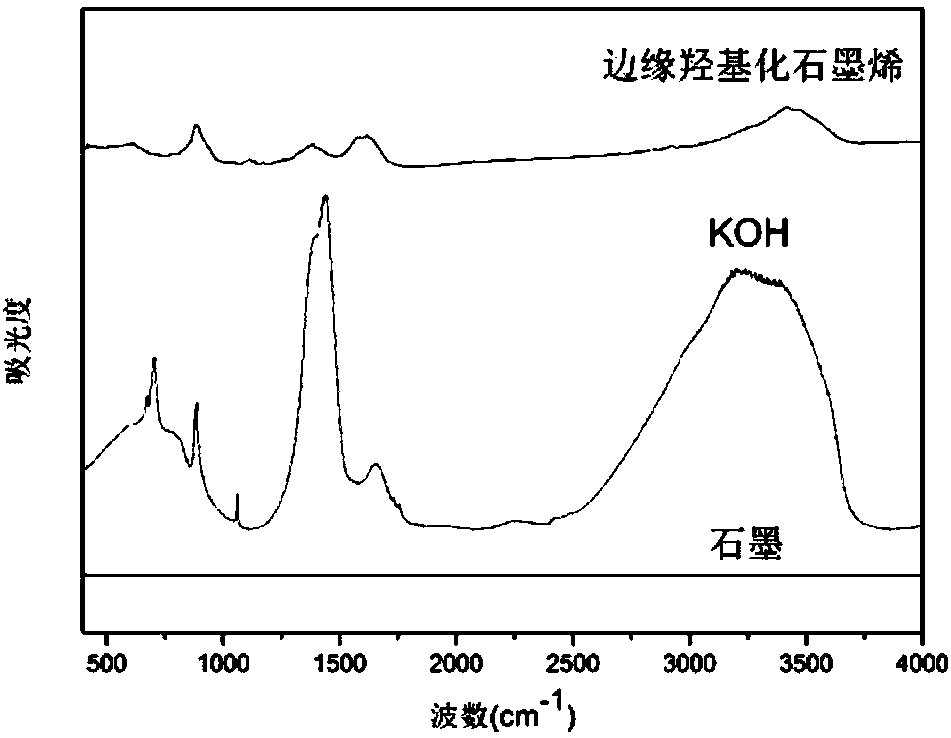

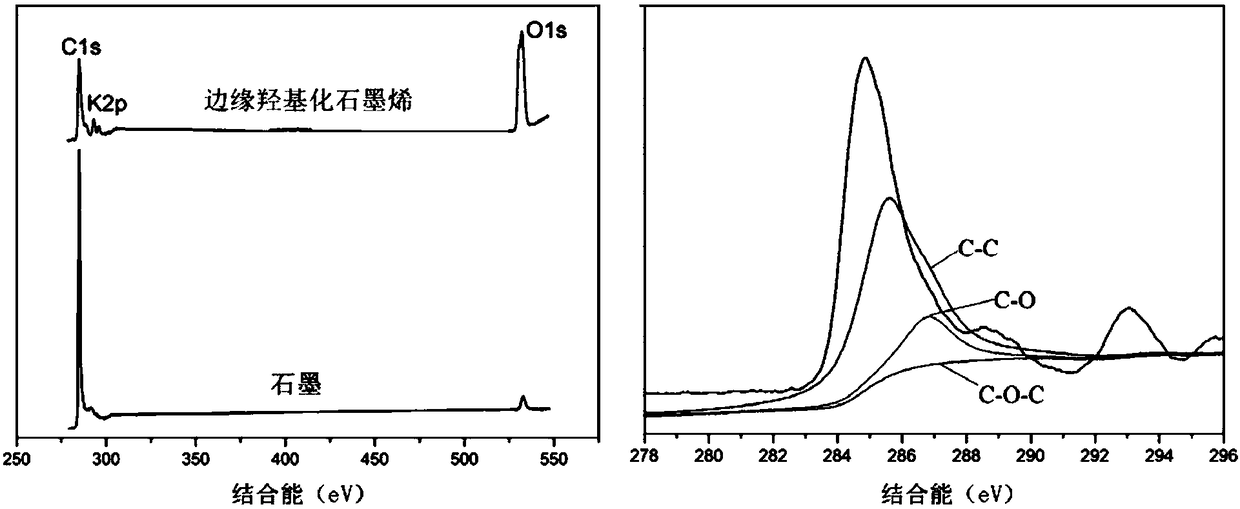

[0052] Graphite (5g) and KOH (200g) were mixed into a ball mill jar equipped with stainless steel grinding balls, and rotated for 12 hours at a speed of 500rpm and in forward and reverse mode (every 30min interval of 1min and then reversed for 30min). The resulting product was removed with deionized water (100 mL) and centrifuged at 4000 rpm for 20 min to retain the supernatant, then pour the supernatant into a dialysis bag and dialyze in deionized water for 48 h to remove K + . The resulting solution was freeze-dried at -60°C for 60 h, and it was confirmed by characterization that edge hydroxylated graphene was obtained, with a yield of 4.8 g.

preparation example 2

[0054] Graphite (5g) and dry ice (75g) were mixed into a ball mill jar equipped with stainless steel grinding balls, and rotated for 48 hours at a speed of 200rpm in forward and reverse mode (every 30min interval of 1min and then reversed for 30min). The obtained product was directly removed, and then Soxhlet extraction was performed on it with hydrochloric acid solution (1M 100mL) (heating temperature was 100°C, heating time was 2.5h), to make it completely acidified, and finally it was freeze-dried at -120°C for 24h, and the Characterization confirmed that edge carboxylated graphene was obtained with a yield of 4.6 g.

Embodiment 1

[0056] This embodiment is used to illustrate the graphitized film of the present invention and its preparation method and application.

[0057] (1) Ultrasonic dispersion of edge hydroxylated graphene (0.58g) and p-phenylenediamine (PPD, 0.89g) prepared in Preparation Example 1 in N,N'-dimethylacetamide (20mL ), to obtain a uniform and stable dispersion;

[0058] (2) Add biphenyltetracarboxylic dianhydride (BPDA, 2.44g) in step (1), adopt the method for low-temperature in-situ polymerization to react at 0 DEG C for 2h, make graphene / polyamic acid mixed solution, solution solid The content is 15% by weight, the viscosity is 2500cP, and the weight ratio of graphene and polyamic acid is 15:100;

[0059] (3) cast the mixed solution obtained in step (2) into a film after defoaming by standing method to obtain a graphene / polyamic acid composite film, and the content of the organic solvent in this film is 40% by weight;

[0060] (4) Biaxially stretch the film obtained in step (3), w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com