A kind of preparation method of chopped fiber oriented mat

A chopped fiber and fiber orientation technology, which is applied in fiber raw material processing, synthetic cellulose/non-cellulose material pulp/paper, papermaking, etc., can solve problems such as complex orientation devices, low degree of orientation of chopped fibers, and environmental pollution , to achieve the effects of improved mechanical properties, high degree of orientation, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

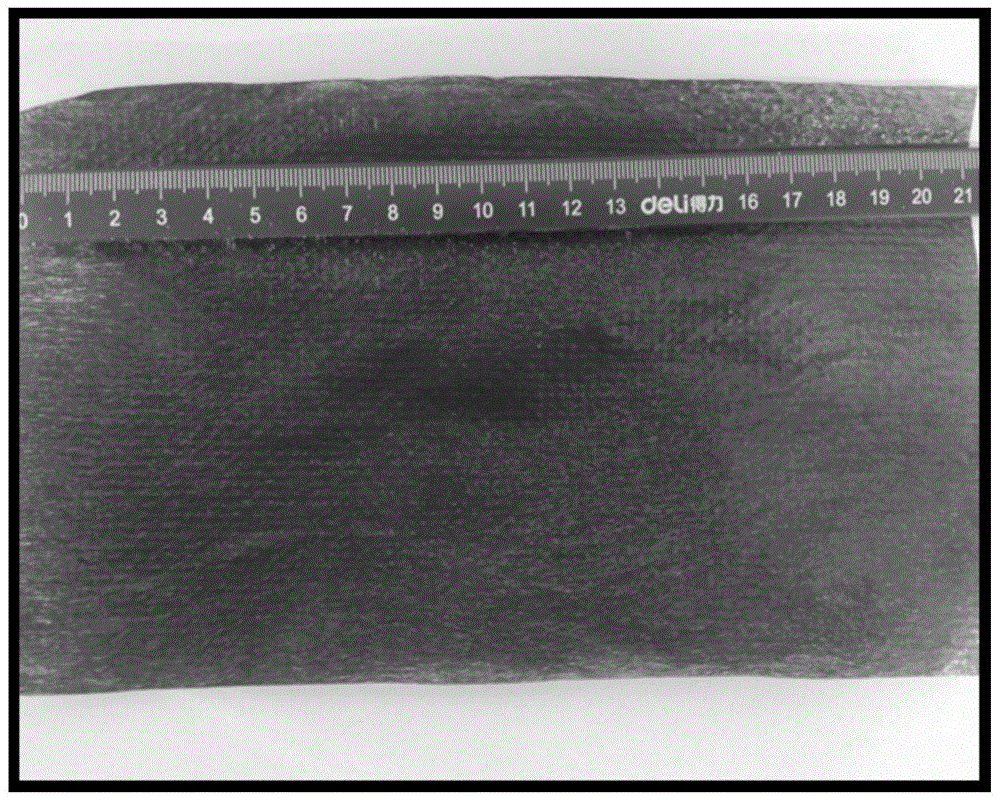

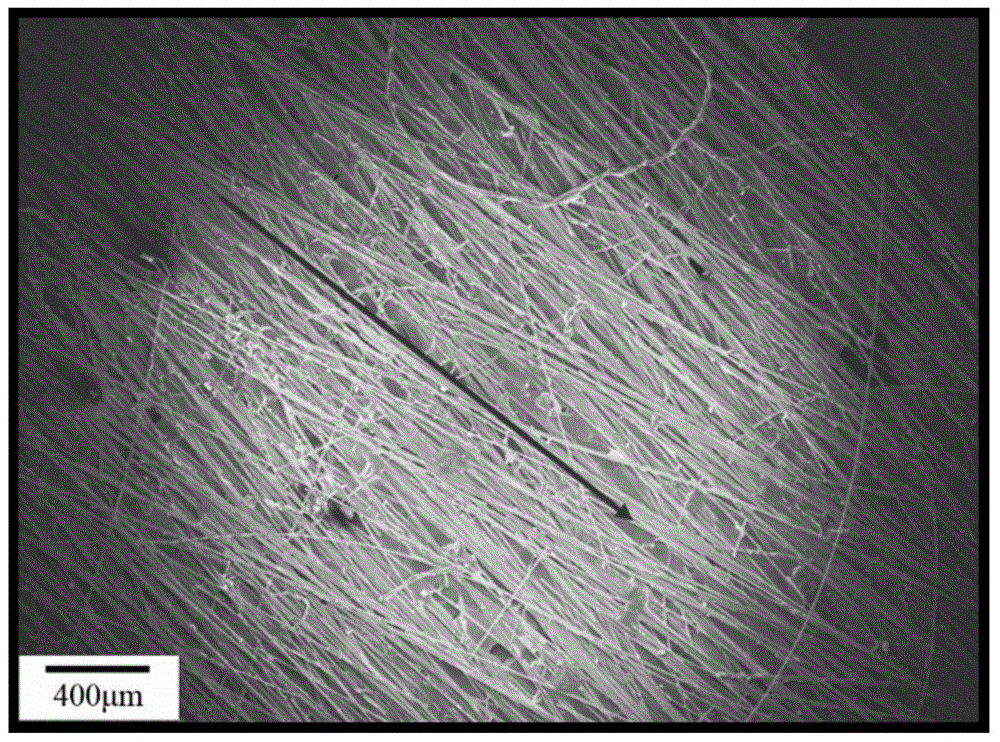

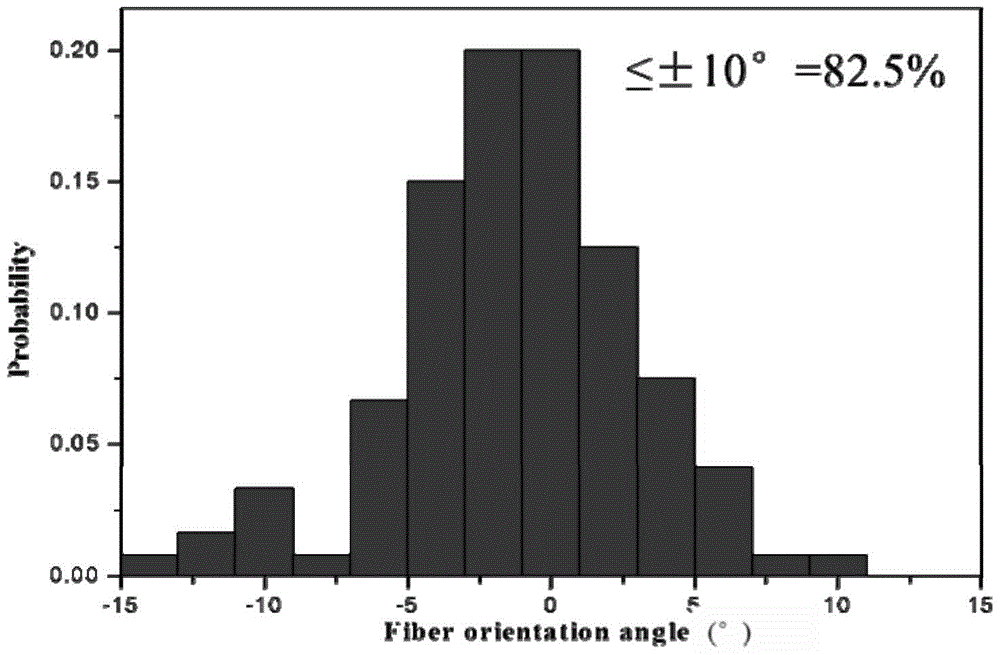

[0026] 1) Fiber dispersion: Put chopped fibers, methyl cellulose and water into a stirring tank and stir evenly at a stirring speed of 600r / min for 30 minutes, and the chopped fibers are uniformly distributed in the form of monofilaments. Wherein the fiber is chopped carbon fiber, the length is 4mm, the content (percentage by weight) is 0.1%, the amount of methyl cellulose added is 13g / L, the actual measured viscosity of the suspension is 8.539Pa.s, and the gas content of the suspension is 4%. .

[0027] 2) Fiber orientation: Press the uniformly dispersed chopped fiber suspension in 1) into the tapered orientation nozzle through the air compressor, the length of the orientation nozzle is 10cm, the included angle of the flow channel is 30°, and the nozzle width of the orientation nozzle is 1.0mm , use the tapered orientation nozzle to orient the short fibers, and continuously feed them into the continuously running conveyor belt to obtain a uniformly distributed fiber-oriented ...

Embodiment 2

[0033] 1) Fiber dispersion: Put chopped fibers, methyl cellulose and water into a stirring tank and stir evenly at a stirring speed of 1000r / min for 20 minutes, and the fibers are uniformly distributed in the form of monofilaments. Wherein the fiber is chopped glass fiber, the length is 3mm, the content (percentage by weight) is 0.8%, the methylcellulose addition is 8g / L, the actual measurement suspension viscosity is 1.056Pa.s, and the suspension gas content rate is 8 %.

[0034]2) Fiber orientation: Press the uniformly dispersed chopped fiber suspension in 1) into the tapered orientation nozzle through the air compressor, the length of the orientation nozzle is 10cm, the included angle of the flow channel is 40°, and the nozzle width of the orientation nozzle is 0.5mm , use the tapered orientation nozzle to orient the short fibers, and continuously feed them into the continuously running conveyor belt to obtain a uniformly distributed fiber-oriented wet mat. Among them, the...

Embodiment 3

[0039] 1) Fiber dispersion: put the chopped fiber, methyl cellulose and water into the mixing tank and stir evenly, the stirring speed is 500r / min, the time is 60min, and the fiber is uniformly distributed in the form of monofilament. Wherein the fiber is chopped polyimide fiber, the length is 6mm, the content (percentage by weight) is 0.2%, the addition of methylcellulose is 6g / L, the actual measurement suspension viscosity is 0.591Pa.s, and the suspension contains gas The rate is 9%.

[0040] 2) Fiber orientation: Press the uniformly dispersed chopped fiber suspension in 1) into the tapered orientation nozzle through the air compressor, the length of the orientation nozzle is 25cm, the included angle of the flow channel is 20°, and the nozzle width of the orientation nozzle is 1.5mm , use the tapered orientation nozzle to orient the short fibers, and continuously feed them into the continuously running conveyor belt to obtain a uniformly distributed fiber-oriented wet mat. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com