Preparation method and application of composite film

A composite film and carbon nanotube composite technology, which is applied in textiles and papermaking, optics, fiber processing, etc., can solve the problems of easy dispersion and deformation, opaque fiber film, and unsatisfactory application, so as to achieve the diversification of preparation methods and improve phase The effect of capacitive and size adjustable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

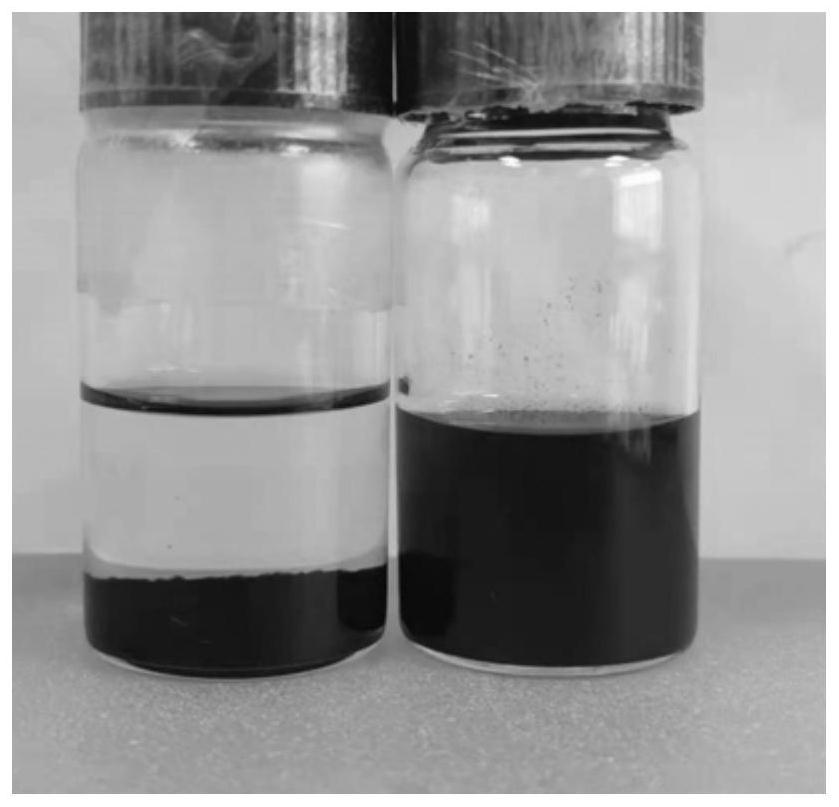

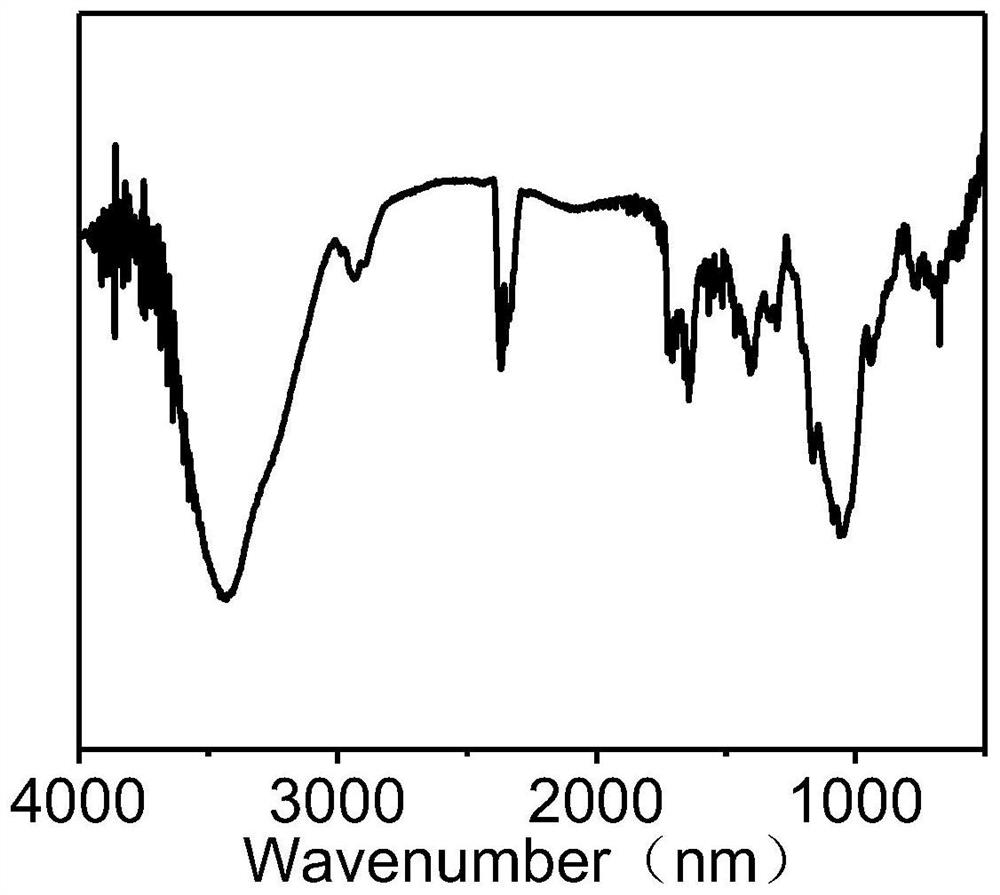

[0037]1) Disperse 0.1 g of multi-walled carbon nanotubes in 10 g of ethanol: water = 1:1 solvent, sonicate for 5 minutes with a sonicator, adjust to pH = 4 with hydrochloric acid, and add 0.5 g of silane coupling agent dropwise The mixed solution was magnetically stirred for 12 hours, then washed with ethanol, centrifuged and dried at 60° C. for 12 hours to obtain the modified carbon nanotubes. Its infrared spectrum is shown in figure 2 .

[0038] 2) Dissolve 0.9g PMMA in 4.055g TCM, add 0.0045g modified carbon nanotubes and stir for 12h to form a uniform spinning solution.

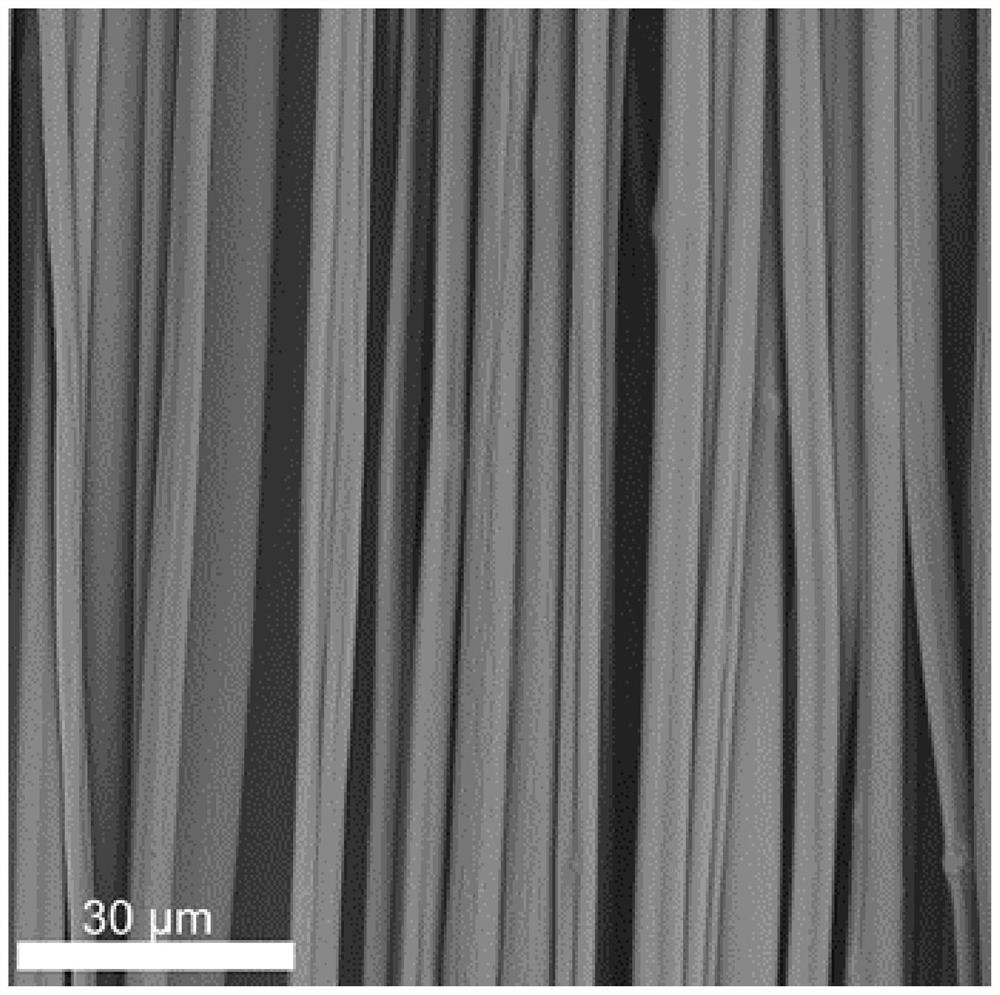

[0039] 3) Add the spinning solution into the syringe and fix it on the syringe pump. The distance from the needle to the drum is 20cm, the flow rate is 2mL / h, the drum speed is 1500r / min, the spinning voltage is 18kV, and the inner diameter of the flat needle is 0.61 mm, the outer diameter is 0.91mm, and the oriented carbon nanotube / PMMA composite fiber membrane is prepared. Remove the fiber film with...

Embodiment 2

[0044] 1) Disperse 0.1 g of multi-walled carbon nanotubes in 10 g of ethanol: water = 1:1 solvent, sonicate for 5 minutes with a sonicator, adjust to pH = 4 with hydrochloric acid, and add 0.5 g of silane coupling agent dropwise The mixed solution was magnetically stirred for 12 hours, washed with ethanol, centrifuged and dried at 60° C. for 12 hours.

[0045] 2) Dissolve 0.9g PMMA in 4.073g TCM, add 0.009g modified carbon nanotubes and stir for 12h to form a uniform spinning solution.

[0046] 3) Add the spinning solution into the syringe and fix it on the syringe pump. The distance from the needle to the drum is 20cm, the flow rate is 2mL / h, the drum speed is 1500r / min, the spinning voltage is 18kV, and the inner diameter of the flat needle is 0.61 mm, with an outer diameter of 0.91 mm, to prepare oriented fiber membranes. Remove the fiber film with a certain thickness from the drum and dry it at room temperature.

[0047] 4) Cut the fiber film dried at room temperature in...

Embodiment 3

[0050] 1) Disperse 0.1 g of multi-walled carbon nanotubes in 10 g of ethanol: water = 1:1 solvent, sonicate for 5 minutes with a sonicator, adjust to pH = 4 with hydrochloric acid, and add 0.5 g of silane coupling agent dropwise The mixed solution was magnetically stirred for 12 hours, washed with ethanol, centrifuged and dried at 60° C. for 12 hours.

[0051] 2) Dissolve 0.9g PMMA in 4.073g TCM, add 0.027g modified carbon nanotubes and stir for 12h to form a uniform spinning solution.

[0052] 3) Add the spinning solution into the syringe, fix it on the syringe pump, the distance from the needle to the roller is 20cm, the flow rate is 2mL / h, the rotating speed of the roller is 1500r / min, and the spinning voltage is 18kV to prepare an oriented fiber film. The fiber film with a certain thickness is removed from the drum and dried at room temperature.

[0053] 4) Cut the fiber film dried at room temperature into 80mm×50mm strips, put it into a sealed box filled with ethyl aceta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com