Building formwork forming structure, fasteners and construction method of building formwork

A technology for building formwork and forming structure, which is applied to the on-site preparation of building components, building structure, connection of formwork/formwork/work frame, etc. Screw cost and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

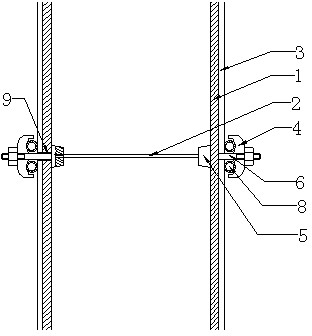

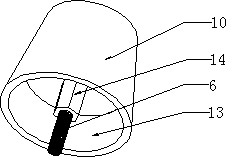

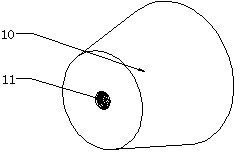

[0022] Such as figure 1 As shown, the building formwork forming structure of the present invention includes a formwork 1, a tension bolt 2, a column 3 and a clamp 4, the formwork is arranged in parallel on both sides of the concrete filling cavity, and there are many pairs of tension bolt holes 9 oppositely arranged on the formwork. Each pair of tension bolt holes is matched with a tension bolt, and the two ends of the tension bolt are threaded to connect a pair of truncated circular fasteners 5; the circular truncated fasteners 5 are arranged inside the two templates, and the The large end surface of the fastener facing the outside is provided with an extended screw 6 that can pass through the pull bolt hole 9 on the template; the protruding part of the extended screw passes through the column 3 on the outside of the template and is tightened and fixed by a conventional clamp 4 .

[0023] A horizontal steel pipe 8 is also pressed between the inner side of the clamp 4 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com