Method for using carbon nano conductive agent in lithium ion battery aqueous slurry

A lithium-ion battery, water-based slurry technology, applied in battery electrodes, circuits, electrode manufacturing and other directions, can solve the problems of unusable, low electronic conductivity, and failure to find better ones, and achieves improved rate, simple method, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

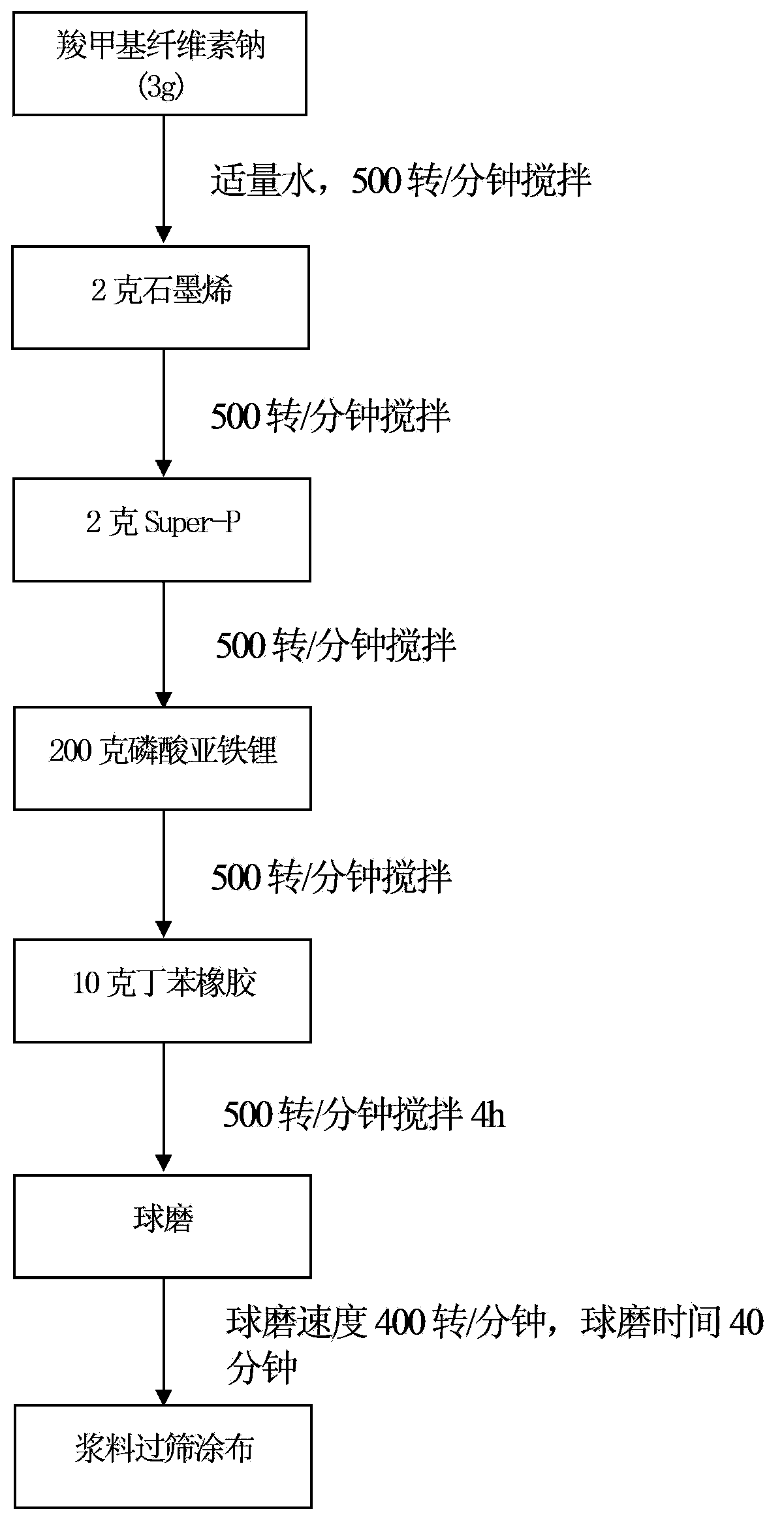

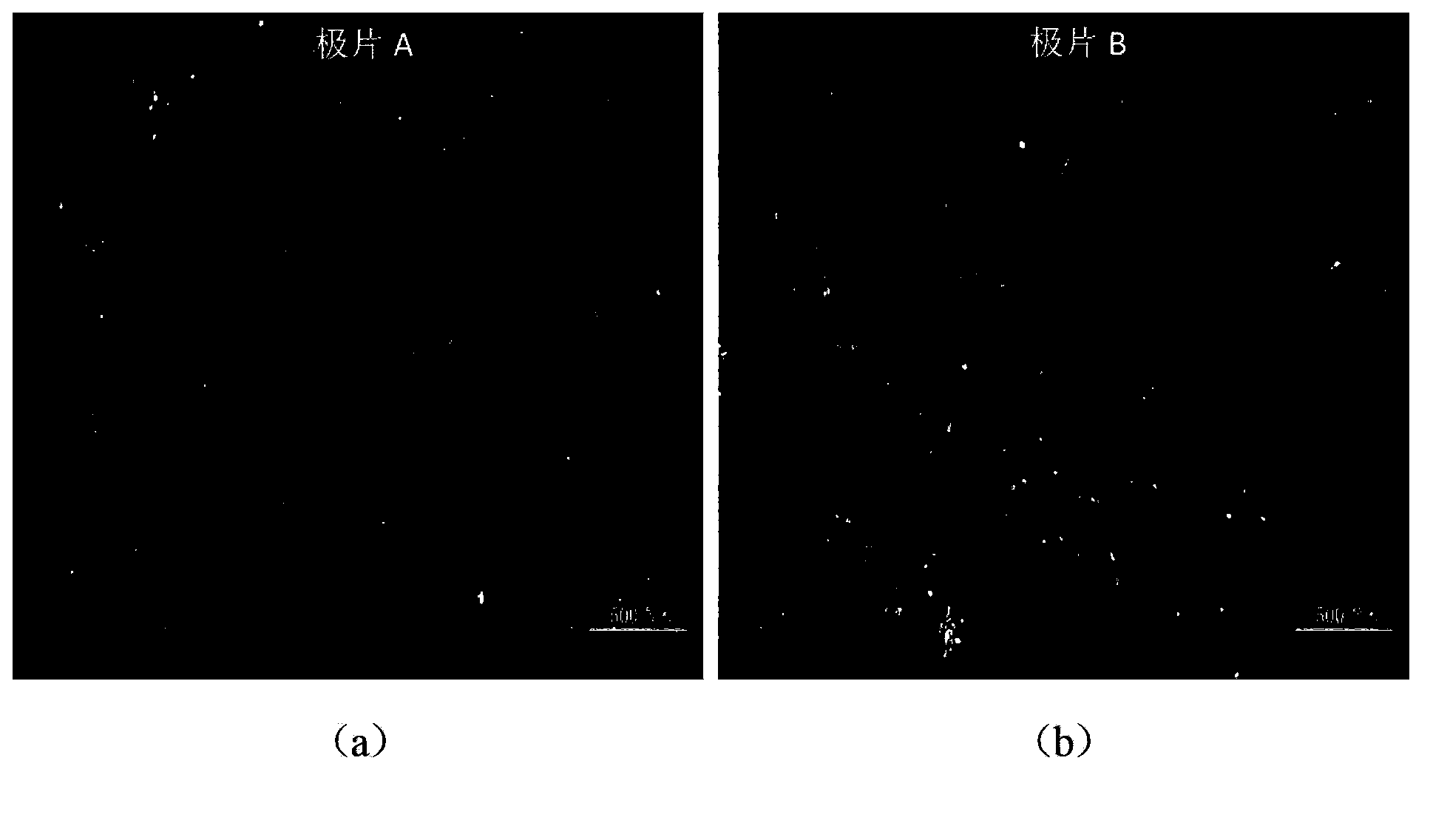

[0031] according to figure 1 The slurry preparation process is used to prepare the pole piece. Weigh 3 grams of sodium carboxymethyl cellulose, add it to a beaker, add 120 grams of water, stir at a speed of 500 rpm until it becomes a transparent colloid, and then add 2 gram of graphene, 2 grams of Super-P, 200 grams of lithium iron phosphate and 10 grams of styrene-butadiene rubber. After stirring for 4 hours, the viscosity of the slurry was adjusted to 7000 mPa·s by adjusting the amount of water added. Then the slurry is ball milled (the ball milling speed is 400 rpm, the ball milling time is 40 minutes, the mass ratio of zirconia balls and slurry is 1:1), and the ball milled slurry is sieved through a 150-mesh screen. According to 10mg / cm 2 The areal density is coated on one side, and then baked in an oven at 80°C for 24 hours. This pole piece is marked as pole piece A. Such as figure 2 As shown in (a), the surface of pole piece A is smooth without defects such as cracks...

Embodiment 2

[0040] Weigh 3 grams of sodium carboxymethyl cellulose, add it to a beaker, add 120 grams of water, stir at a speed of 500 rpm until it becomes a transparent colloid, then add 2 grams of carbon nanotubes, 2 grams of Super-P, 200 grams of lithium iron phosphate and 10 grams of styrene-butadiene rubber (SBR), after stirring for 4 hours, water was added to adjust the viscosity of the slurry to 7000 mPa·s. Then the slurry in the beaker is ball milled (the ball milling speed is 400 rpm, the ball milling time is 40 minutes, the mass ratio of zirconia balls and slurry is 1:1), and then the ball milled slurry is screened with a 150-mesh screen. Sieve, then according to 10mg / cm 2 The areal density is coated on one side, and then baked in an oven at 80°C for 24 hours to obtain a pole piece with excellent processability.

Embodiment 3

[0042] Weigh 3 grams of sodium carboxymethyl cellulose, add it to a beaker, add 120 grams of water, stir at a speed of 500 rpm until it becomes a transparent colloid, then add 1 gram of carbon nanotubes, 1 gram of KS-6 conductive graphite, 2 grams of Super-P, 200 grams of lithium iron phosphate and 10 grams of styrene-butadiene rubber (SBR), after stirring for 4 hours, add water to adjust the viscosity of the slurry to 7000mPa·s. Then the slurry in the beaker is ball milled (the ball milling speed is 500 rpm, the ball milling time is 30 minutes, the mass ratio of zirconia balls and slurry is 1:1), and then the ball milled slurry is screened with a 150-mesh screen. Sieve, then according to 10mg / cm 2 The areal density is coated on one side, and then baked in an oven at 80°C for 24 hours to obtain a pole piece with excellent processability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com