Mixed sand wet mixed mortar and preparation method thereof

A technology of wet-mixing mortar and mixed sand, which is applied in the field of building materials, can solve the problems of shortage of natural river sand resources and the inability of ore sand to replace natural river sand, and achieve the effects of wide sources, convenient construction, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of mixed sand wet-mixed mortar comprises the steps of:

[0041] 1) Mix and stir cement, fly ash, machine-made sand, and tailings sand evenly to obtain a dry mortar mixture;

[0042] 2) Dissolve water reducer, thickener and retarder in 7~12 parts of mixing water, then pour into the dry mortar mixture obtained in step 1), and stir evenly;

[0043] 3) Add the remaining mixing water and continue to mix evenly to obtain a mixed sand wet-mixed mortar.

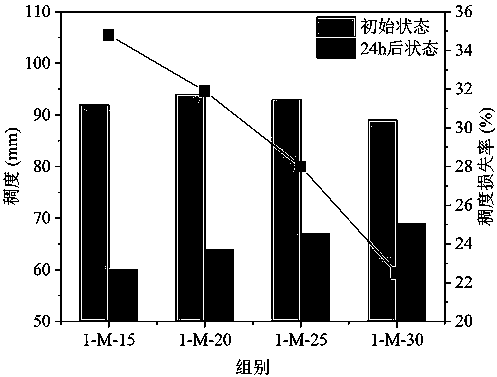

Embodiment 1

[0045] A mixed sand wet-mixed mortar, which is composed of the following materials in parts by weight: 9.8 parts of cement, 4 parts of fly ash, 73.5 parts of mixed sand (including 29.4 parts of machine-made sand and 44.1 parts of tailing sand), and 0.14 parts of water reducer , 0.24 parts of thickener, 0.42 parts of retarder, 11.9 parts of water.

[0046] The cement used is PO42.5 ordinary Portland cement, and the fly ash is Class II fly ash used in construction engineering; the machine-made sand has been washed and de-powdered, the methylene blue index is lower than 0.5, and the fineness modulus is 3.2 to 3.4, the fineness modulus of the tailings sand is 1.1 to 1.3, and the fineness modulus of the mixed sand in this embodiment is 2.1.

[0047] The water reducer is polycarboxylate high-efficiency water reducer, the thickener is hydroxypropyl methylcellulose ether, and the retarder is sodium gluconate. Under the joint action of the three admixtures, the consistency and working...

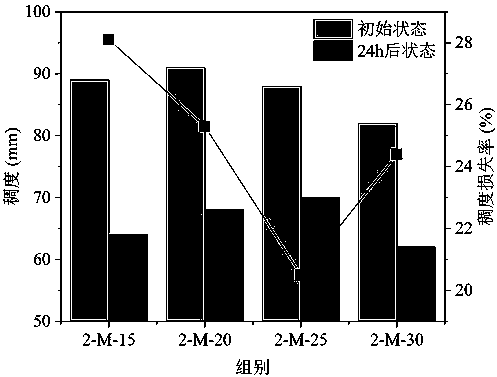

Embodiment 2

[0053] A mixed sand wet-mixed mortar, which is composed of the following materials in parts by weight: 11.7 parts of cement, 4.2 parts of fly ash, 71.1 parts of mixed sand (including 35.4 parts of machine-made sand and 35.7 parts of tailing sand), and 0.15 parts of water reducer , 0.27 parts of thickener, 0.48 parts of retarder, 12.1 parts of water.

[0054] The cement used is PO42.5 ordinary Portland cement, and the fly ash is Class II fly ash used in construction engineering; the machine-made sand has been washed and de-powdered, the methylene blue index is lower than 0.5, and the fineness modulus is 3.2 to 3.4, the fineness modulus of the tailings sand is 1.1 to 1.3, and the fineness modulus of the mixed sand in this embodiment is 2.3.

[0055] The water reducer is polycarboxylate high-efficiency water reducer, the thickener is hydroxypropyl methylcellulose ether, and the retarder is sodium gluconate. Under the joint action of the three admixtures, the consistency and work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com