Salt-free pickling-free amphoteric polymer chrome-free tanning agent

A technology of amphoteric polymer and chrome-free tanning agent, which is applied in animal husbandry, small raw hide/large raw hide/leather skin/fur chemical treatment, application, etc. It can solve the problems of increased organic pollution content, low absorption and utilization rate, and the quality of finished leather. gaps and other issues, to achieve the effects of promoting absorption, low production costs, and simple production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

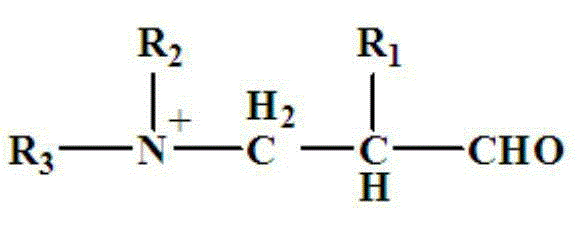

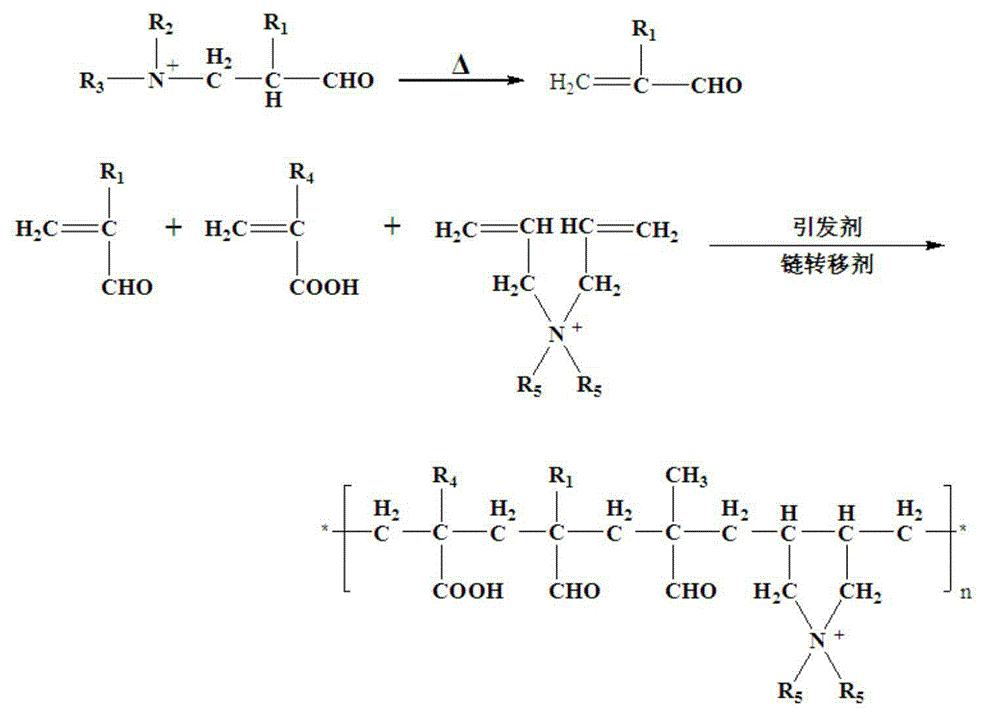

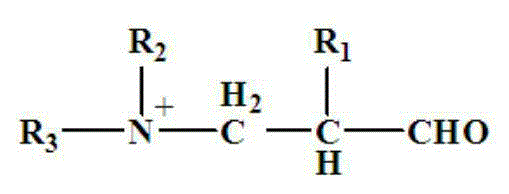

[0032] First add 60Kg of ethanolamine and 100Kg of formaldehyde into the reaction kettle, then add concentrated sulfuric acid to adjust the pH of the reaction system to 6.0-6.5, add 110Kg of acetaldehyde solution (40%), and react at 35-40°C for 5 hours to obtain Mannich base intermediate. Add 300Kg of water, 70Kg of itaconic acid, 165Kg of dimethyl diallyl ammonium chloride, 2Kg of mercaptoethanol to the intermediate, and add persulfuric acid diluted with 100Kg of water to the reaction kettle dropwise after the temperature rises to 75-80°C. The ammonium initiator is 10Kg, and the dropping time is 2 hours. After the dropping, it is kept at 75-80°C for 0.5 hour, and the temperature is lowered to below 50°C, and the material is discharged to obtain the product.

Embodiment 2

[0034] First add 70Kg of diethylamine and 80Kg of formaldehyde into the reaction kettle, then add concentrated sulfuric acid to adjust the pH of the reaction system to 6.5-7.0, add 80Kg of propionaldehyde, and react at 50-55°C for 4 hours to obtain the Mannich base intermediate. Add 350Kg of water, 80Kg of acrylic acid, 145Kg of diethyldiallyl ammonium chloride, 4Kg of n-dodecyl mercaptan to the intermediate, and after the temperature rises to 80-85°C, add dropwise to the reaction kettle diluted with 90Kg of water The sodium persulfate initiator is 9Kg, and the dropping time is 1 hour. After the dropping, it is kept at 80-85°C for 1 hour, and the temperature is lowered to below 50°C, and the material is discharged to obtain the product.

Embodiment 3

[0036] First add 75Kg of monomethylethanolamine and 80Kg of formaldehyde into the reaction kettle, then add concentrated sulfuric acid to adjust the pH of the reaction system to 6.5-7.0, add 60Kg of propionaldehyde, and react at 40-45°C for 3.5 hours to obtain the Mannich base intermediate . Add 400Kg of water, 90Kg of acrylic acid, 125Kg of dimethyl diallyl ammonium chloride, 6Kg of n-dodecyl mercaptan to the intermediate, and after heating up to 85-90°C, add dropwise to the reaction kettle diluted with 80Kg of water Potassium persulfate initiator 8Kg, dropwise time is 1.5 hours, after dropwise addition, keep warm at 80-85°C for 1.5 hours, cool down to below 50°C and discharge to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com