Individual package of absorbent article

a technology of absorbent articles and individual packages, which is applied in the direction of flexible article containers, sanitary towels, catheters, etc., can solve the problems of high difficulty in opening the package for large anti-peeling resistance, and the generation of husky or crinkly nois

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

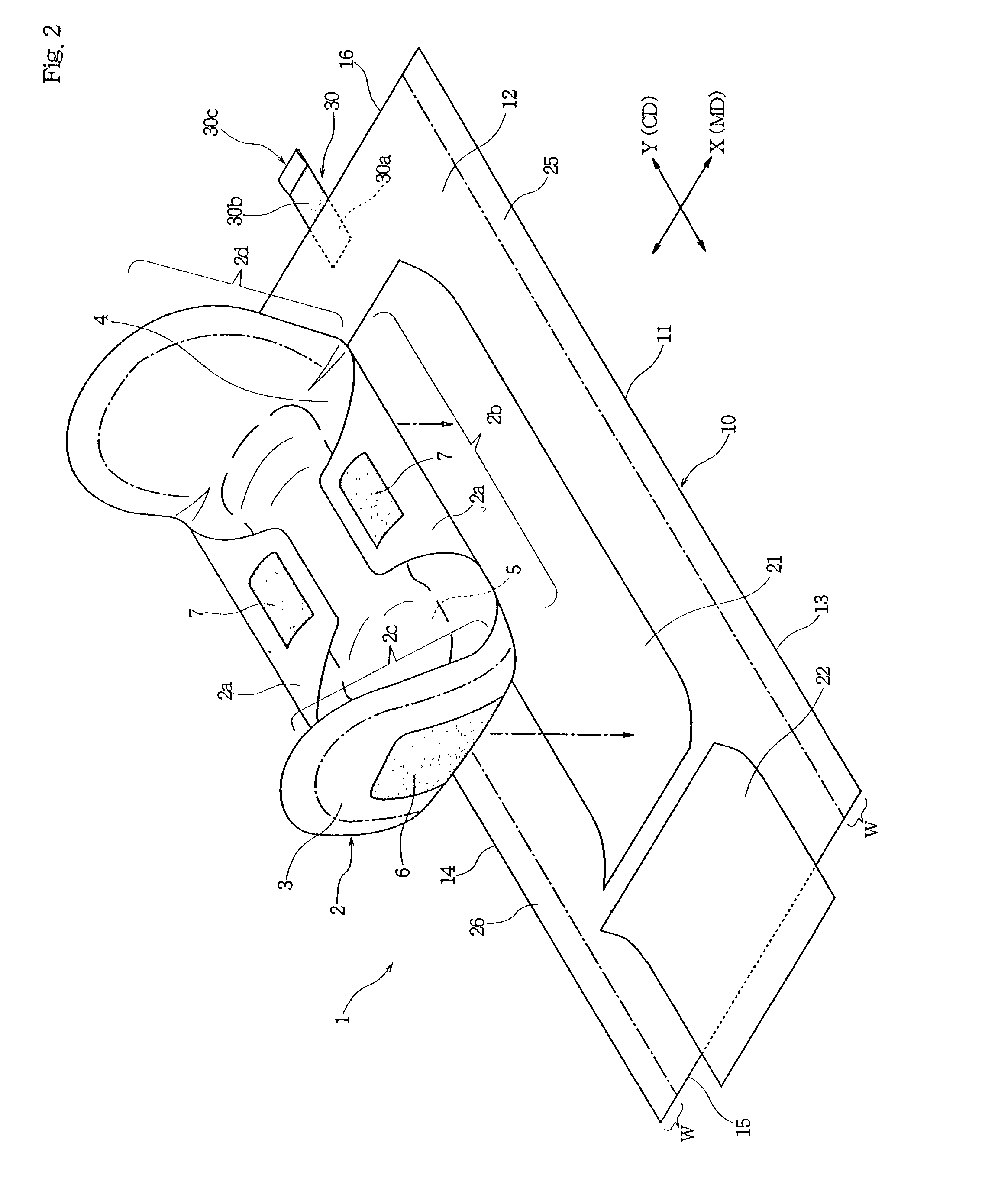

example 1

(2) Example 1

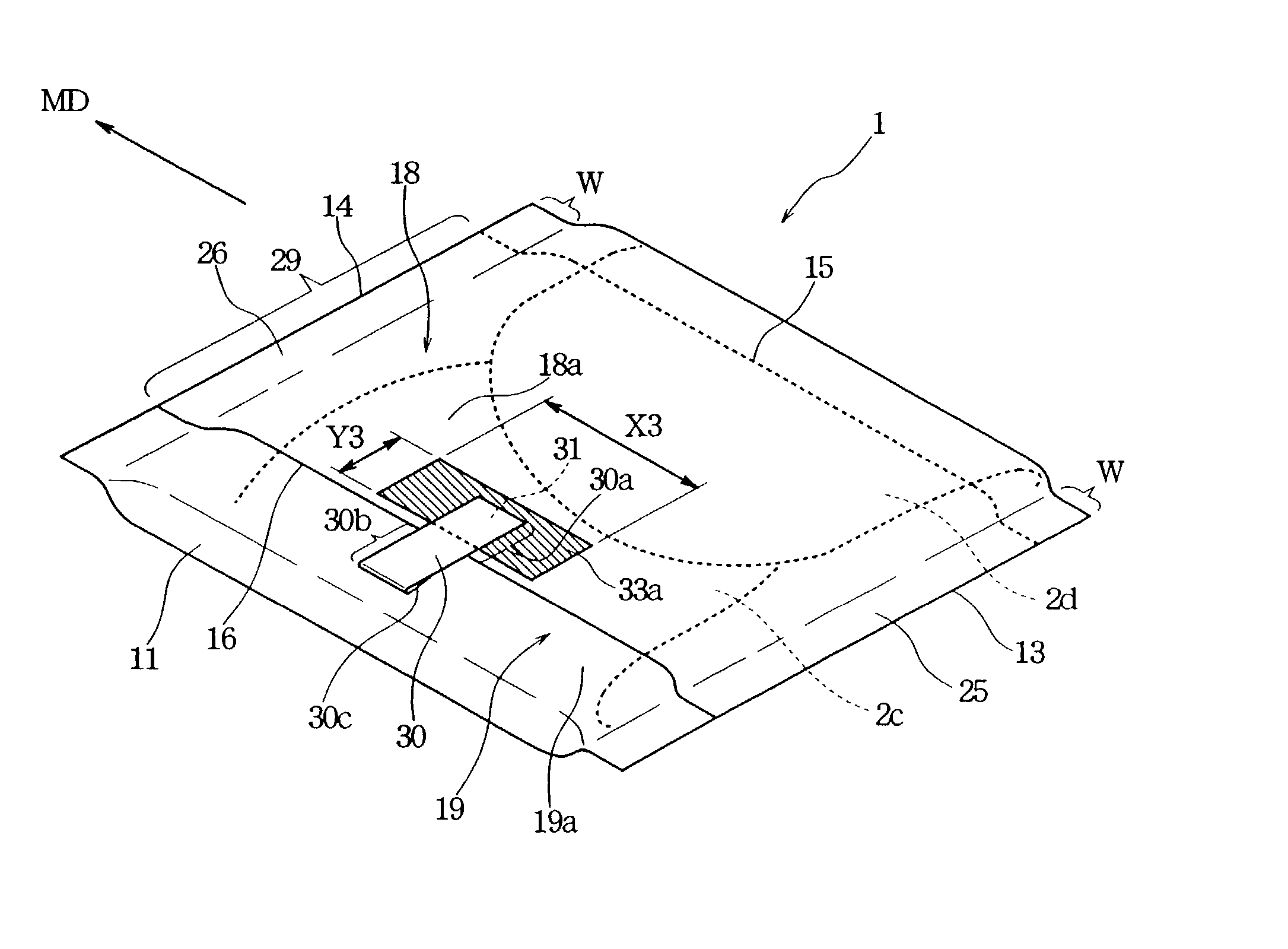

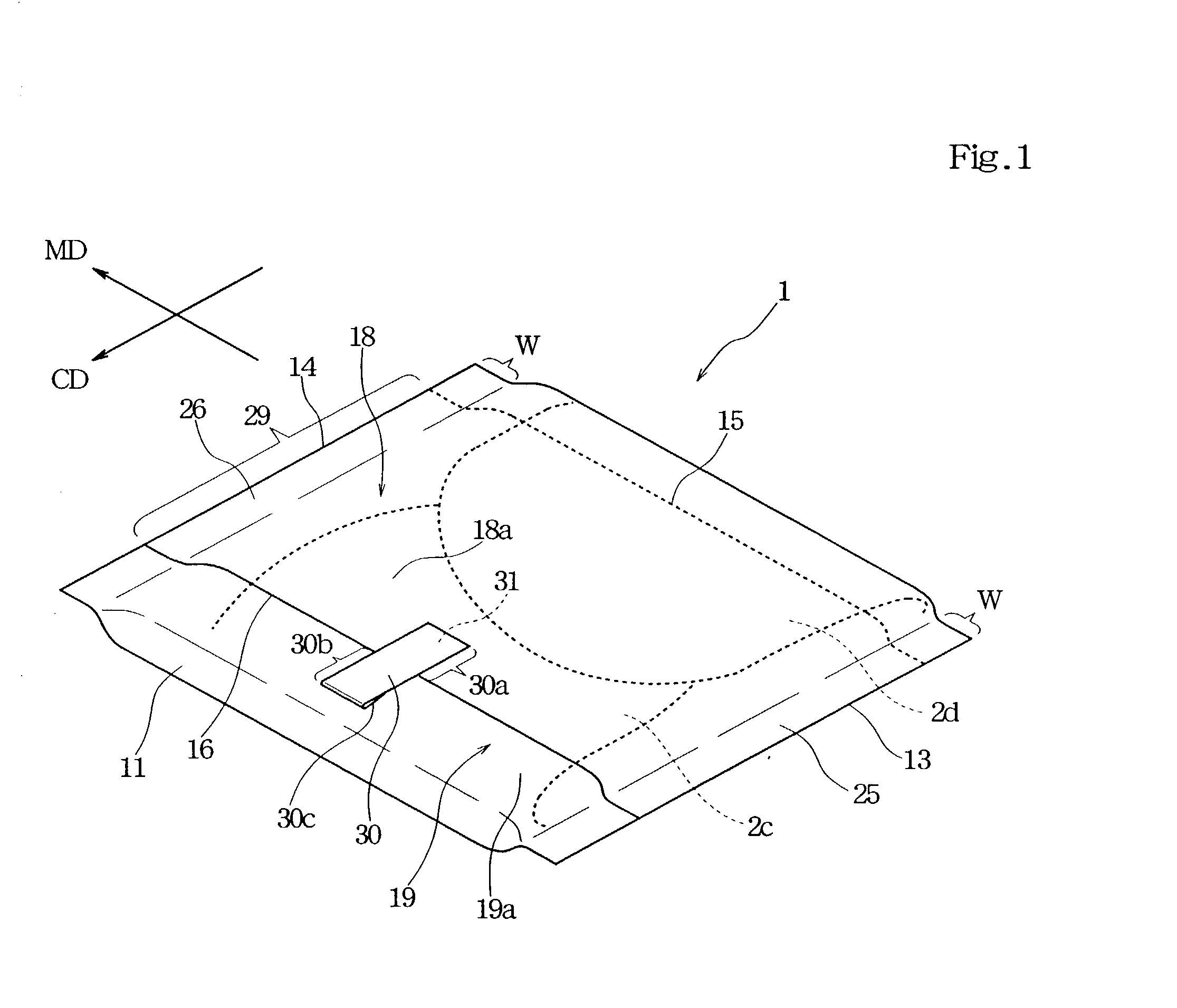

[0115] The package sheet 10 having a three-layer structure consisted of the spun-bonded non-woven fabric on the side of the first surface 11, the spun-bonded non-woven fabric on the side of the second surface 12, and a meltblown non-woven fabric sandwiched between the spun-bonded non-woven fabrics, having a basis weight of 18 g / m.sup.2, and being formed with a stripe form smoothed region 33a on the first surface 11, to which the tape 30 is bonded, as shown in FIG. 4, was used. The smoothing process was performed using a roll having a projected portion of a stripe pattern with smooth top surface, and a roll having smooth surface in entire periphery. Both rolls were heated to 115.degree. C. The packager sheet 10 is pressurized by both rolls at a pressure of 36.3 kPa.

example 2

(3) Example 2

[0116] The package sheet 10 having a three-layer structure consisted of the spun-bonded non-woven fabric on the side of the first surface 11, the spun-bonded non-woven fabric on the side of the second surface 12, and a meltblown non-woven fabric sandwiched between the spun-bonded non-woven fabrics, having a basis weight of 15 g / m.sup.2, and being formed with a stripe form smoothed region 33a is formed on the first surface 11, to which the tape 30 is bonded, as shown in FIG. 4, was used. The smoothing process was performed using a roll having a projected portion of a stripe pattern with smooth top surface, and a roll having smooth surface in entire periphery. Both rolls were heated to 105.degree. C. The packager sheet 10 is pressurized by both rolls at a pressure of 36.3 kPa.

example 3

(4) Example 3

[0117] The package sheet 10 having a three-layer structure consisted of the spun-bonded non-woven fabric on the side of the first surface 11, the spun-bonded non-woven fabric on the side of the second surface 12, and a meltblown non-woven fabric sandwiched between the spun-bonded non-woven fabrics, having a basis weight of 15 g / m.sup.2, and being formed with a stripe form smoothed region 33c on the first surface 11, to which the tape 30 is bonded, as shown in FIG. 6, was used. The smoothing process was performed using a roll having a projected portion of a stripe pattern with smooth top surface, and a roll having smooth surface in entire periphery. Both rolls were heated to 105.degree. C. The packager sheet 10 is pressurized by both rolls at a pressure of 36.3 kPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com