Punching method of new energy vehicle battery aluminum box

A technology of new energy vehicles and manufacturing methods, which is applied in the direction of batteries, battery pack components, circuits, etc., can solve the problems of difficult punching, complicated production, low efficiency, etc., and achieve the effects of improving energy density, simple method, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

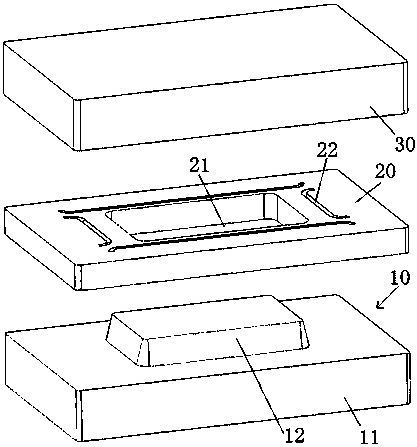

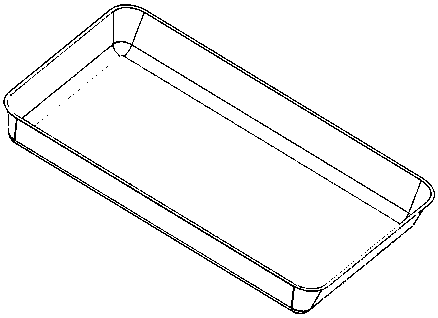

[0024] Example 1 Reference Figure 1 to Figure 4

[0025] A method for punching an aluminum box for a battery of a new energy vehicle, the steps are as follows:

[0026] 1) Material selection: Al-Fe aluminum alloy plate 1 is used as raw material, the elongation rate of the aluminum alloy plate is 38%, the plate width is 870mm, the length is 1240mm, and the thickness is 1.0mm;

[0027] 2) Film: Cover both sides of the aluminum alloy plate with a deep-drawn protective film, the viscosity of the deep-drawn protective film is 45g / 25mm, and the film thickness is 0.065mm;

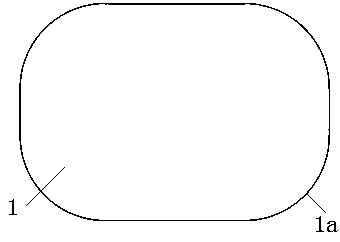

[0028] 3) Chamfering: chamfer the four corners of the coated aluminum alloy plate to 1 / 4 circle 1a respectively, and the radius of the 1 / 4 circle is 350mm;

[0029] 4) Upper die: place the rounded aluminum alloy plate on the punch surface of the stamping die, and spray stretching oil on the four sides of the aluminum alloy plate or stamping die;

[0030] 5) Stamping: Punching with the die of the stamping die f...

Embodiment 2

[0034] Example 2 Reference Figure 1 to Figure 4

[0035] A method for punching an aluminum box for a battery of a new energy vehicle, the steps are as follows:

[0036] 1) Material selection: Al-Fe aluminum alloy plate is used as raw material, the elongation rate of the aluminum alloy plate is 40%, the plate width is 860mm, the length is 1050mm, and the thickness is 0.8mm;

[0037] 2) Film: Cover both sides of the aluminum alloy plate with a deep-drawn protective film, the viscosity of the deep-drawn protective film is 30g / 25mm, and the film thickness is 0.040mm;

[0038] 3) Chamfering: chamfer the four corners of the coated aluminum alloy plate to 1 / 4 circle respectively, and the radius of the 1 / 4 circle is 290mm;

[0039] 4) Upper die: place the rounded aluminum alloy plate on the punch surface of the stamping die, and spray stretching oil on the four sides of the aluminum alloy plate or stamping die;

[0040] 5) Stamping: Punching with the die of the stamping die facing...

Embodiment 3

[0044] Example three reference Figure 1 to Figure 4

[0045] A method for punching an aluminum box for a battery of a new energy vehicle, the steps are as follows:

[0046] 1) Material selection: Al-Fe aluminum alloy plate is used as raw material, the elongation rate of the aluminum alloy plate is 42%, the plate width is 850mm, the length is 1270mm, and the thickness is 0.6mm;

[0047]2) Film: Cover both sides of the aluminum alloy plate with a deep-drawn protective film, the viscosity of the deep-drawn protective film is 60g / 25mm, and the film thickness is 0.040mm;

[0048] 3) Chamfering: chamfer the four corners of the coated aluminum alloy plate to 1 / 4 circle respectively, and the radius of the 1 / 4 circle is 270mm;

[0049] 4) Upper die: place the rounded aluminum alloy plate on the punch surface of the stamping die, and spray stretching oil on the four sides of the aluminum alloy plate or stamping die;

[0050] 5) Stamping: make the die of the stamping die face down an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Board width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com