Patents

Literature

63 results about "Ammonium hydrogen sulfite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solutions of ammonium hydrosulfide can be prepared by passing hydrogen sulfide gas through concentrated ammonia solution. According to a detailed 1895 report, hydrogen sulfide reacts with concentrated aqueous ammonia solution at room temperature to give (NH4)2S·2NH4HS.

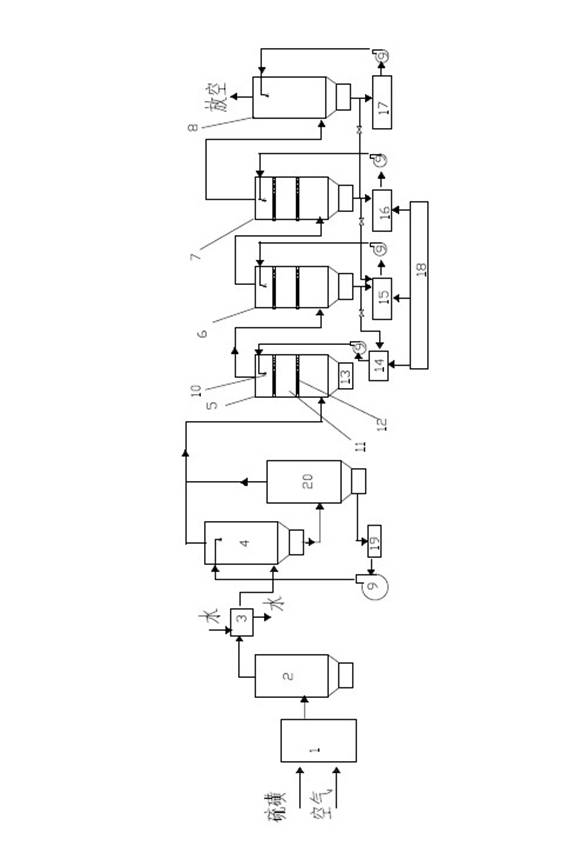

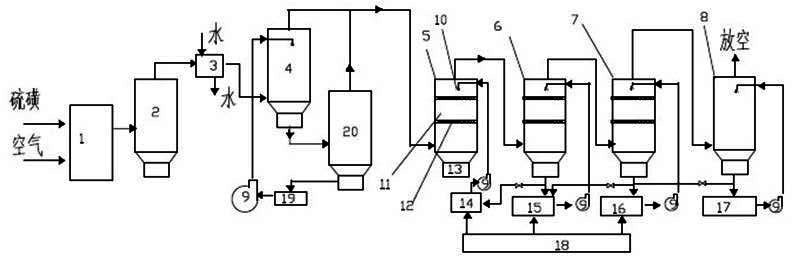

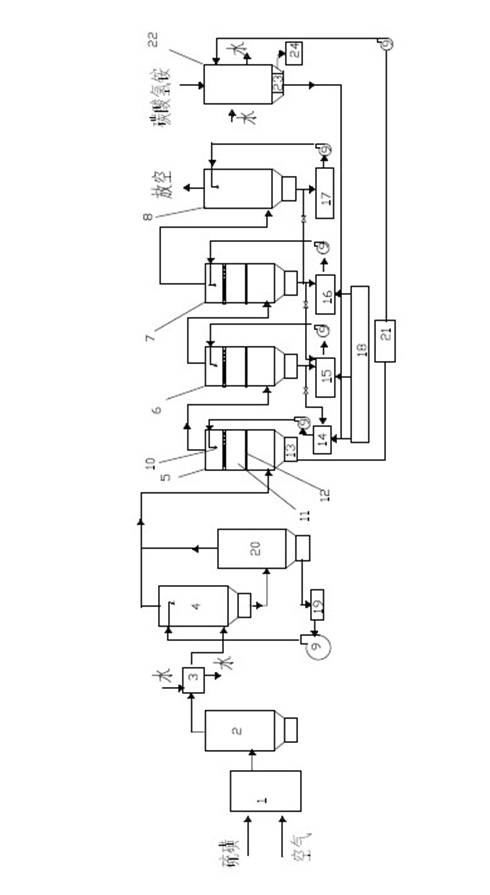

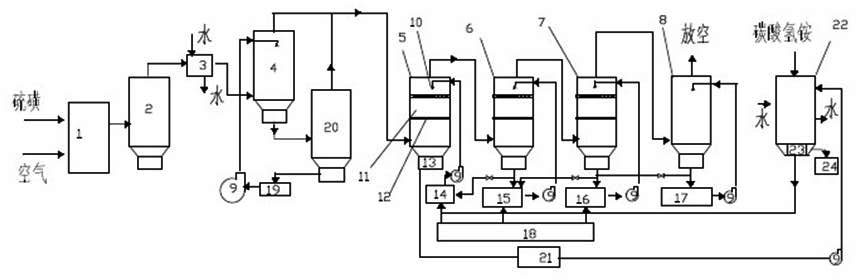

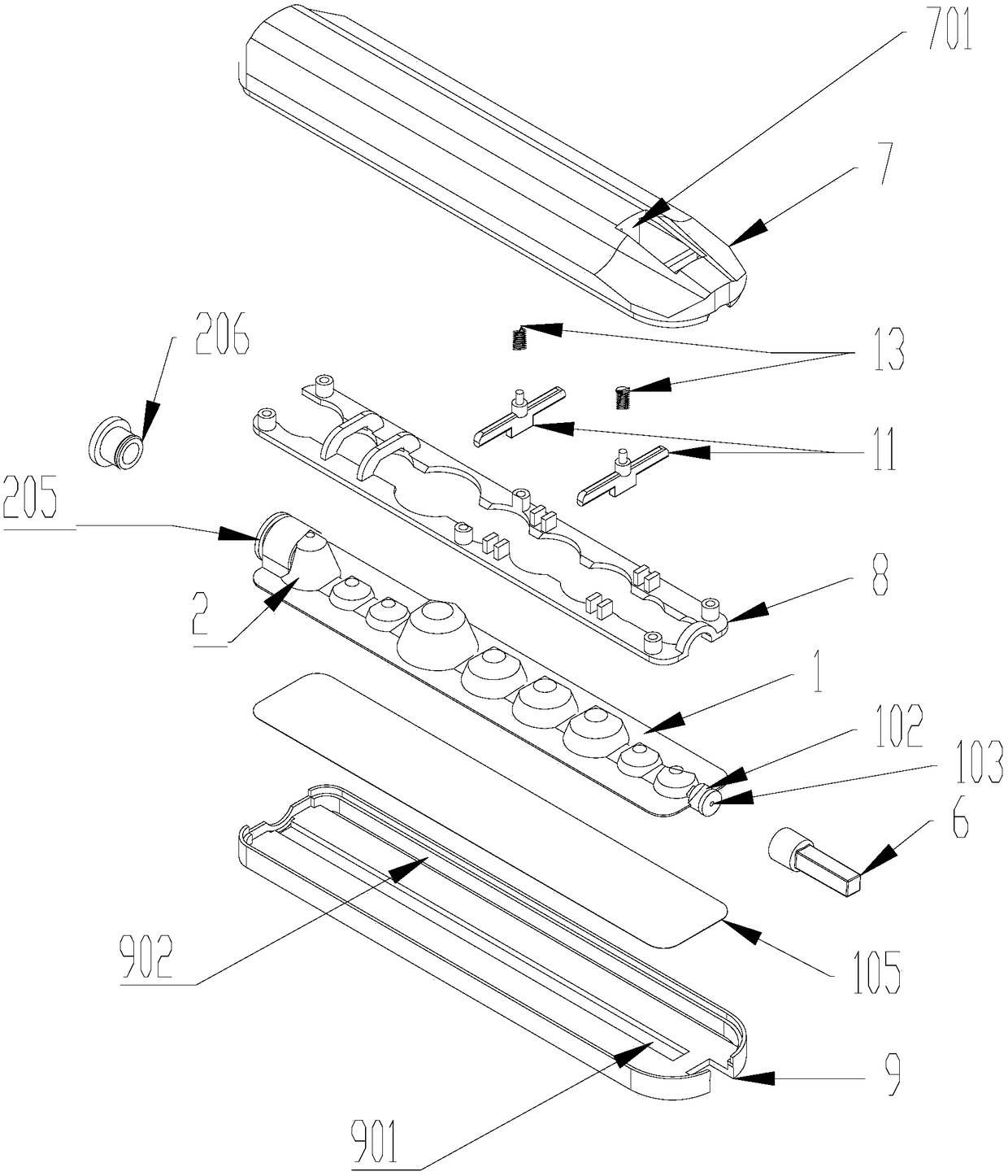

Method for ammonia method desulfurization of flue gas and high-purity ammonium hydrogen sulfite by-producing

ActiveCN102658016AHigh purityReduce concentrationUsing liquid separation agentFlue gasPhysical chemistry

Owner:水泽节(山东)环保科技有限公司

Method for ammonia method desulfurization of flue gas and high-purity solid ammonium sulfite by-producing

ActiveCN102658015AReduce concentrationEmission reductionDispersed particle separationAmmonium sulfitesDust controlPhysical chemistry

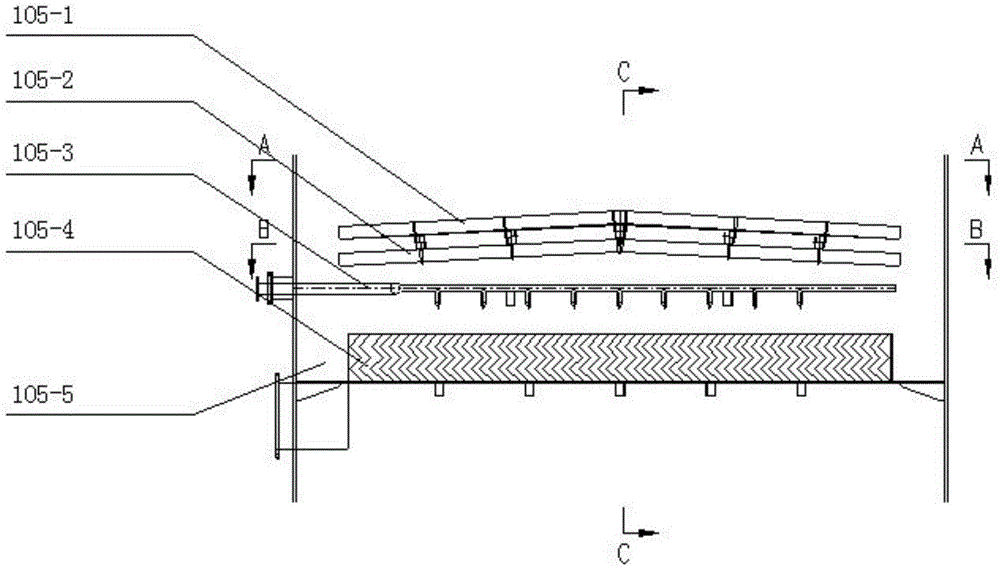

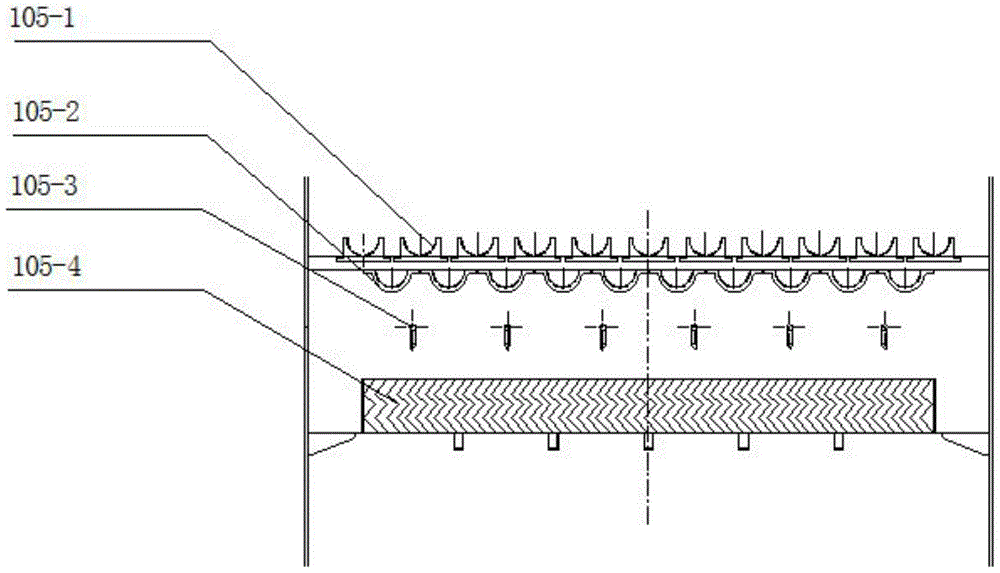

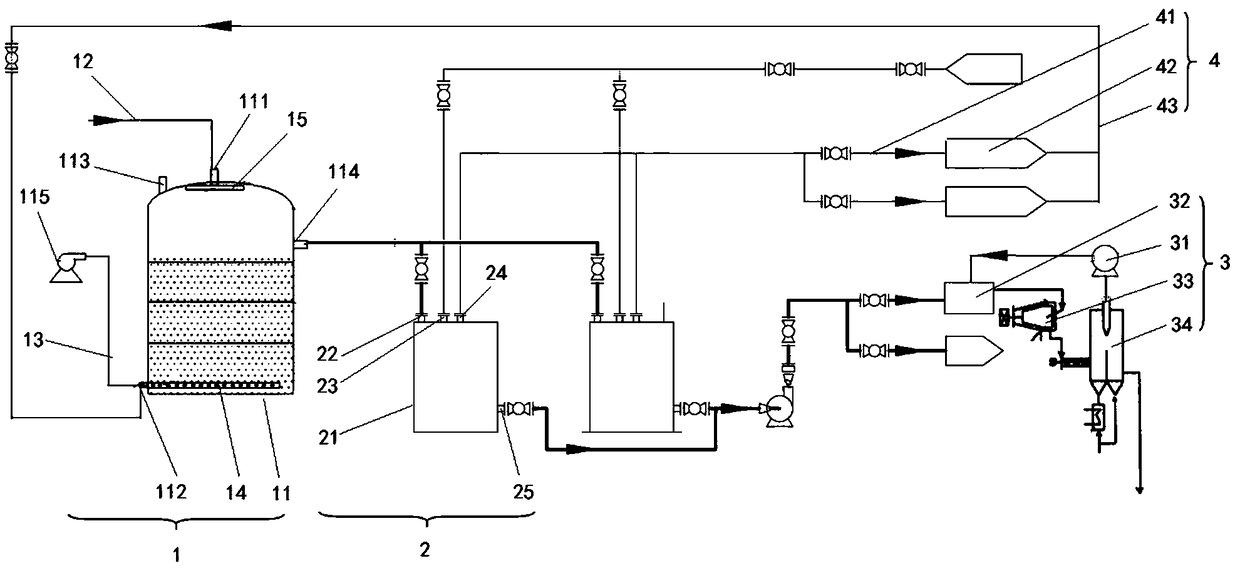

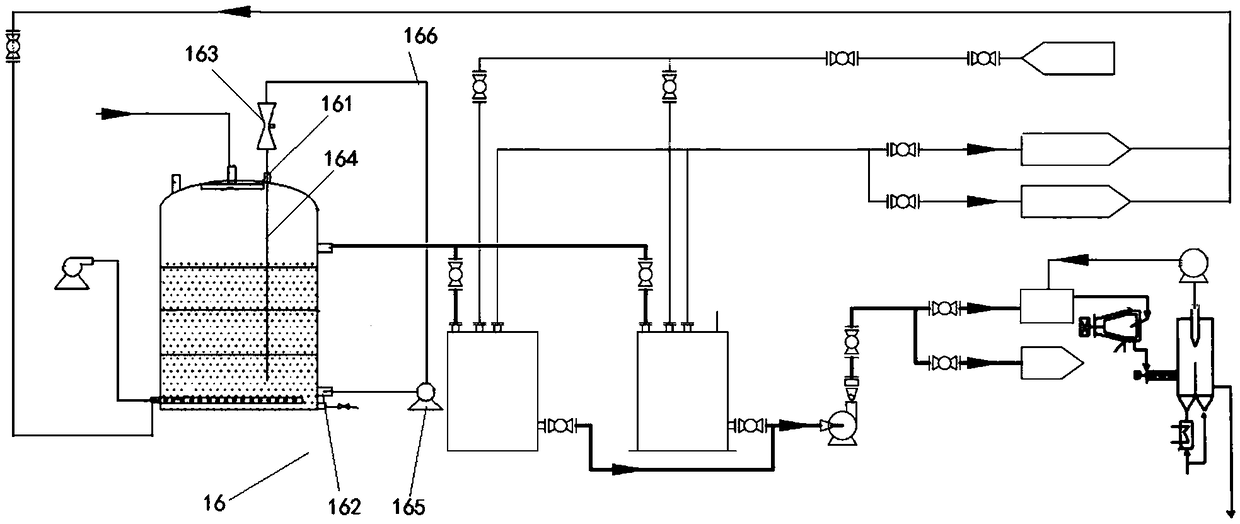

The invention discloses a method for ammonia method desulfurization of flue gas and high-purity solid ammonium sulfite by-producing. The method comprises the following steps that: solid substances rich in sulfur are firstly burnt to generate the flue gas rich in high concentration sulfur dioxide gas; the flue gas enters into a cyclone separator for dedusting, and the dedusted flue gas enters into a heat exchanger for temperature reduction; then the flue gas enters into a washing and purifying tower to be washed; the flue gas respectively enters into a primary absorption tower, a secondary absorption tower and a third absorption tower for absorption, the high concentration ammonium bisulfite solution generated through reaction is taken out from a bottom groove of the primary absorption tower and is neutralized in a neutralization tank after volume and concentration measurement, and the solid ammonium sulfite is separated by a centrifuge in the neutralization tank through cooling crystallization; and the flue gas enters into a washing tower to be discharged after washing. By the method, SO2 and other harmful acidic gas are highly purified; the utilization ratio of an ammonia absorption agent is effectively improved; high-purity solid ammonium sulfite can be obtained; and the ammonium sulfite solution has excellent special industrial use and prospect.

Owner:水泽节(山东)环保科技有限公司

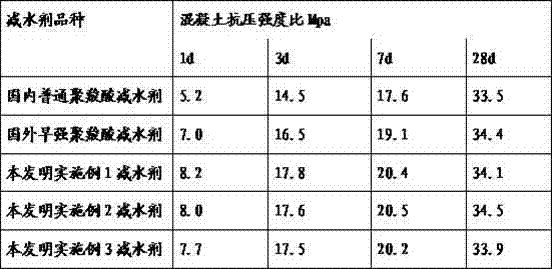

Super-high early-strength water reducing agent and processing method thereof

The invention discloses a super-high early-strength water reducing agent and a processing method thereof. The super-high early-strength water reducing agent is prepared from the following raw materials: a, allyl polyethylene glycol; b, either acrylic acid or methacrylic acid or a mixture of them; c, acrylamide; d, ammonium persulfate or potassium persulfate or a mixture of them; e, ammonium hydrogen sulfite; f, mercaptoacetic acid or mercaptoethanol or a mixture thereof, wherein the mole ratio of the adopted raw materials is as follows: a: b: c: d: e: f is 1: (3-4): (0.2-0.5): (0.06-0.1): (0.03-0.05): (0.03-0.05). The super-high early-strength water reducing agent disclosed by the invention obviously improves concrete strength, and specifically 1d strength of the water reducing agent is remarkably better than that of early-strength products in current market.

Owner:大连市铭源全科技开发有限公司

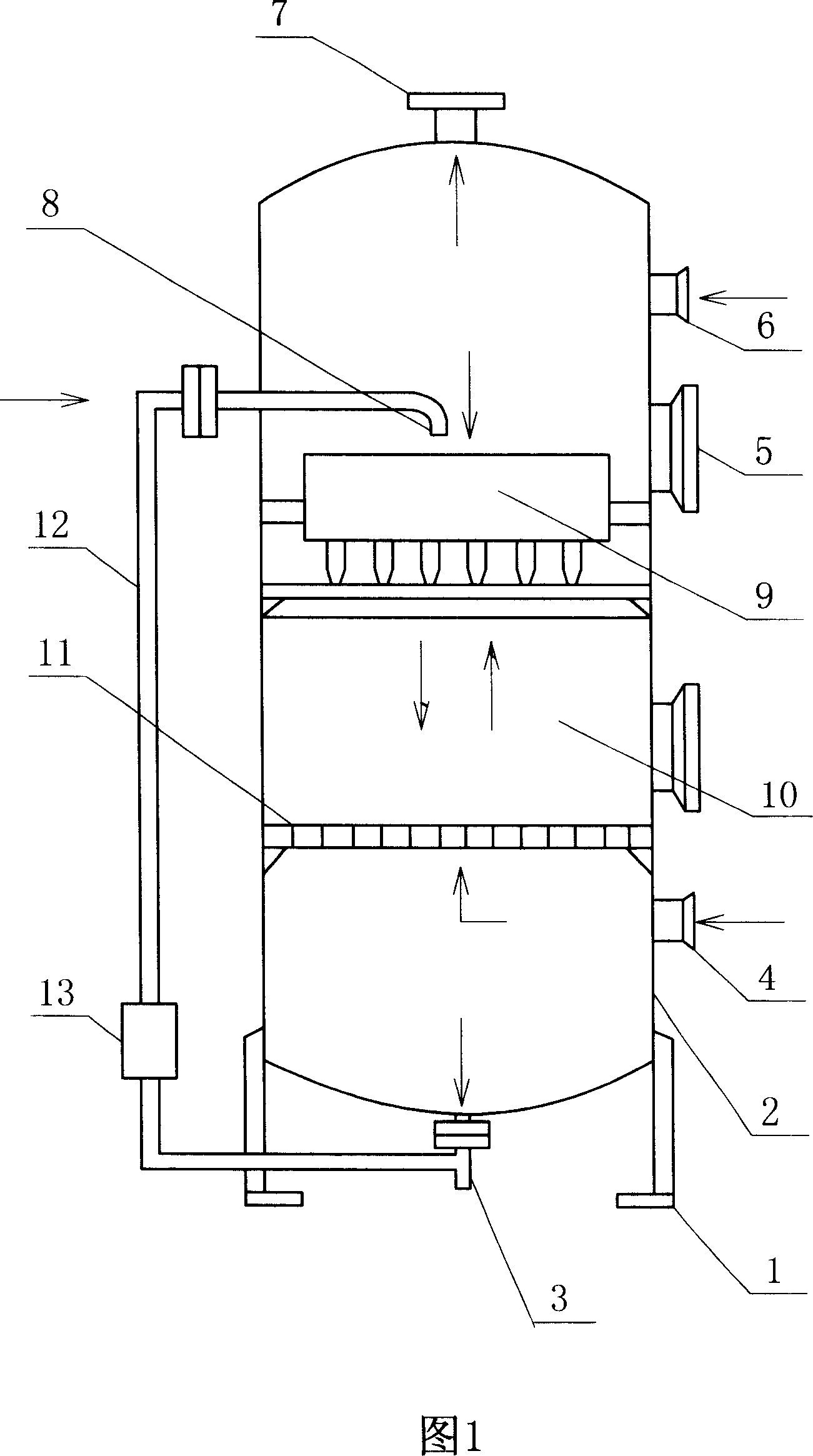

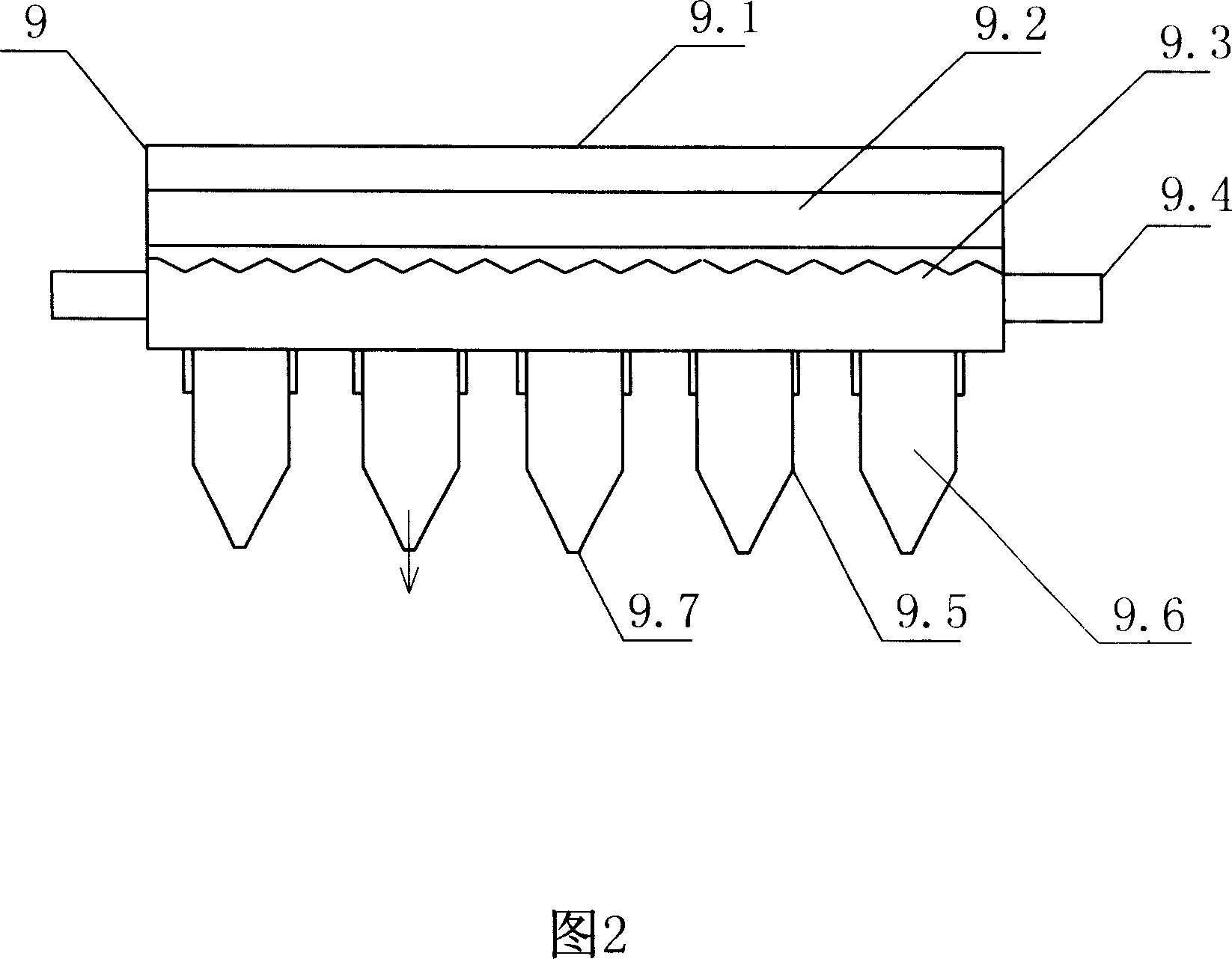

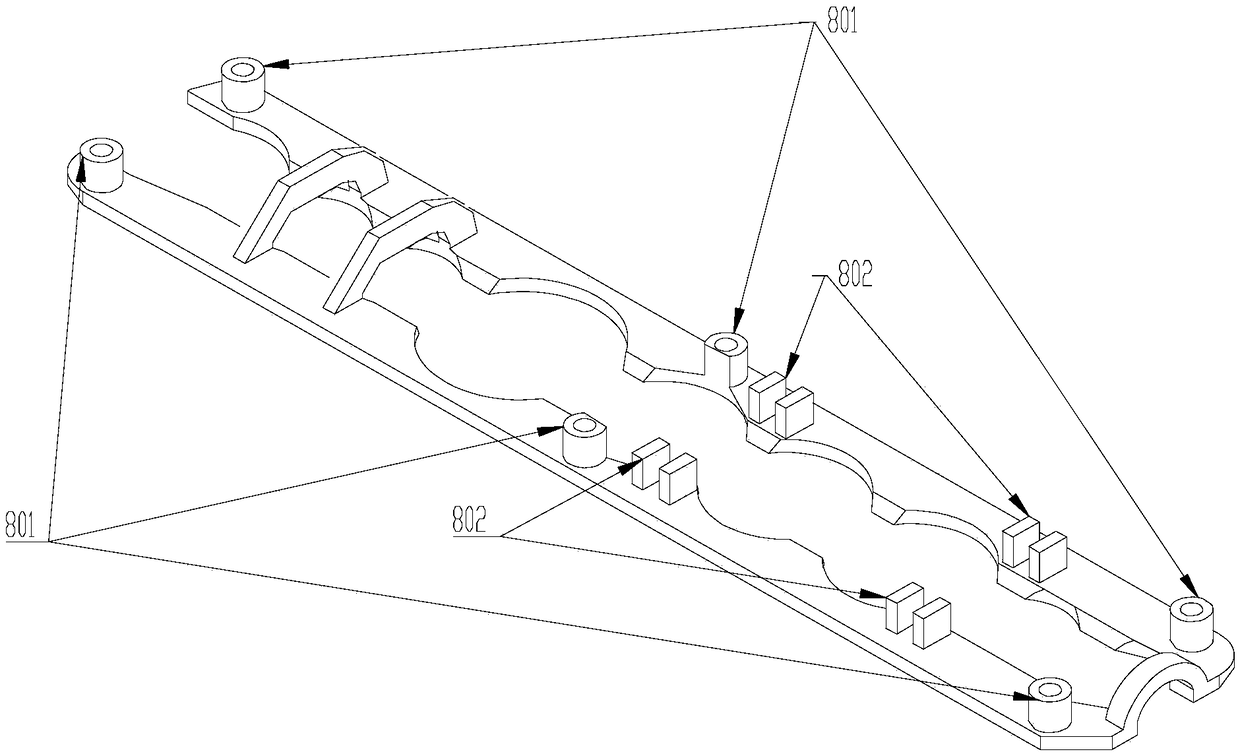

Desulfurization refining method for ammonia gas containing hydrogen sulfide and ammonia gas finisher

InactiveCN101012064AImprove refining effectReduce energy consumptionDispersed particle separationWater/sewage treatmentAmmonium hydrosulfideSewage treatment

The invention discloses a desulfurizing refining method and ammonia finisher, wherein the ammonia finisher comprises the following parts: support, liquid outlet, ammonium hydrosulfide gas inlet, human body inlet and outlet and water inlet and gas ammonia outlet, wherein the support board and distributor are set in the cavity of ammonia finisher, which forms ammonia refining area; the ammonia liquid reflux inlet is set on the top of distributor, which interconnects liquid outlet pipe through reflux pipe and reflux pump. The refining method of desulfurized ammonia comprises the following steps: 1. separating ammonia with hydrogen sulfide; 2. switching ammonia with hydrogen sulfide into ammonia finisher; 3. starting ammonia finisher; 4. operating the ammonia finisher.

Owner:葫芦岛市锦隆石化高科技有限责任公司

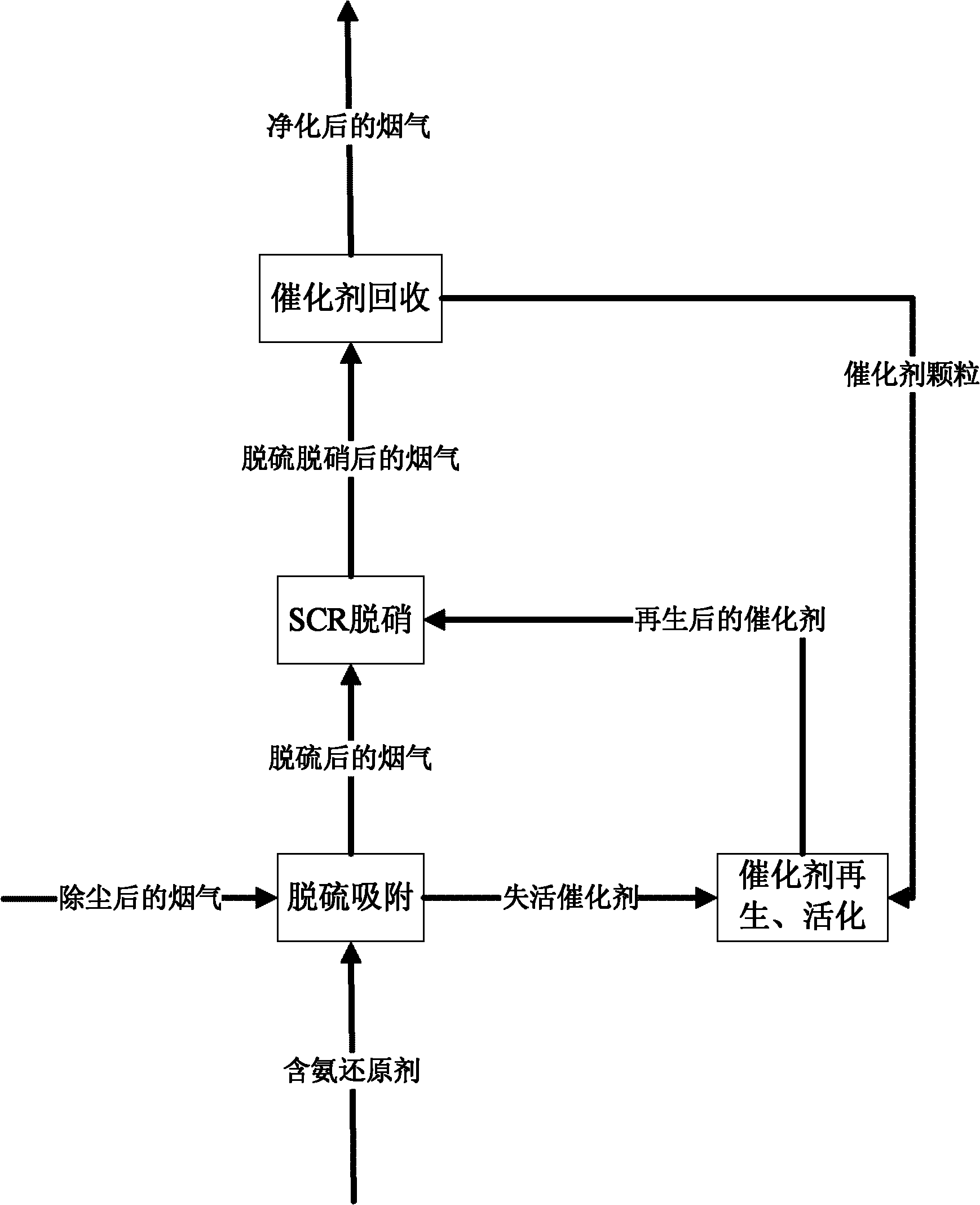

Method for desulfurating and denitrating simultaneously

ActiveCN103349900AForm secondary pollutionForm pollutionDispersed particle separationAmmonium nitrate fertilisersReducing agentNH3 compound

The invention relates to a method for desulfurating and denitrating simultaneously, and belongs to the technical field of flue gas purifying. The method comprises the following steps: spraying sulphureous nitrate flue gas at the temperature of 500 DEG C to 1500 DEG C with a reducing agent containing an NHx group, enabling NO in the flue gas to be converted into N2, then using desulfuration absorption liquid containing ammonium sulfite and ammonium hydrogen sulfite to spray, enabling the residual NOX in the flue gas to be reduced into N2, and absorbing SO2 gas in the flue gas; discharging out standard flue gas absorbed with NOX and SO2 , and after being supplied with ammonia water solution, the desulfuration absorption liquid absorbed with NOX and SO2 is used for circularly spraying the flue gas sprayed by the reducing agent containing the NHx group. The method has the benefits that the technology is simple and convenient; the desulfurating and denitrating effect is obvious; the running cost is low; by-products with higher economic values can be produced; the effect of resource recycling is achieved.

Owner:ASIA PACIFIC ENVIRONMENTAL CORP

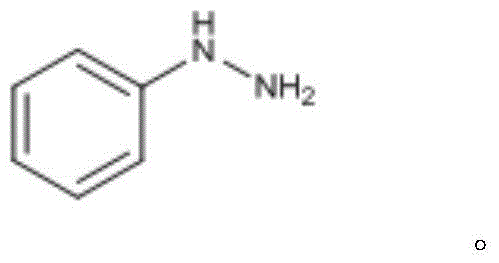

Synthetic method of phenylhydrazine

ActiveCN104610093AReduce water consumptionHigh recycling valueHydrazine preparationDistillationAniline

The invention discloses a synthetic method of phenylhydrazine. The synthetic method comprises the following steps: adding dilute sulfuric acid into aniline, dropwise adding ammonium nitrite at 0-5 DEG C, and then performing thermal reaction for 4-6 minutes; then cooling to a temperature between -5 and -10 DEG C, adding a solid reducing agent, and stirring violently; when the temperature of the reaction system naturally rises to be more than 40 DEG C, adding dilute sulfuric acid to adjust the pH value to be 2-4, and heating to 70-100 DEG C to react for 4-6 hours; and separating the obtained reaction product to obtain phenylhydrazine. According to the synthetic process of phenylhydrazine, disclosed by the invention, aniline is used as a raw material, dilute sulfuric acid is used as salt forming and acidifying reagents, ammonium nitrite is used as a diazotization reagent, ammonium sulfite and / or ammonium hydrogen sulfite is used as the reducing agent, ammonia gas is used for neutralizing a reaction solution, phenylhydrazine is finally obtained by virtue of extraction and distillation, and a byproduct salt is single ammonium sulfate.

Owner:江苏艾科维科技有限公司

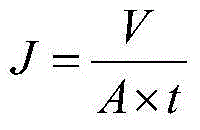

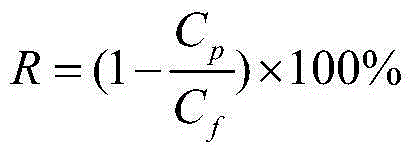

Preparation method for dried reverse osmosis composite membrane

ActiveCN105148742ASolve the problem of separation performance degradationReverse osmosisReverse osmosisPotassium

The invention relates to a preparation method for a dried reverse osmosis composite membrane. The preparation method comprises the following steps: soaking a conventional reverse osmosis composite membrane in a protector-containing aqueous solution, wherein the soaking temperature is 10-50 DEG C and the soaking time is 1-10 minutes; and then carrying out thermal treatment for 8-12 minutes in an oven at 80-100 DEG C, wherein the protector is one or a mixture of more of sodium hydrogen sulfite, potassium hydrogen sulfite, ammonium hydrogen sulfite, formic acid, oxalic acid, citric acid, dipotassium glycyrrhizate, butylated hydroxyanisole, butylated hydroxytoluene, propylgallate, tert-butylhydroquinone, tea polyphenol, 3,4,5,7-tetrahydroxy flavone and a glycyrrhisoflavone solution. The preparation method provided by the invention not only can be used for realizing dry state storage of the reverse osmosis composite membrane, but also can effectively solve the problem that the dried reverse osmosis composite membrane is attenuated in performance in a long-term storage process.

Owner:HANGZHOU FANGRAN MEMBRANE TECH

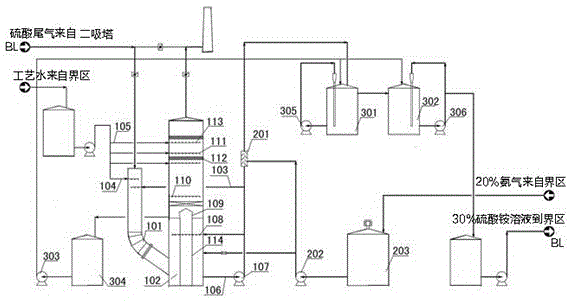

Sulfuric acid tail gas desulphurization device and method

InactiveCN104998530AImprove desulfurization efficiencyIncrease contact areaChemical industryDispersed particle separationTowerCirculating pump

The invention relates to a sulfuric acid tail gas desulphurization device and method. A multi-layer spraying, cleaning and defogging device and anti-blocking design are adopted in a desulphurization tower, and the three functions of desulphurization, cleaning and defogging are integrated by the tower. The bottom of the desulphurization tower is connected into a liquid outlet pipe and a circulating pump. The circulating pump is connected to a mixing device through a pipe. The mixing device is connected with an ammonia water pump through a pipe and connected into an ammonia water tank. Circulating solutions in the tower are ammonium sulfite and ammonium hydrogen sulfite. The higher desulphurization efficiency can be reached. The mixing device is connected into a first-level oxidation tank through a pipe and connected into a second-level oxidation tank. Secondary hydrogen peroxide oxidation outside the desulphurization tower is conducted, an ammonium sulfite solution and hydrogen peroxide fully react with each other through stirring of the air, the oxidation rate of the ammonium sulfite can reach over 98%, the quality of a by-product ammonium sulfate solution is guaranteed reliably, absorption, adjustment and oxidation are conducted on sulfuric acid tail gas, ammonium sulfate is generated, operating devices are fewer, and low power consumption and the energy-saving effect are achieved.

Owner:武汉宇青环保科技有限公司

Kit for detecting PAX1 (Paired Box 1) gene methylation in cervical cancer

ActiveCN108753968AAvoid cross contaminationFacilitate the amplification reactionBioreactor/fermenter combinationsBiological substance pretreatmentsHistone methylationHydroquinone Compound

The invention provides a kit for detecting PAX1 (Paired Box 1) gene methylation in cervical cancer. The kit comprises a splitting reagent and a binding fortifier, wherein the splitting reagent comprises a splitting modification solution which is prepared from ammonium hydrogen sulfite, ammonium sulfite, guanidine hydrochloride, sodium hydroxide and hydroquinone; the binding fortifier is prepared from isopropanol and sodium chloride. According to the kit provided by the invention, extraction and amplification detection of nucleic acid are integrated under a totally enclosed environment, high efficiency and simpleness are realized, and a result is accurate.

Owner:GUANGZHOU HEAS BIOTECH CO LTD

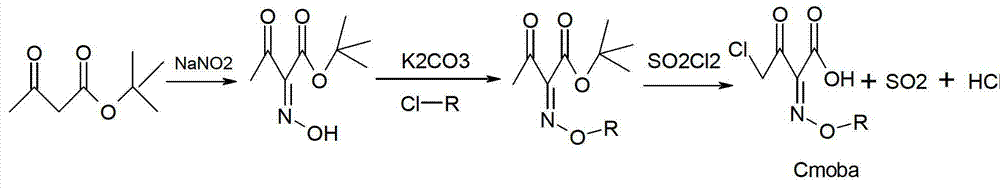

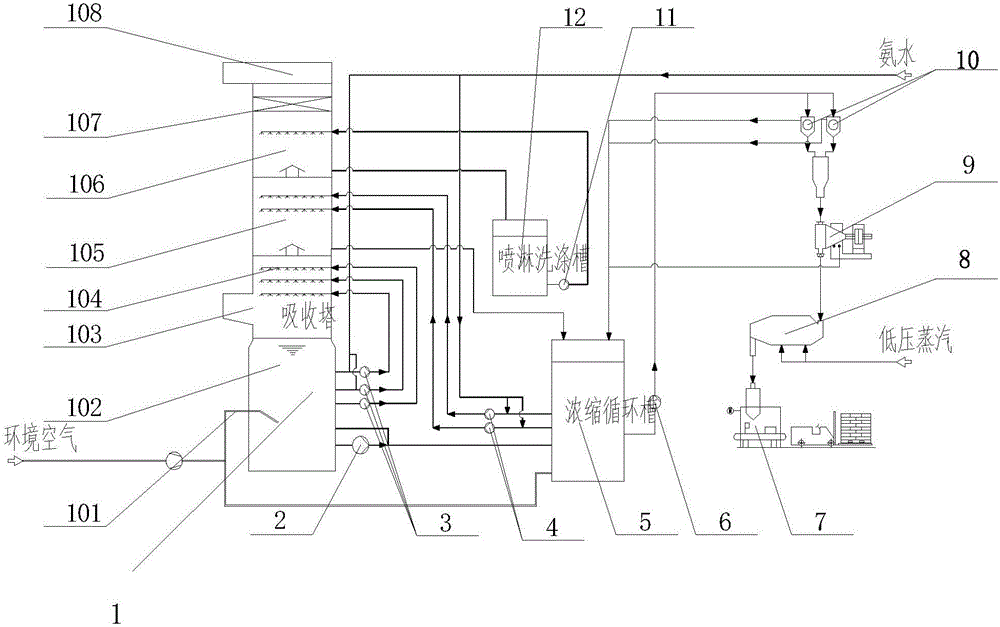

Method for recycling tail gas of sulfonyl chloride chlorination in Cmoba synthesis

InactiveCN103111181AEmission reductionOptimize the marketDispersed particle separationSulfonyl chlorideAlkylation

The invention relates to a method for recycling tail gas of sulfonyl chloride chlorination in Cmoba synthesis, and belongs to the tail gas absorption and treatment in the chemical field. The method is characterized by comprising the following steps: gaining sulfur dioxide and hydrogen chloride which are generated in the reaction; carrying out two-stage absorption on the hydrogen chloride by water to obtain the hydrochloric acid containing little sulfur dioxide, wherein the hydrochloric acid containing little sulfur dioxide is utilized in the alkylation step of the Cmoba preparation process; carrying out two-stage absorption on the rest sulfur dioxide through ammonia water to prepare the mixed solution of ammonium hydrogen sulfite and ammonium sulfite; and concentrating the obtained ammonium salt solution which is directly used as a reducing agent. By adopting the method, the gases, namely, hydrogen chloride and the sulfur dioxide, produced in the Cmoba chlorination process can be effectively recycled, so that the emission of harmful tail gas can be reduced, and the volume of drained wastewater in the Cmoba alkylation process is also reduced; simultaneously, the mixed solution of the byproducts, namely, ammonium hydrogen sulfite and ammonium sulfite, is used as the reducing agent which is in a good market prospect; and the method is simple in equipment, mild in technological condition and convenient to operate.

Owner:SHANDONG JINCHENG KERUI CHEMICAL CO LTD

Synthetic process of 4-ampyrone product

InactiveCN106699664AThe synthesis process is simpleHigh yieldOrganic chemistryNitrosoReaction temperature

The invention provides a synthetic process of a 4-ampyrone product, which comprises the following steps of: preparing antipyrine and sulfuric acid with concentration of 40 to 60% into solution; enabling the solution and sodium nitrite solution to simultaneously flow into a nitrosation reactor, controlling flow rates of the solution and the sodium nitrite solution, and controlling a reaction temperature to be 45 to 50 DEG C; performing a reaction with stirring; testing a reaction endpoint by iodine powder and starch test paper to regulate a water flow rate; enabling nitroso antipyrine generated by nitrosation to immediately flow into a reducing pot to react with a reducing agent ammonium hydrogen sulfite prepared in the pot and aqueous solution of ammonium sulfite; carrying out sampling and measuring a pH value and a reduction degree; heating to a temperature of 90 to 100 DEG C; after hydrolysis, cooling to a temperature of 80 to 85 DEG C; neutralizing to pH of 7 to 7.5 by liquid ammonia; carrying out standing and layering. The process provided by the invention is simple, convenient to operate and high in yield.

Owner:湖州吴兴道场城乡建设发展有限公司

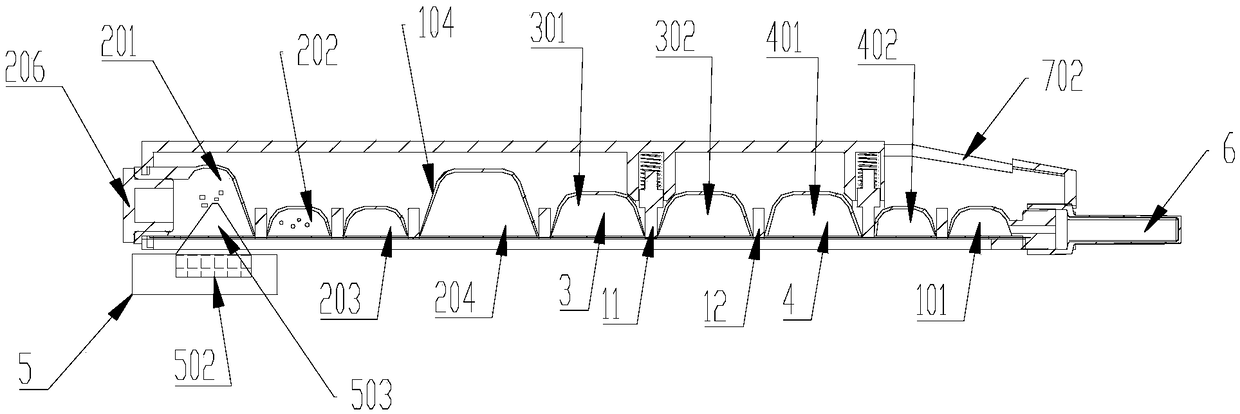

Technology for preparing ammonium sulfate by high-efficiency ammonia desulphurization and crystallization

ActiveCN103553078AHigh yieldImprove efficiencyDispersed particle separationAmmonia compoundsProcess engineeringSulfurous acid

The invention discloses a technology for preparing ammonium sulfate by high-efficiency ammonia desulphurization and crystallization, belonging to the field of a flue gas desulfurization and dust removal technology. The technology comprises the working procedures of desulphurization, oxidization and concentration and comprises the steps of firstly, filling flue gas and ammonia water into a desulphurization section of a desulfurizing tower, and feeding slurry which is generated after reaction and desulphurization and contains ammonium hydrogen sulfite and ammonium sulfite into a regeneration storage tank; filling the ammonia water into the regeneration storage tank to have reaction with the ammonium hydrogen sulfite to generate ammonium sulfite, then feeding the ammonium sulfite solution into an oxidization section of the desulfurizing tower, and feeding slurry which is generated by oxidization reaction between the ammonium sulfite and the flue gas and contains ammonium sulfate into a concentration storage tank; conveying the ammonium sulfate solution from the concentration storage tank into a cooling section of the desulfurizing tower, and enabling the ammonium sulfate solution to come into contact with the flue gas to exchange heat; concentrating the ammonium sulfate solution and then feeding the concentrated ammonium sulfate solution in a crystallization storage tank; conveying the product into a separator, and carrying out solid-liquid separation. The technology utilizes the characteristic that the flue gas is high in oxygen content, so that the ammonium sulfite oxidization efficiency is high, the crystallization velocity of the ammonium sulfate is improved, the equipment input and the production energy consumption are effectively reduced, the potential safety hazard of production is reduced, and the economic benefit is remarkable.

Owner:YUNNAN YONGXIN ALUMINUM

Process for preparing hydrogen sulfide

The invention discloses a process for preparing hydrogen sulfide through the reaction between sulfuric-acid-containing exhausted liquid (by product of the production process for preparing chemical product and intermediate product by means of chemical reactions) and barium sulphide water soluble liquid phase (prepared from barium sulphide calcined member through water leaching), the produced hydrogen sulfide can be further used in preparing other chemical products, such as sodium hydroxide, sodium hydrogen sulfide, ammonium sulfide, ammonium hydrosulfide, sulfourea, methyl hydrosulfide, ethyl mercaptan and dimethyl sulfur ether.

Owner:唐培堃

Synthesis process of racemic phenyl ethanesulfonic acid

InactiveCN102766076ARaw materials are cheap and easy to getMild reaction conditionsOrganic chemistryOrganic compound preparationThioureaImpurity

The invention relates to a synthesis process of racemic phenyl ethanesulfonic acid. The conventional main production process is that 1-bromobenzene ethane is taken as a raw material to react with anhydrous ammonium hydrogen sulfite so as to generate the racemic phenyl ethanesulfonic acid, but the price of the 1-bromobenzene ethane needed by the process is high, the reaction yield is low and three wastes are multiple. The synthesis process disclosed by the invention is characterized by comprising the following steps of: reacting 1mol of styrene, 1mol of HCl water solution and 1mol of thiourea for 3-8 hours under an effect of a phase transfer catalyst quaternary ammonium salt; carrying out neutralizing by utilizing 1mol of inorganic alkali water solution to enable pH to be 5-8, reducing the temperature and separating liquid; oxidizing an organic phase in an organic acid by utilizing 2mol of hydrogen peroxide; after the oxidization, evaporating and removing the organic acid and impurities to obtain a racemic phenyl ethanesulfonic acid solution; and adding methanol to remove the salt and evaporating to obtain the racemic phenyl ethanesulfonic acid. The synthesis process disclosed by the invention selects the cheap styrene and thiourea as starting materials; sulfydryl is firstly introduced and then a target product (racemic phenyl ethanesulfonic acid) is prepared by the oxidization; and the synthesis process has the advantages of being cheap and easily-obtained in raw materials, moderate in reaction conditions, easy to control and high in yield.

Owner:ZHEJIANG YUNTAO BIOTECH

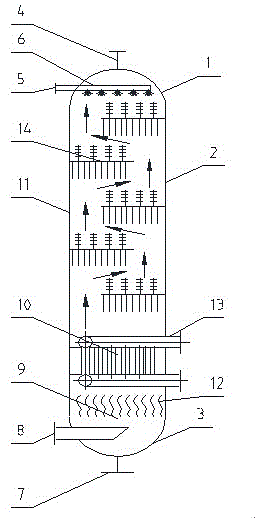

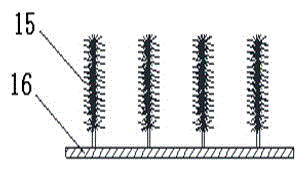

Graded tower internal crystallization ammonia-process desulfurization method

InactiveCN105771591AImprove absorption efficiencyBest absorption environmentGas treatmentDispersed particle separationProcess systemsThiamine

The invention discloses a graded tower internal crystallization ammonia-process desulfurization method comprising the following steps: step one, flue gas enters a lower-stage adsorption section of a desulfurization absorption tower from a flue gas inlet, and is subjected to a reaction with an ammonia water solution and an ammonium sulfite solution; step two, the flue gas obtained after the step one continues to flow to the upper part of the desulfurization absorption tower, and enters an upper-stage absorption section; step three, an ammonium hydrogen sulfite solution generated in the step one is subjected to oxidation aeration at the bottom of the desulfurization tower; step four, an ammonium sulfate solution generated from oxidation is sent into a back-end process system from a hydrocyclone feeding plump; step five, a spray washing liquid in the step 2 is supplied to a spray washing layer from a spray washing tank through a circulation spray washing pump; step six, an ammonium sulfate solution accumulated in a concentration circulating tank in the step three flows back to a cooling concentration section of the desulfurization absorption tower through a pipeline; and step seven, thiamine slurry is sent to a thiamine hydrocyclone by the hydrocyclone feeding pump and is treated. The technical problems that a conventional ammonia-process desulphurization technology has bad flue gas purification effect are solved.

Owner:XIAN AEROSPACE SOURCE POWER ENG CO LTD

Organic sewage treatment agent

InactiveCN105174488AImprove efficiencyQuick removalBiological water/sewage treatmentCelluloseChemical oxygen demand

The invention discloses an organic sewage treatment agent and belongs to the technical field of sewage treatment agent preparation. The organic sewage treatment agent comprises the following raw materials in parts by weight: 20 to 40 parts of whole-cell lipase, 10 to 20 parts of cellulose, 10 to 20 parts of fatty alcohol-polyoxyethylene ether, 8 to 16 parts of sec-Nonylphenol Ethoxylates, 6 to 12 parts of epoxypropane, 10 to 16 parts of aluminum sulfate, 8 to 14 parts of alums, 8 to 16 parts of alkyl-sodium proparesulfonic acid, 4 to 10 parts of hexadecyltrimethyl ammonium nitrate, 6 to 20 parts of dimethyl-bi-dodecyl ammonium nitrate, 2 to 4 parts of ammonium hydrogen sulfite and 2 to 4 parts of hydrazine. The organic sewage treatment agent disclosed by the invention is capable of rapidly removing SS (suspended solid), grease and COD (chemical oxygen demand); the organic sewage treatment agent is high in efficiency and has no corrosivity; the removal rate reaches more than 9 percent, and secondary pollution cannot be caused to sewage in later stage.

Owner:石东秀

Application method of fine desulfurization in sulfuric acid exhaust absorption

The invention discloses an application method of fine desulfurization in sulfuric acid exhaust absorption, and relates to a technical scheme of the application of fine desulfurization in sulfuric acid exhaust absorption, in particular to a method for discharging SO2 exhaust. The method comprises the following steps of: A, introducing sulfur-containing exhaust into an absorption tower; and B, spraying ammonium sulfite-ammonium hydrogen sulfite solution serving as a fine desulfurization solution with the pH value of 5.6 to 6.1 from the top of the tower to absorb SO2 and SO3 in the sulfur-containing exhaust, and regulating the gas-liquid ratio to be (350-370): 1, wherein according to the concentration of aqueous ammonia in step B, the absorption mother solution refluxes to a mother solution circulating tank from the bottom of the absorption tower, and 10.3 to 10.6 mass percent of diluted aqueous ammonia is added, so that the ratio of (NH4)2SO3 to NH4HSO3 in the absorption solution is unchanged in an optimal range of the ammonium sulfite-ammonium hydrogen sulfite solution serving as the fine desulfurization solution; and the temperature of the mother solution in step B is between 25 and 30 DEG C. After the sulfur-containing exhaust is treated, the conversion rate of a sulfur acid device is more than or equal to 99.5 percent, and 60mg / Nm<3> of SO2 exhaust is discharged; and by substituting the expensive imported accelerant for the cheap domestic accelerant, the national emission standard can also be achieved, and the cost is reduced.

Owner:云南云天化云峰化工有限公司

Treatment method and device of desulfurization tail gas

InactiveCN109499289AIncrease productionIncrease profitDispersed particle separationAmmonium salt fertilisersWater vaporAir compressor

The invention provides a treatment method and device of desulfurization tail gas. The method comprises the following steps of: taking ammonia as a desulfurization agent; enabling the ammonia to be ingas-liquid sufficient contact with sulfur-containing flue gas in a sulfuric acid tail gas absorption tower and reacting to generate a mixed solution of ammonium sulfite, ammonium bisulfite and ammonium sulfate; carrying out oxidization reaction on the generated ammonium sulfite solution, the ammonium bisulfite and concentrated sulfuric acid in a reaction kettle to obtain an ammonium sulfate solution; meanwhile, releasing sulfur dioxide gas; carrying out post-treatment on the ammonium sulfate solution to obtain an ammonium sulfate finished product; separating sulfur dioxide and water steam, which are released through reaction, and conveying the water steam into the sulfuric acid tail gas absorption tower through a reflux pipe and a sulfur-containing flue gas feeding opening. According to the method provided by the invention, a process of converting the ammonium sulfite into the ammonium sulfate can be finished by directly adopting a concentrated sulfuric acid one-step conversion method;the method is simple to operate and the conversion rate of the ammonium sulfite can reach 100 percent; the energy consumption of an air compressor can be saved; meanwhile, the sulfur dioxide in tailgas is recycled into an acid production system, so that the yield of the sulfuric acid and the utilization rate of sulfur are improved.

Owner:襄阳泽东化工集团股份有限公司

Anti-corrosion paint on hardware mold

InactiveCN106280896APreparation with few ingredientsSimple preparation processAnti-corrosive paintsEpoxy resin coatingsPolyvinyl butyralPolyvinyl alcohol

The invention relates to anti-corrosion paint on a hardware mold. The anti-corrosion paint is prepared from the following ingredients in parts by weight: 45 to 59 parts of resin, 12 to 14 parts of ammonium sulfate, 5 to 9 parts of ammonium hydrogen sulfite, 3 to 6 parts of polyvinyl alcohol, 4 to 9 parts of polyvinyl butyral, 2 to 5 parts of titanium dioxide, 6 to 10 parts of quartz powder, 2 to 7 parts of iron powder, 5 to 7 parts of talcum powder, 1 to 4 parts of barium sulfate, 1 to 3 parts of anti-settling agents, 0.6 to 1.8 parts of defoaming agents, 1.2 to 1.6 parts of corrosion removers and 15 to 17 parts of water. The anti-corrosion paint prepared in the mode has the advantages that the preparation ingredients are few; the preparation process is simple; the anti-corrosion performance is good; after the anti-corrosion paint obtained through preparation is coated onto the surface of the hardware mold, good anti-corrosion performance is realized; the hardware tool cannot generate a corroded phenomenon under the long-time casting condition by cooling liquid; the quality is good; the performance is stable.

Owner:岳西县日胜商贸有限公司

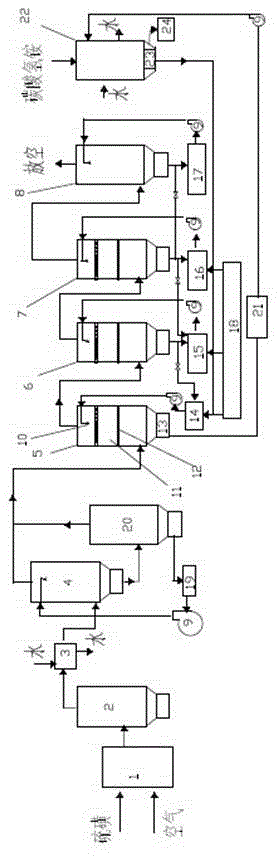

A method for flue gas ammonia desulfurization and by-product high-purity solid ammonium sulfite

ActiveCN102658015BReduce concentrationEmission reductionDispersed particle separationAmmonium sulfitesDust controlPhysical chemistry

The invention discloses a method for flue gas ammonia desulfurization and high-purity solid ammonium sulfite as a by-product. Firstly, sulfur-rich solid matter is burned to generate flue gas rich in high-concentration sulfur dioxide gas; the flue gas enters cyclone separation The flue gas after dust removal enters the heat exchanger to cool down; then the flue gas enters the washing and purification tower for washing; the flue gas enters the first-level absorption tower, the second-level absorption tower, and the third-level absorption tower for absorption, and the reaction generated The high-concentration ammonium bisulfite solution is taken out from the bottom tank of the primary absorption tower, and then neutralized in the neutralization tank after measuring the volume and concentration. After cooling and crystallizing, the solid sulfurous acid is separated by the centrifuge in the neutralization tank Ammonium; then the flue gas enters the water washing tower and is washed and discharged. The invention has the characteristics of highly purifying SO2 and other harmful acid gases, effectively improving the utilization rate of ammonia absorbent, etc., and can obtain high-purity solid ammonium sulfite, and has good special industrial applications and prospects.

Owner:水泽节(山东)环保科技有限公司

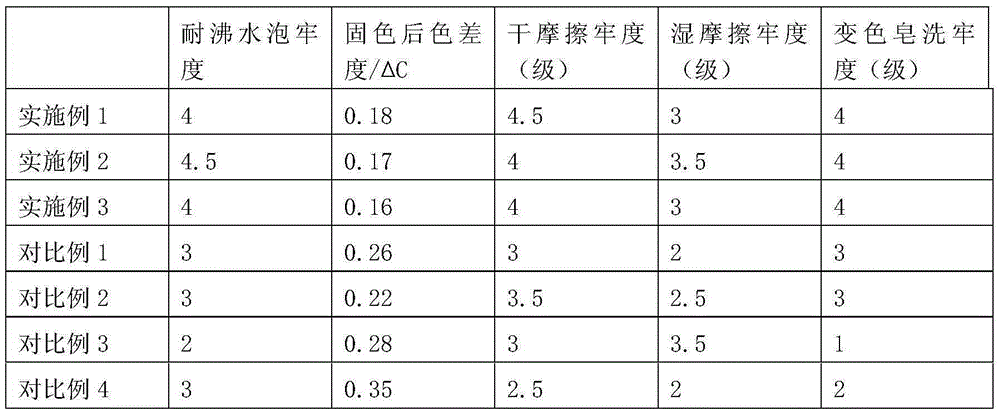

Novel environment-friendly formaldehyde-free dye-fixing agent and preparation method thereof

InactiveCN105421118AImprove protectionKeep healthyDyeing processPolyethylene glycolHydroxypropyltrimethyl ammonium chloride chitosan

The invention discloses a novel environment-friendly formaldehyde-free dye-fixing agent which is prepared from crylic acid, ammonium hydrogen sulfite, epoxy chloropropane, benzyl triethyl ammonium chloride, hydroxypropyltrimethyl ammonium chloride chitosan, polyethylene polyamine resin condensation polymer, peroxysulphate, fatty acid polyethylene glycol ester, triallylamine, methacrylic acid beta-butyl hydroxyl and deionized water. The environment-friendly formaldehyde-free dye-fixing agent and a preparation method thereof are used for improving the colour fixation effect of a fabric on a dyestuff, the colour fastness of the fabric is improved, and good washing resistance and fastness are achieved.

Owner:湖州市千金丝织厂(普通合伙)

Household appliance anticorrosive coating and preparation method thereof

InactiveCN105820672AReduce formaldehyde contentImprove cold resistanceFireproof paintsRubber derivative coatingsSmoked PlumSodium hydroxide

An anti-corrosion coating for home appliances and a preparation method thereof, mainly composed of the following components: modified epoxy resin, TGIC curing agent, epichlorohydrin, organic soil, ammonium polyphosphate temperature-resistant additive, and phosphite antioxidant , sand texture agent, carbon black, precipitated barium sulfate, asbestos powder, nano silicon dioxide, chlorinated rubber, titanium dioxide, talcum powder, barium sulfate, anti-settling agent, defoaming agent, pigment, titanite white powder, bamboo fungus, water , ebony, white peony root, poria cocos, fritillaria, aurantium, ginger, PVA, starch, ammonia, AA, AAm mixture, ammonium persulfate, ammonium bisulfite, polyvinyl alcohol, cross-linking agent, liquid low molecular weight polyamide, Casein, sodium hydroxide, hydroquinone, urea, silane coupling agent. The paint prepared by this method has no peculiar smell, the formaldehyde content is far lower than the national standard, and releases a unique fragrance at the same time. It is suitable for use on household appliances and furniture, has high temperature resistance and cold resistance, and effectively solves the shortcomings of existing paints.

Owner:ANHUI HUAHUI SUYE TECH SHARE CO LTD

A method of desulfurization and denitration at the same time

ActiveCN103349900BCompliance with emission standardsLow costDispersed particle separationAmmonium nitrate fertilisersReducing agentNH3 compound

Owner:ASIA PACIFIC ENVIRONMENTAL CORP

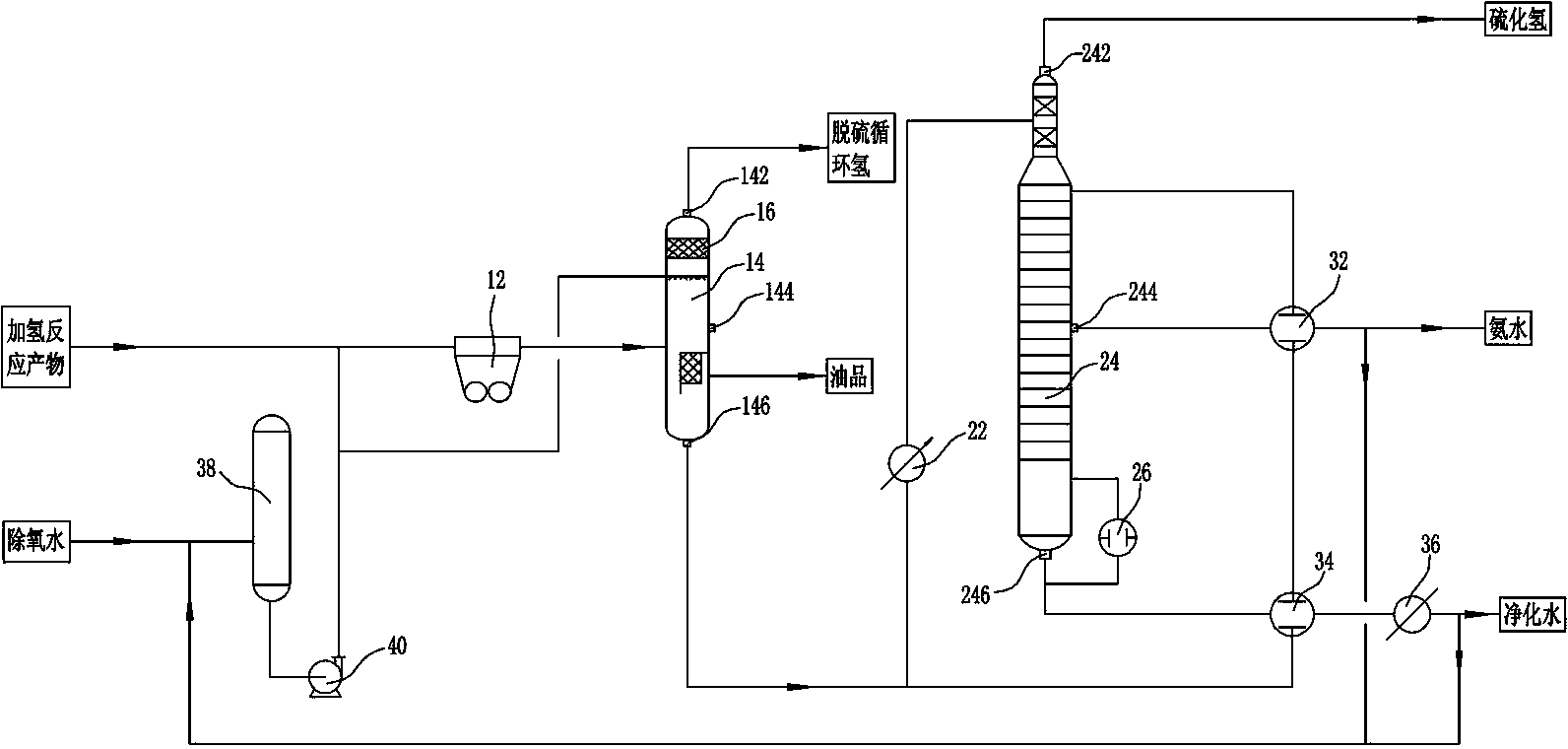

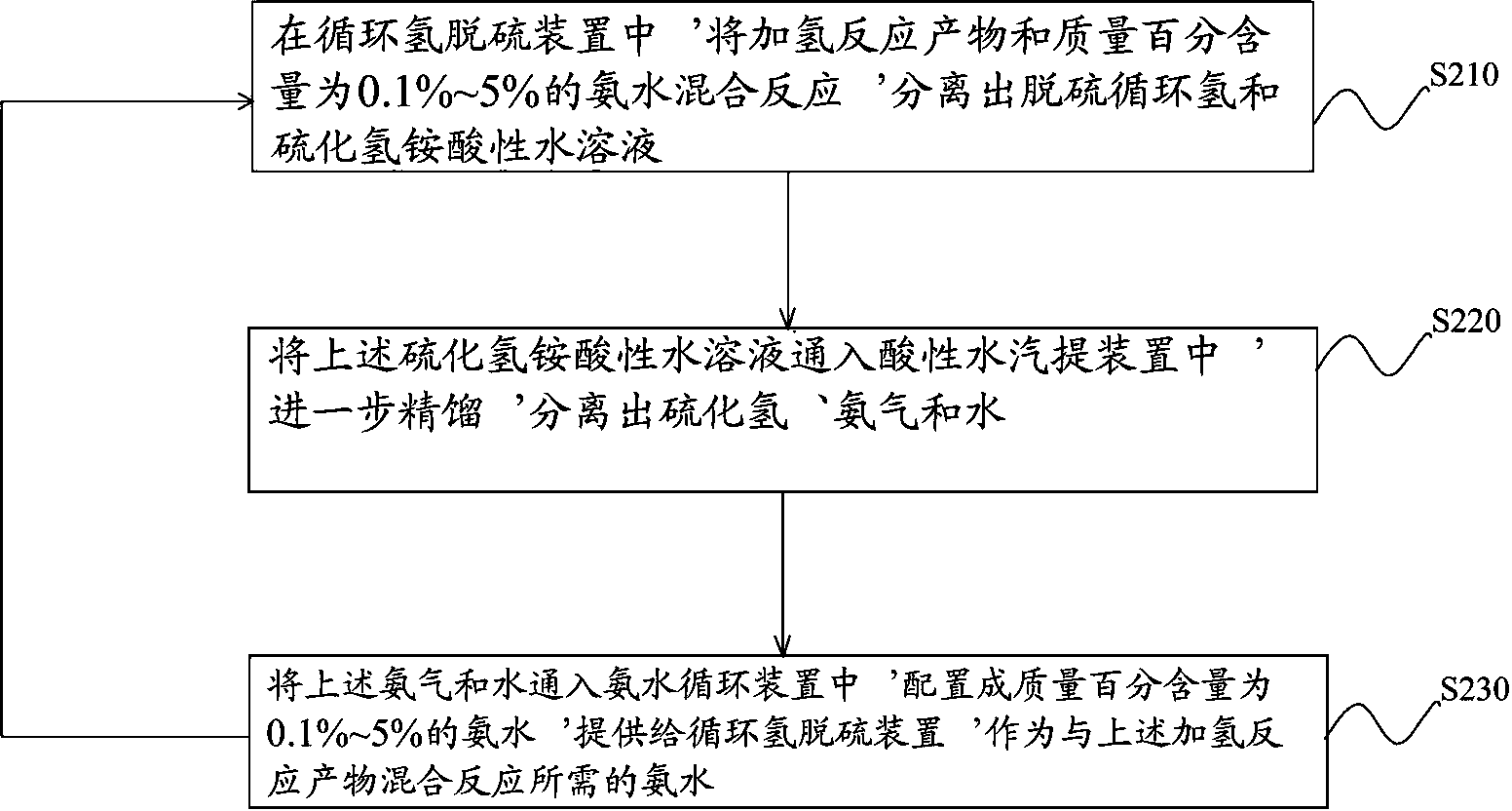

Recycle hydrogen desulfurization system and method

ActiveCN103865567AImprove responseSimple processRefining to eliminate hetero atomsHydrogenation reactionAmmonium hydrosulfide

The invention provides a recycle hydrogen desulfurization system. The system comprises a recycle hydrogen desulfurizing device, an acidic water steam stripping device and an ammonia water circulating device, wherein the recycle hydrogen desulfurizing device is used for mixing a hydrogenation reaction product with ammonia water of which the content in mass percentage is 0.1%-5% for reaction, and separating out desulfurized recycle hydrogen and ammonium hydrosulfide acidic water solution; the acidic water steam stripping device is connected with the recycle hydrogen desulfurizing device and used for further rectifying the ammonium hydrosulfide acidic water solution separated out by the recycle hydrogen desulfurizing device so as to separate out hydrogen sulfide, ammonia gas and water; the ammonia water circulating device is respectively connected with the acidic water steam stripping device and the recycle hydrogen desulfurizing device and used for mixing the ammonia gas and the water separated out by the acidic water steam stripping device and then preparing the ammonia water of which the content in mass percentage is 0.1%-5%, and the ammonia water is supplied to the recycle hydrogen desulfurizing device and used as the ammonia water for a mixing reaction with the hydrogenation reaction product. The invention also provides a recycle hydrogen desulfurization method. The recycle hydrogen desulfurization system and the recycle hydrogen desulfurization method are simple in process, low in power consumption and also low in equipment cost.

Owner:CHANGLING PETRO CHEM ENG DESIGN

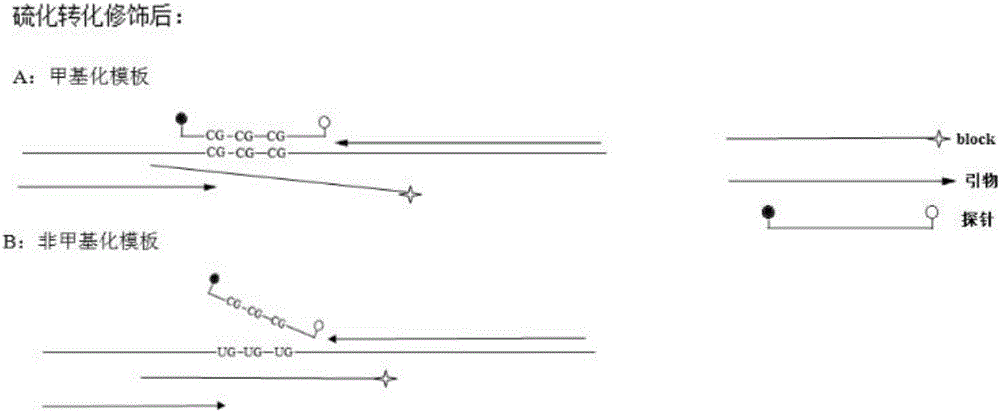

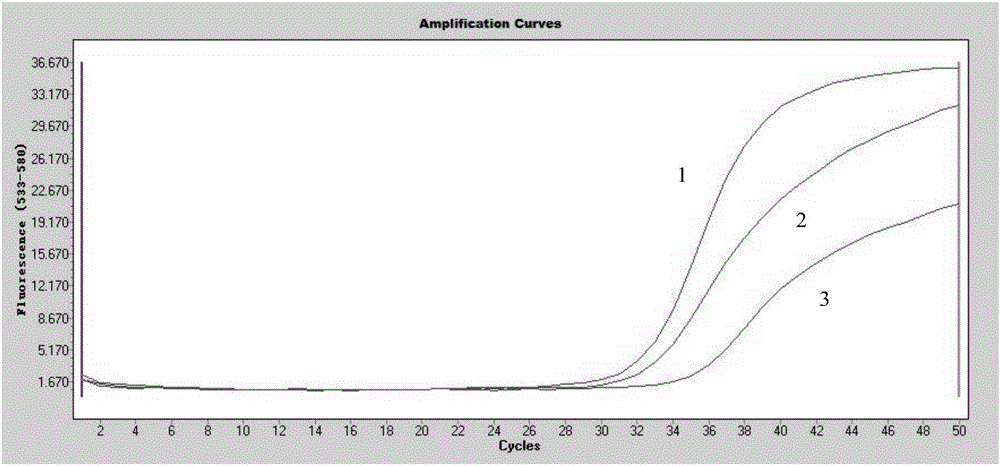

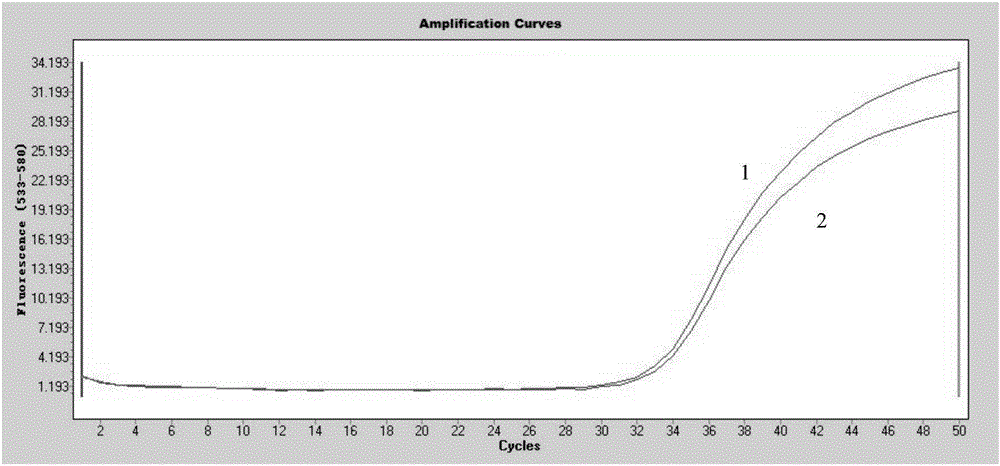

Vulcanizing agent in gene methylation detection and application thereof

InactiveCN106755391AImprove solubilitySimple and time-saving preparationMicrobiological testing/measurementDNA methylationVulcanization

The invention discloses a vulcanizing agent used in gene methylation detection, a matched kit and a detection method thereof. According to the vulcanizing agent, a mixed solution of ammonium hydrogen sulfite and anhydrous sodium sulfite is used as a DNA-methylation vulcanizing conversion reagent. Compared with the DNA-methylation vulcanizing conversion and modification method widely applied on the market, the method disclosed by the invention has the advantages that (1) anhydrous sodium sulfite is extremely easy to dissolve in ammonium hydrogen sulfite, the preparation of the vulcanizing reagent is simple and has a time-saving effect; (2) the whole process of the method only needs 1 hour, and high-temperature unwinding at 98 DEG C is not needed, so that the experimental operation is simple and fast; (3) the vulcanization is complete, and methylation of target genes can be still detected under the background of existence of (90%) non-methylated DNA; (4) the vulcanizing efficiency is high, and all 0.1ng positive DNA can be still detected by the vulcanizing conversion and modification method provided by the invention; and (5) the whole system does not contain toxic and harmful substances and has no hazard for testing personnel and environment, so that the whole system is safe.

Owner:JIANGSU MICRODIAG BIOMEDICINE TECH CO LTD

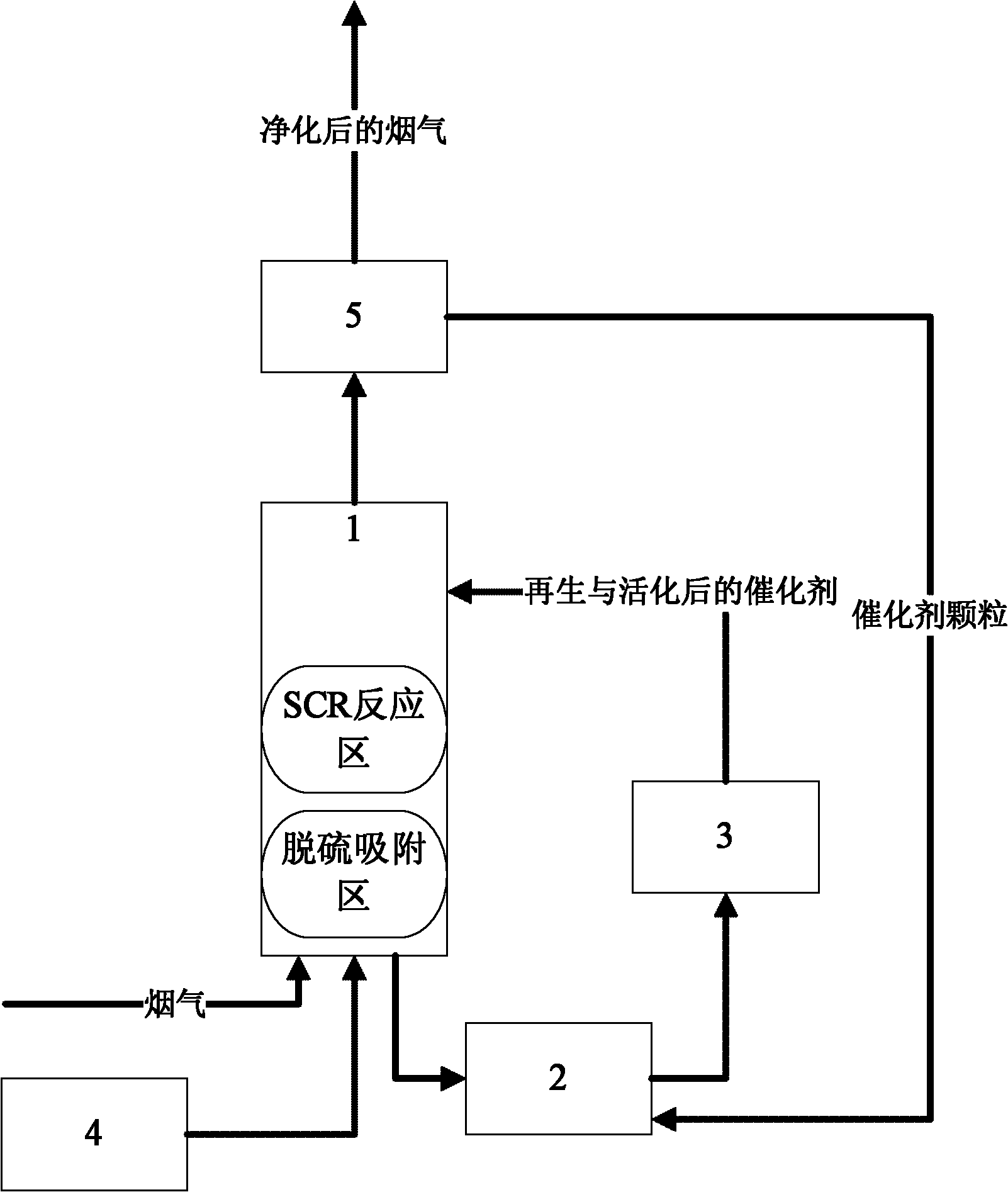

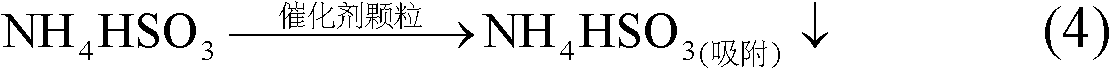

Fluidized bed-based flue gas combined desulfurization and denitration process

ActiveCN102512952BIncrease profitAchieve recyclabilityDispersed particle separationPtru catalystBoiler furnace

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Method for removing copper ions in zinc sulfate solution

InactiveCN105400955AEasy to recycleRaise the gradeProcess efficiency improvementSulfateReaction temperature

The invention provides a method for removing copper ions in a zinc sulfate solution. According to the method, ammonium hydrogen sulfite is used as a reducing agent for removing the copper ions in the zinc sulfate solution, the PH value of the zinc sulfate solution is 4.0-4.5, and the concentration of the copper ions in the zinc sulfate solution is 1-10 g / L. The method specifically comprises the following steps that the zinc sulfate solution is added into a reaction tank and is heated up to 45-55 DEG C; ammonium hydrogen sulfite is added for reaction, the reaction time is 25-30 min, and the reaction temperature is 45-55 DEG C; the copper ions in the zinc sulfate solution are changed to be in a cuprous oxide form from a bivalence form and are separated from the zinc sulfate solution; solid-liquid separation is conducted after reaction is completed, and the zinc sulfate solution without the copper ions and copper-bearing filter residues are obtained.

Owner:HUNAN LIHONG NEW MATERIAL TECH CO LTD

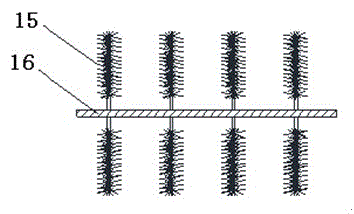

Crystallization tower for gas phase reaction

ActiveCN106345135AIncrease the attachment areaEasy to peel offSublimationAcid waterAmmonium hydrosulfide

The invention discloses a crystallization tower for gas phase reaction. The crystallization tower comprises an upper seal head, a tower body and a lower seal head, wherein a gas outlet is formed in the upper seal head; a gas inlet and a material outlet are formed in the lower seal head; the tower body comprises a cooling section and a crystallizing section from bottom up; a heat removing assembly is arranged in the cooling section; a tower tray is arranged in the crystallizing section; the tower tray comprises a tower tray plate and a crystallizing column fixed on the tower tray plate. The crystallization tower provided by the invention has a large surface area capable of being attached with crystal substances, has crystals easy to remove and stack on the tower tray, is suitable for the crystallization process of ammonium hydrosulfide during acid water treatment in a refinery plant, and is especially suitable for the separation process of hydrogen sulfide in an acid gas containing carbon dioxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

Bathroom cleaning and deodorizing agent

InactiveCN104083788AGood deodorizing effectImprove securityNon-ionic surface-active compoundsDetergent compounding agentsMonopotassium phosphatePotassium bisulfite

The invention discloses a bathroom cleaning and deodorizing agent. The agent is characterized by being prepared from the following raw materials in parts by weight: 2-5 parts of sodium hydrogen sulfite, 3-5 parts of potassium sulfite, 2-3 parts of ammonium hydrogen sulfite, 4-6 parts of monopotassium phosphate, 3-5 parts of potassium metabisulfite, 2-6 parts of 4-phenylsulfamic acid, 2-3 parts of sodium alkyl benzene sulfonate, 2-5 parts of methanoic acid, 2-6 parts of sodium hexametaphosphate, 5-6 parts of sodium pyrophosphate, 2-5 parts of sodium tripolyphosphate, 2-3 parts of fatty alcohol-polyoxyethylene ether and 20-30 parts of pure water. The bathroom cleaning and deodorizing agent is suitable for cleaning and disinfecting bathtubs, bath towels and other bathroom goods in families, hotels, hairdressing places and bath places, has cleaning and disinfecting double functions, and has the advantages of good deodorizing effect, no specific temperature requirement and good safety.

Owner:李兆源

Method for removing nano-metal powder surface anions

ActiveCN104985175APromote decompositionReduce the amount of adsorptionMaterial nanotechnologyUltrasound - actionFluid phase

The invention provides a method for removing nano-metal powder surface anions. The method comprises the steps that 1, nano-metal powder obtained through a liquid phase reduction method is washed with pure water and centrifugally separated 2-3 times; 2, ultrasonic waves with the certain power and frequency are used for processing the wet nano-metal powder for 15-30 min with stirring, and the processed wet nano-metal powder is added with ammonium bicarbonate or ammonium hydrogen sulfite, then sufficiently stirred, processed in an ultrasonic mode, added with pure water and centrifugally separated; 3, the wet nano-metal powder is washed with pure water and centrifugally separated, washing is stopped after the pH value of supernatant liquid is measured to be smaller than or equal to 9, and the supernatant liquid is poured out; 4, mercaptan is added under the effect of stirring and ultrasonic waves, and stirring and ultrasonic processing continue to be carried out for 15-60 min, then, pure water is added, and centrifugal separation is carried out after sufficient stirring and ultrasonic wave decentralized processing; and 5, the nano-metal powder is washed with organic solution, centrifugally separated 2-3 times, then placed into a high-temperature hydrogen reduction furnace, added with hydrogen and dried at 200-300 DEG C, thereby forming the needed product. According to the method, the design is reasonable, technological conditions are moderate and operation is easy. The anion adsorption amount of the nano-metal powder processed by the method is greatly reduced.

Owner:GUANGDONG GUANGHUA SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com