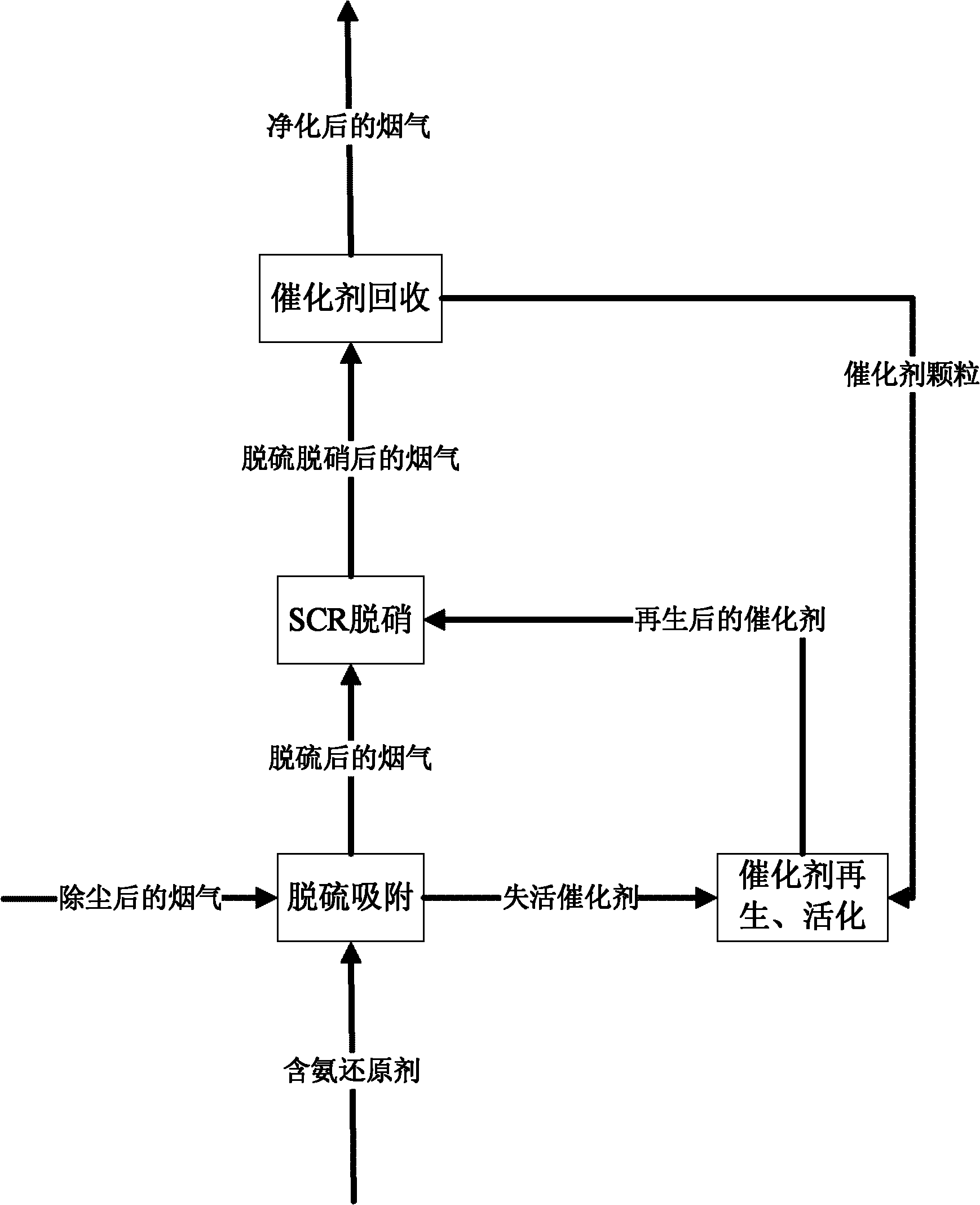

Fluidized bed-based flue gas combined desulfurization and denitration process

A desulfurization and denitrification, fluidized bed technology is applied in the field of low-temperature flue gas combined desulfurization and denitrification technology, which can solve problems such as affecting the removal efficiency of NOx, and achieve the effects of broad application prospects, small influence and high utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

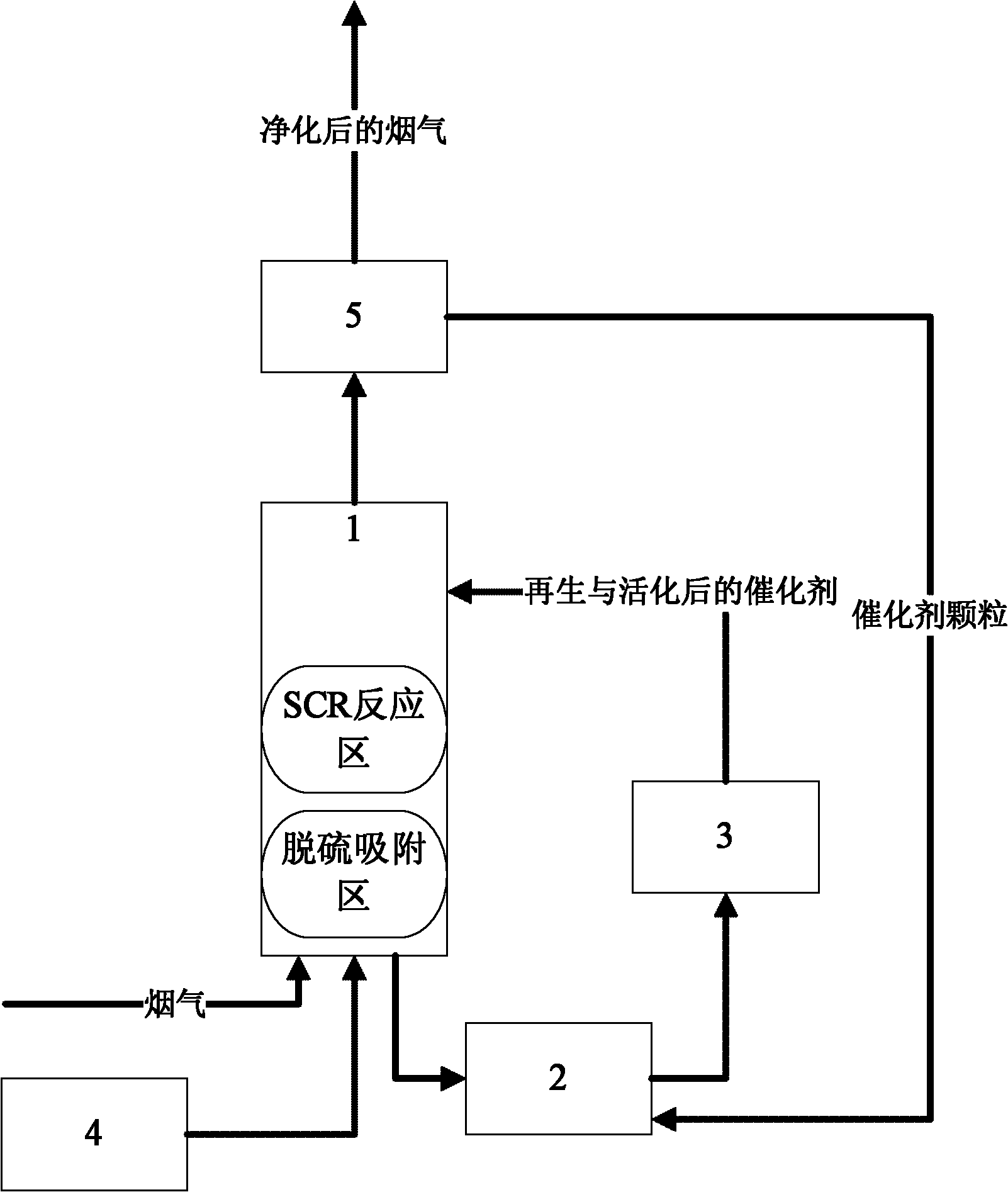

[0036] 1. Desulfurization and denitrification reaction

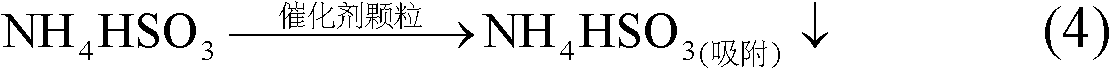

[0037] Dust-removed kiln flue gas (150°C, containing 800ppmSO 2 , 600ppmNO) into the desulfurization adsorption zone of the fluidized reaction tower with a total flow rate of 500L / s (flow velocity is 3m / s), and the substance used in the ammonia injection system is 16% ammoniacal liquor (mass fraction, density 0.94g / ml). NH 3 : SO 2 (Molar ratio) is 1.1:1, NH 3 : NO x (Molar ratio) was 1:1. The amount of ammonia injected is equal to the sum of the amount of ammonia consumed by the two types of acid gases. Ammonia and SO 2 The viscous substances generated by the reaction are adsorbed on the surface of the catalyst, and the mass of the particles increases and sinks into the desulfurization regeneration tank. The desulfurized "pure flue gas" undergoes a selective catalytic reduction reaction in the SCR reaction zone.

[0038] 2. Catalyst regeneration

[0039] Rinse the surface of the granular catalyst with deionized...

Embodiment 2

[0045] 1. Desulfurization and denitrification reaction

[0046] Dust-removed kiln flue gas (200°C, containing 500ppmSO 2 , 600ppmNO) into the desulfurization adsorption zone of the fluidized reaction tower with a total flow rate of 1000L / s (flow velocity is 6m / s), and the material used in the ammonia injection system is 20% ammonium carbonate solution. NH 3 : SO 2 (Molar ratio) is 1.5:1, NH 3 : NO x (Molar ratio) was 1.2:1. The amount of ammonia injected is equal to the sum of the amount of ammonia consumed by the two types of acid gases. Ammonia and SO 2 The viscous substances generated by the reaction are adsorbed on the surface of the catalyst, and the mass of the particles increases and sinks into the desulfurization regeneration tank. The desulfurized "pure flue gas" undergoes a selective catalytic reduction reaction in the SCR reaction zone.

[0047] 2. Catalyst regeneration

[0048] Rinse the surface of the granular catalyst with deionized water to remove solub...

Embodiment 3

[0054] 1. Desulfurization and denitrification reaction

[0055] Dust-removed kiln flue gas (180°C, containing 200ppmSO 2 , 500ppmNO) enter the desulfurization adsorption zone of the fluidized reaction tower with a total flow rate of 700L / s (flow velocity is 4.2m / s), and the substance used in the ammonia injection system is 4% ammoniacal liquor (mass fraction, density 0.98g / ml). NH 3 : SO 2 (Molar ratio) is 1.8:1, NH 3 : NO x (Molar ratio) was 1.1:1. The amount of ammonia injected is equal to the sum of the amount of ammonia consumed by the two types of acid gases. Ammonia and SO 2 The viscous substances generated by the reaction are adsorbed on the surface of the catalyst, and the mass of the particles increases and sinks into the desulfurization regeneration tank. The desulfurized "pure flue gas" undergoes a selective catalytic reduction reaction in the SCR reaction zone.

[0056] 2. Catalyst regeneration

[0057] Rinse the surface of the granular catalyst with deion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com