Super-high early-strength water reducing agent and processing method thereof

A super-early-strength, water-reducing agent technology, which is applied in the field of water-reducing agents for building materials, can solve the problems of high price and adverse effects on the strength of concrete in the later stage, and achieve a significant effect of improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

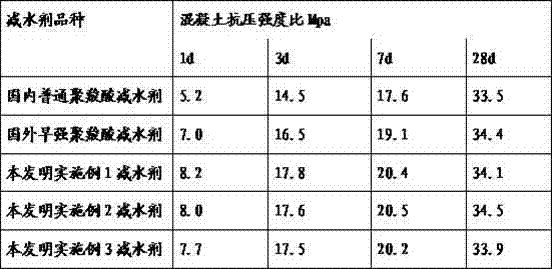

Examples

Embodiment 1

[0021] The raw material composition of an ultra-early strength superplasticizer:

[0022] a Allyl polyethylene glycol (molecular weight 2000-3000);

[0023] b Acrylic;

[0024] c acrylamide;

[0025] d amine persulfate;

[0027] f thioglycolic acid;

[0028] The molar ratio of the raw materials used is: a:b:c:d:e:f=1:3:0.5:0.06:0.03:0.03.

[0029] between the allyl polyethylene glycols.

[0030] The processing method of super early strength superplasticizer, its steps are as follows:

[0031] 1) Prepare mixed dripping solution: mix b, c and f with an appropriate amount of water to make 30% mixed dripping A;

[0032] 2) Synthesis reaction: first add an appropriate amount of water and a to the reaction kettle, stir to dissolve and heat up to 60 degrees, add d to the reaction kettle, continue stirring, and dropwise A uniformly dropwise into the reaction kettle within 1 hour, the dropwise addition ends After mixing e with an appropriate amoun...

Embodiment 2

[0034] The raw material composition of an ultra-early strength superplasticizer:

[0035] a Allyl polyethylene glycol;

[0036] b methacrylic acid;

[0037] c acrylamide;

[0038] d Potassium persulfate;

[0040] f mercaptoethanol;

[0041] The molar ratio of the raw materials used is: a:b:c:d:e:f=1:3:0.5:0.06:0.03:0.03.

[0042] between the allyl polyethylene glycols.

[0043] The processing method of super early strength superplasticizer, its steps are as follows:

[0044] 1) Prepare mixed dripping solution: mix b, c and f with an appropriate amount of water to make 50% mixed dripping A;

[0045] 2) Synthesis reaction: first add an appropriate amount of water and a to the reaction kettle, stir to dissolve and heat up to 60 degrees, add d to the reaction kettle, continue stirring, and dropwise A uniformly dropwise into the reaction kettle within 1 hour, the dropwise addition ends After mixing e with an appropriate amount of water, add it...

Embodiment 3

[0047] The raw material composition of an ultra-early strength superplasticizer:

[0048] a Allyl polyethylene glycol (molecular weight 2000-3000);

[0049] a Allyl polyethylene glycol;

[0050] b Acrylic and methacrylic acid;

[0051] c acrylamide;

[0052] d ammonium persulfate and potassium persulfate;

[0054] f mercaptoacetic acid and mercaptoethanol;

[0055] The molar ratio of the raw materials used is: a:b:c:d:e:f=1:3:0.5:0.06:0.03:0.03.

[0056] between the allyl polyethylene glycols.

[0057] The processing method of super early strength superplasticizer, its steps are as follows:

[0058] 1) Prepare mixed dripping solution: mix b, c and f with an appropriate amount of water to make 40% mixed dripping A;

[0059] 2) Synthesis reaction: first add an appropriate amount of water and a to the reaction kettle, stir to dissolve and heat up to 60 degrees, add d to the reaction kettle, continue stirring, and dropwise A evenly dropwise i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com