Treatment method and device of desulfurization tail gas

A treatment method, sulfuric acid tail gas technology, applied in the direction of fertilization equipment, separation methods, chemical instruments and methods, etc., can solve the problems of high power consumption, unstable compounds, etc., achieve energy saving, simple operation, and increase the utilization rate of sulfur Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

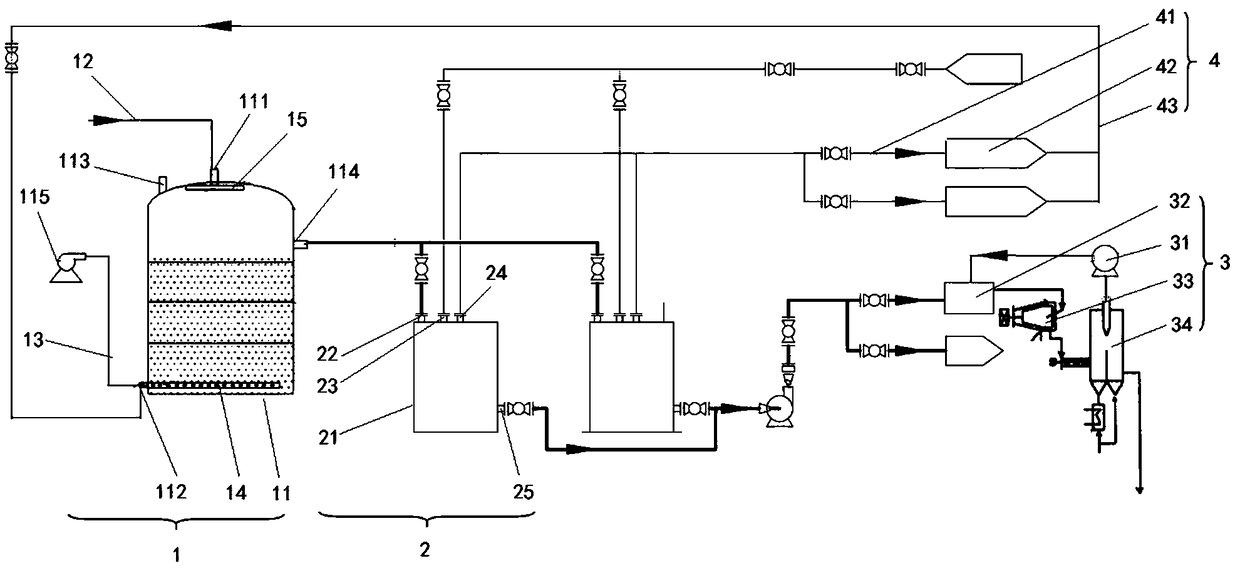

[0029] Such as figure 1 As shown, the embodiment of the present invention provides a treatment device for desulfurization tail gas, including a sulfuric acid tail gas absorption tower 1, a reaction kettle 2, an ammonium sulfate separation mechanism 3, and a sulfur dioxide separation mechanism 4;

[0030] Described sulfuric acid tail gas absorption tower 1 comprises sulfuric acid tail gas absorption tower main body 11, ammonia water feed pipeline 12, sulfurous flue gas feed pipeline 13 and the gas distribution pipe 14 that is positioned at the bottom of described sulfuric acid tail gas absorption tower main body, described sulfuric acid tail gas The main body 11 of the absorption tower is provided with an ammonia water feed port 111, a sulfur-containing flue gas feed port 112, a gas discharge port 113 and a discharge port 114, and the ammonia water feed port 111 is connected with the ammonia water feed pipe 12, The sulfur-containing flue gas feed port 112 is in communication wi...

Embodiment 2

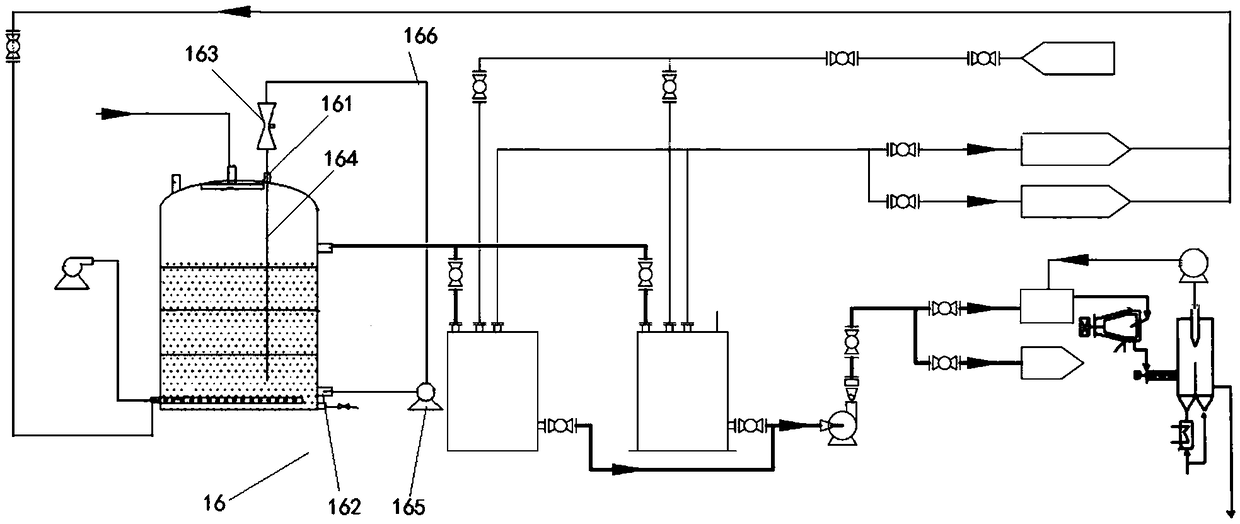

[0045] Such as figure 2 As shown, the embodiment of the present invention provides a treatment device for desulfurization tail gas, which also has the following features on the basis of Embodiment 1: the sulfuric acid tail gas absorption tower is also provided with a circulation pipeline 16, and the circulation pipeline 16 includes a jet device 163, lower liquid pipe 164, circulation pump 165, circulation pipe 166, and a circulation liquid inlet 161 and a circulation liquid outlet 162 positioned on the acid tail gas absorption tower, and the circulation liquid outlet 162 is connected with the circulation pipe 166 through the The ejector 163 is connected, and the ejector 163 is connected to the lower liquid pipe 164, and the lower liquid pipe 164 extends into the middle and lower part of the sulfuric acid tail gas absorption tower 1.

[0046] In order to increase the oxidation efficiency, it is necessary to carry out cyclic oxidation. The circulation pump 165 sends the liquid ...

Embodiment 3

[0048] The embodiment of the present invention provides a treatment method for desulfurization tail gas, using the above device, including the following steps:

[0049] Step 1. Using ammonia as a desulfurizer, the sulfuric acid tail gas absorption tower 1 fully contacts with the sulfur-containing flue gas gas-liquid, and the SO in the tail gas 2 NH 3 The reaction generates a mixed solution of ammonium sulfite, ammonium bisulfite, and ammonium sulfate, and the ammonia includes liquid ammonia, ammonia water or / and ammonium bicarbonate;

[0050] Step 2, the ammonium sulfite solution generated and the concentrated sulfuric acid are oxidized in the reactor 2 to obtain the ammonium sulfate solution, and sulfur dioxide gas is released simultaneously;

[0051] The ammonium sulfate solution that step 3, step 2 generate is sent to solid-liquid separator 33 through crystallizer, and the solid ammonium sulfate of separation is dried in ammonium sulfate drier 34, promptly obtains finished...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com