Novel environment-friendly formaldehyde-free dye-fixing agent and preparation method thereof

A color-fixing agent and environmentally friendly technology, applied in the field of printing and dyeing auxiliaries, can solve the problems of unfixed dyes, unqualified dyeing fastness, washing fading and staining, etc., to achieve environmental protection, good color fixing effect, and environmental protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

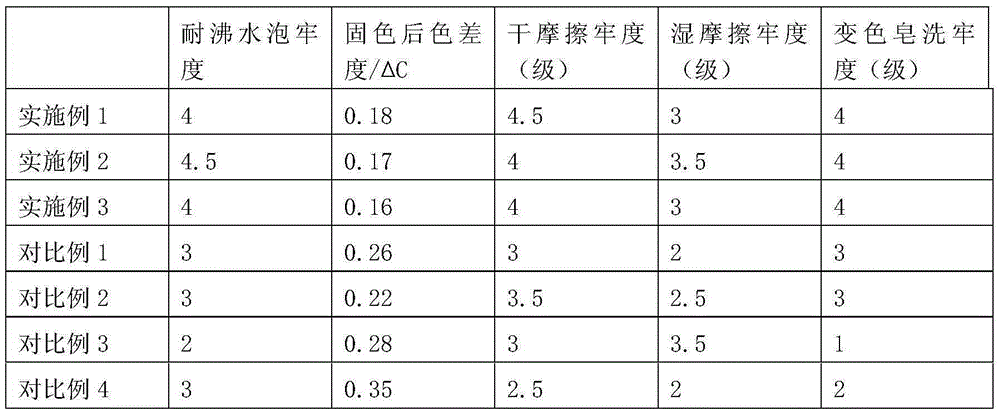

Examples

Embodiment 1

[0023] Environmentally friendly formaldehyde-free color fixing agent, including the following components by weight: 15 parts of acrylic acid; 2 parts of ammonium bisulfite; 1 part of epichlorohydrin; 2 parts of benzyltriethylammonium chloride; 8 parts of ammonium chloride chitosan; 4 parts of polyethylene polyamine resin polycondensate (polycondensation rate 40%); 0.3 part of persulfate; 1 part of fatty acid polyethylene glycol ester; 0.5 part of triethylenetriamine; methacrylic acid 2 parts of β-hydroxybutyl ester; 20 parts of deionized water.

Embodiment 2

[0025] Environmentally friendly formaldehyde-free color fixing agent, including the following components by weight: 18 parts of acrylic acid; 6 parts of ammonium bisulfite; 4 parts of epichlorohydrin; 3 parts of benzyltriethylammonium chloride; 10 parts of ammonium chloride chitosan; 5 parts of polyethylene polyamine resin polycondensate (polycondensation rate 40%); 3 parts of persulfate; 2 parts of fatty acid polyethylene glycol ester; 4 parts of triethylenetriamine; methacrylic acid 5 parts of β-hydroxybutyl ester; 40 parts of deionized water.

Embodiment 3

[0027] Environmentally friendly formaldehyde-free color fixing agent, including the following components by weight: 20 parts of acrylic acid; 8 parts of ammonium bisulfite; 5 parts of epichlorohydrin; 5 parts of benzyltriethylammonium chloride; 20 parts of ammonium chloride chitosan; 8 parts of polyethylene polyamine resin polycondensate (polycondensation rate 40%); 4 parts of persulfate; 3 parts of fatty acid polyethylene glycol ester; 5 parts of triethylenetriamine; methacrylic acid 8 parts of β-hydroxybutyl ester; 60 parts of deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com