Crystallization tower for gas phase reaction

A technology of gas phase reaction and crystallization tower, which is applied in crystallization equipment and the field of crystallization towers that process two kinds of gases reacting to form a solid phase. It can solve the problems of expensive desulfurization catalysts, low purity of sulfur products, and solid waste generation, and increase crystallization adhesion. Large area, large surface area, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

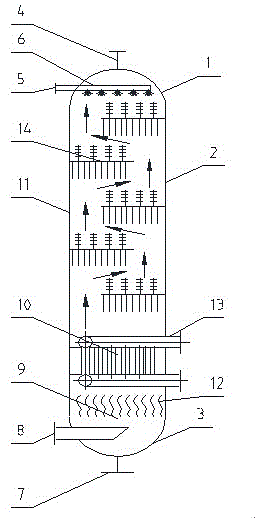

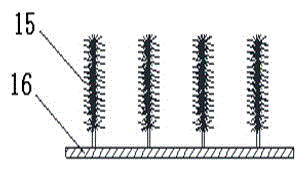

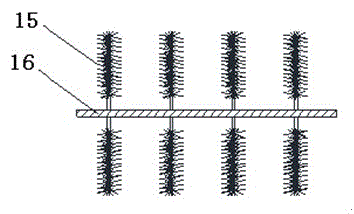

[0032] combine figure 1 The crystallization tower of the present invention is further described, the crystallization tower used for gas phase reaction of the present invention comprises an upper head 1, a tower body 2 and a lower head 3, and the upper head 1 is provided with a gas outlet 4 and a water inlet 5. , the water inlet 5 is connected with a water inlet distribution pipe 6, the water inlet distribution pipe 6 is provided with a number of nozzles, the lower head 3 is provided with a gas inlet 8 and a material outlet 7, and the tower body 4 consists of Bottom to top includes a feed mixing section 9, a cooling section 10 and a crystallization section 11, the feed mixing section 9 is provided with a gas phase distributor 12, the cooling section 10 is provided with a heat extraction component 13, and the crystallization section 11 is provided with There is a tray 14 including a tray plate 16 and a crystallization column 15 fixed on the upper surface of the tray plate 16 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com