Automatic intelligent production line for ribbon production

A production line and intelligent technology, applied in screen printing, printing, printing machines, etc., can solve problems such as poor printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

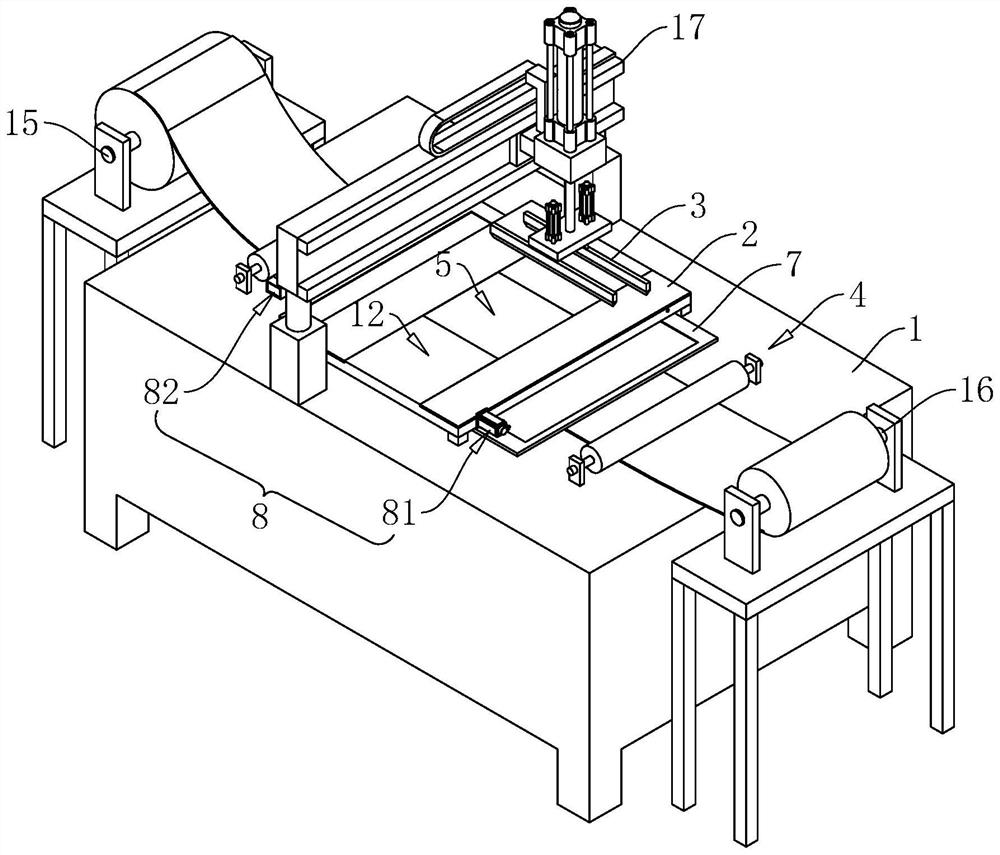

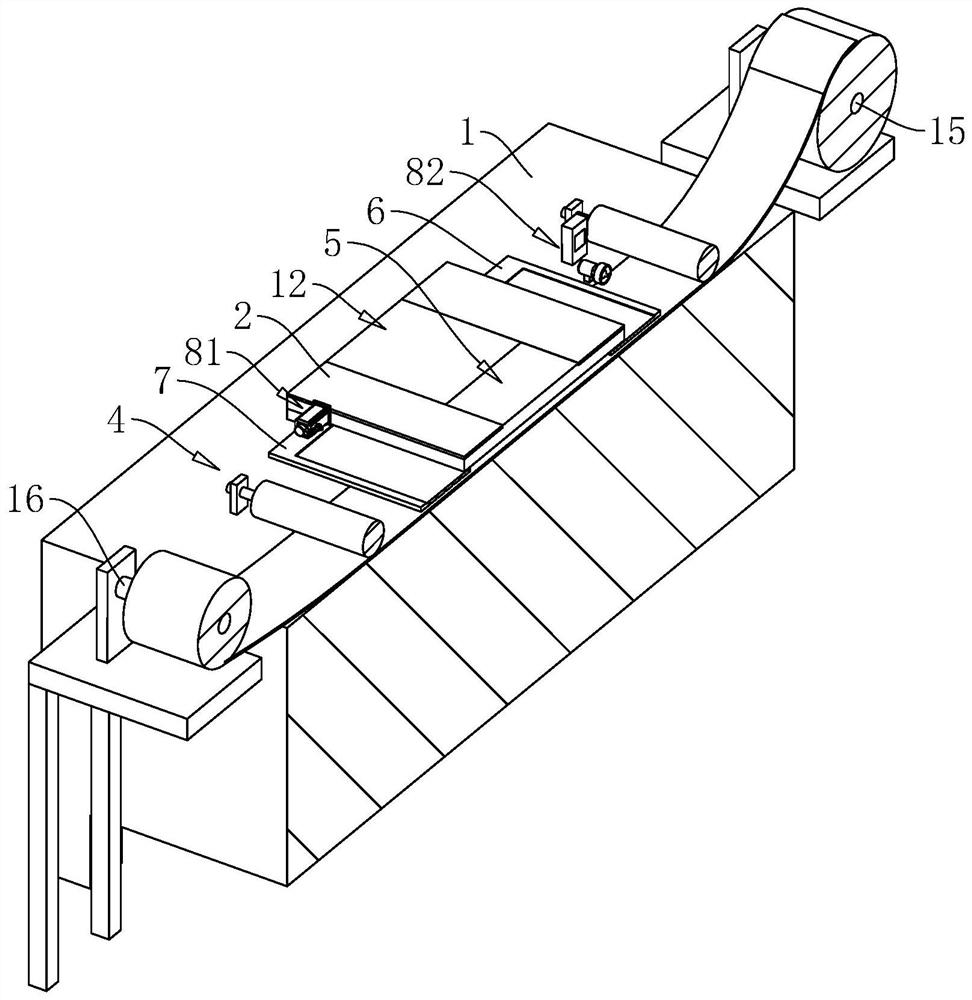

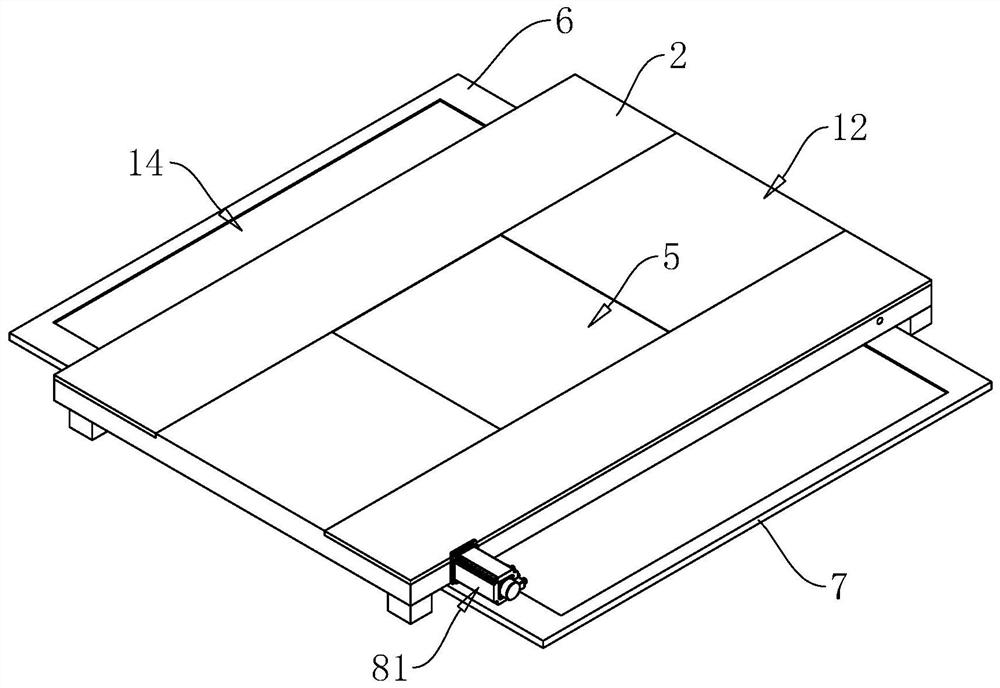

[0035] Attached to the following Figure 1-5 This application will be described in further detail.

[0036] The embodiment of the present application discloses an automated intelligent production line for ribbon production. refer to figure 1 and figure 2 , an automatic intelligent production line for ribbon production includes a printing platform 1 and a printing plate 2 and a scraper 3 arranged on the printing platform 1. One end of the printing platform 1 is rotated and provided with an unwinding roller 15, and the other end is rotated and provided with a take-up roller 15. Roller 16 , the substrate roll to be printed is rotated and erected on one end of the printing platform 1 through the unwinding roller 15 , and the free end of the substrate is wound on the other end of the printing platform 1 by the take-up roller 16 .

[0037] refer to figure 1 and figure 2 , the printing platform 1 is also provided with a transfer mechanism 4 for transferring the substrate. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com