A screen screen, double printing device, double printing machine and double printing process

A screen and screen technology, which is applied in the field of screen printing devices and processes, can solve the problems of difficulty in improving printing efficiency, affecting printing efficiency and quality, and insufficient rationality of double printing devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

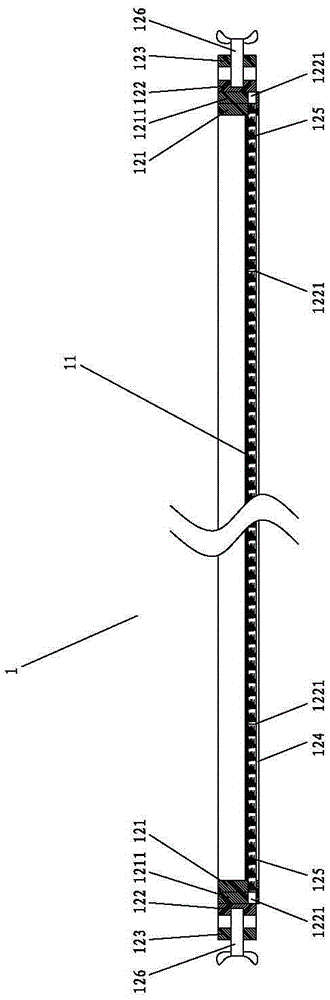

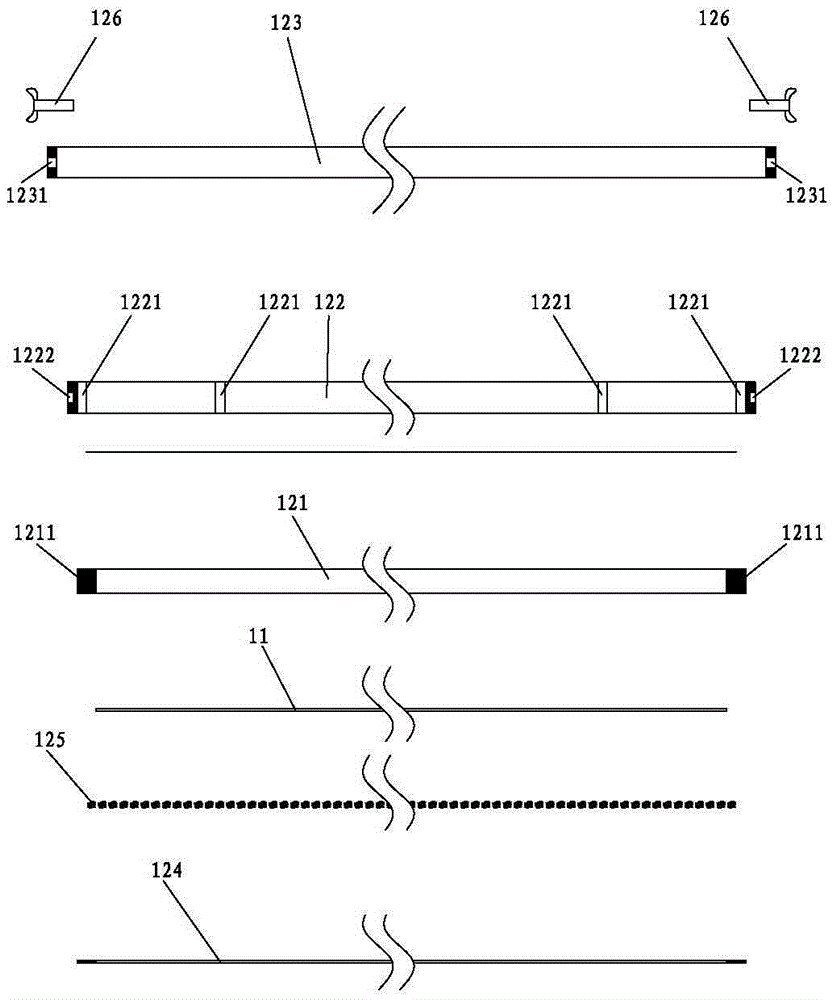

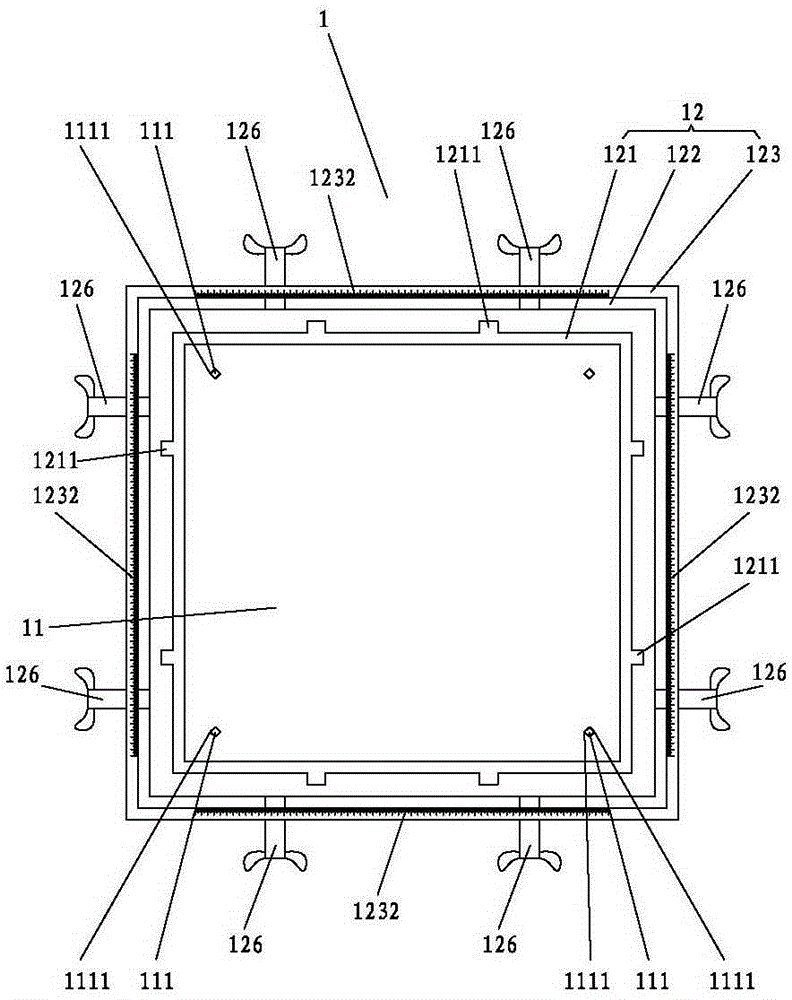

[0059] A kind of screen screen version 1 of the present invention, as Figure 1-3 As shown, it includes a screen 11 and a screen frame 12 carrying the screen 11 .

[0060] The screen frame 12 includes the inner screen frame 121, the middle screen frame 122 and the outer screen frame 123 which are set sequentially from the inside to the outside; the wire mesh 11 is connected with the inner screen frame 121; the middle screen frame 122 is matched with the inner screen frame 121 Outside, the inner surface of at least one pair of opposite frames of the middle screen frame 122 is formed with a chute 1221 extending along the thickness direction of the screen 11, and the outer surface of the inner screen frame 121 is formed with a matching slide rail 1211 corresponding to the chute 1221; The lower edge of the middle screen frame 122 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com