Special printer

A printing equipment and special technology, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of inability to meet supply demand, unsuitable for popularization and promotion, and high purchase cost, and achieve the goal of being conducive to popularization and popularization, simple in structure, and high in production. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

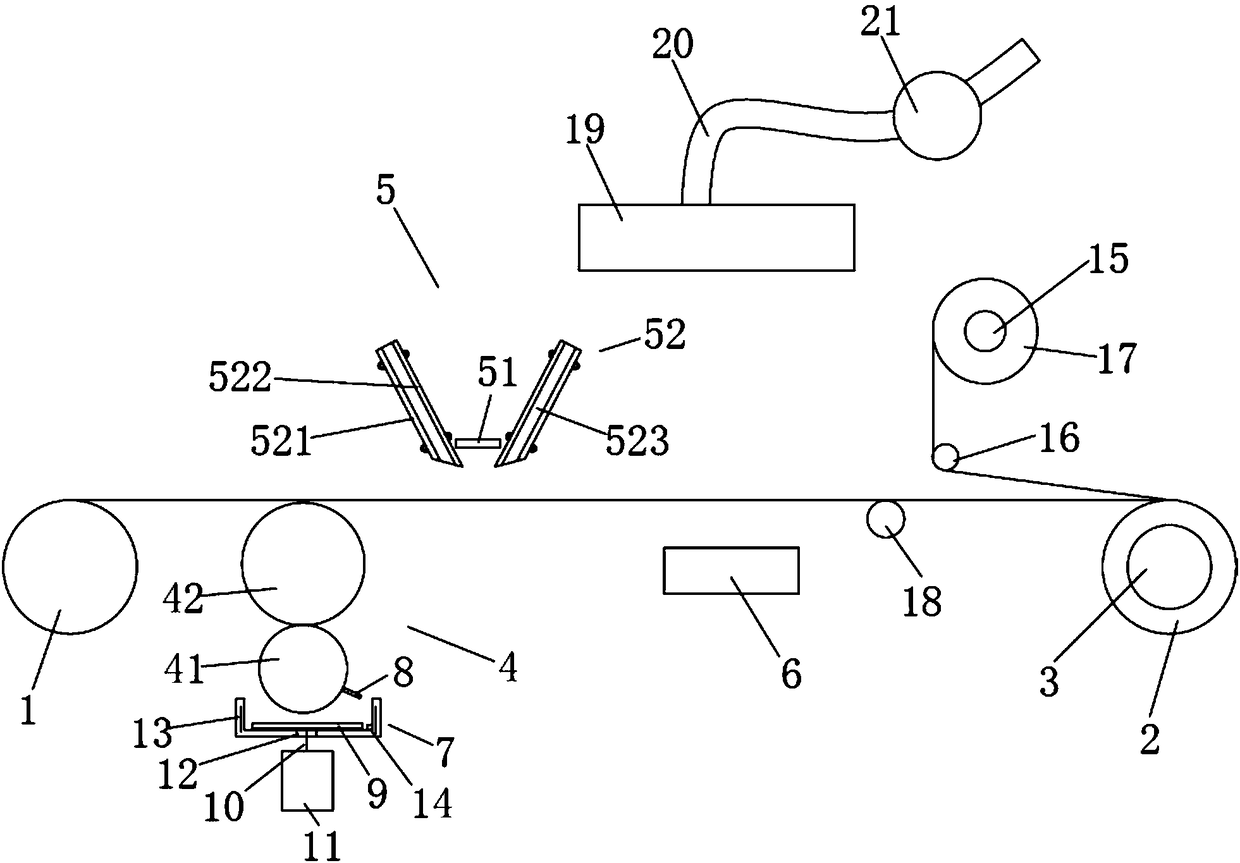

[0020] A special type of printing equipment, comprising a feed roller 1 and a take-up roller 2, the take-up roller 2 is connected to a first motor 3, the first motor 3 drives the take-up roller 2 to rotate, and the printing medium is rewound, and the take-up roller 1 and the receiving roller 2 are also provided with a printing device 4, a magnetic orientation device 5, and a curing device 6. The magnetic orientation device 5 is used to orient the magnetic pigment flakes in the magnetic ink to keep a good shape. The printing device 4 Comprising an inking roller 41, a printing roller 42 is arranged above the inking roller 41, an ink tray 7 is arranged at the lower end of the inking roller 41, the ink tray 7 is equippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com