Transmission shaft

A technology of transmission shaft and No. 1, applied in the field of transmission shaft, can solve the problems affecting the printing of printed products, surface roughness, technical scheme limitation, etc., and achieve the effect of improving the effect and improving the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

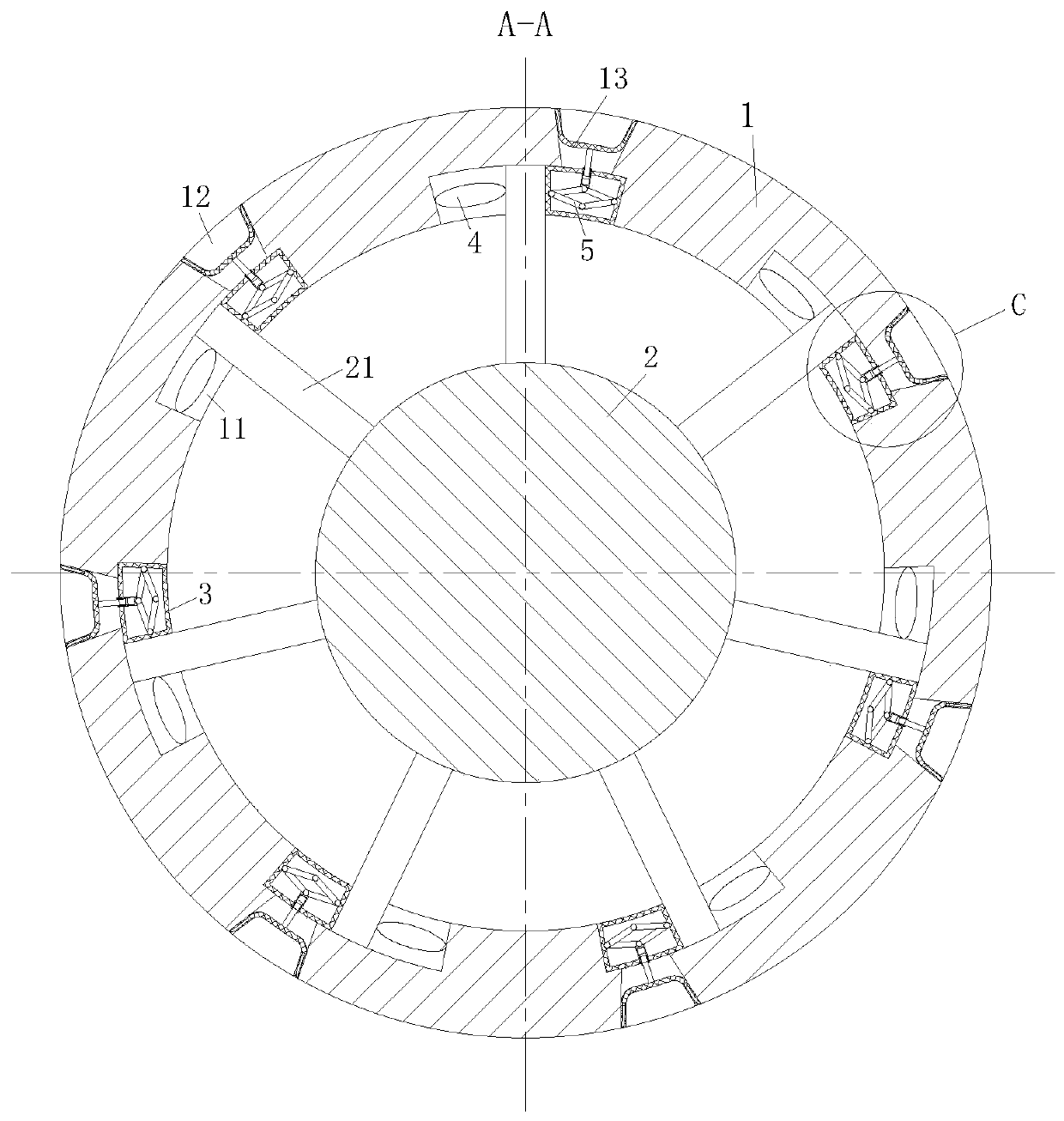

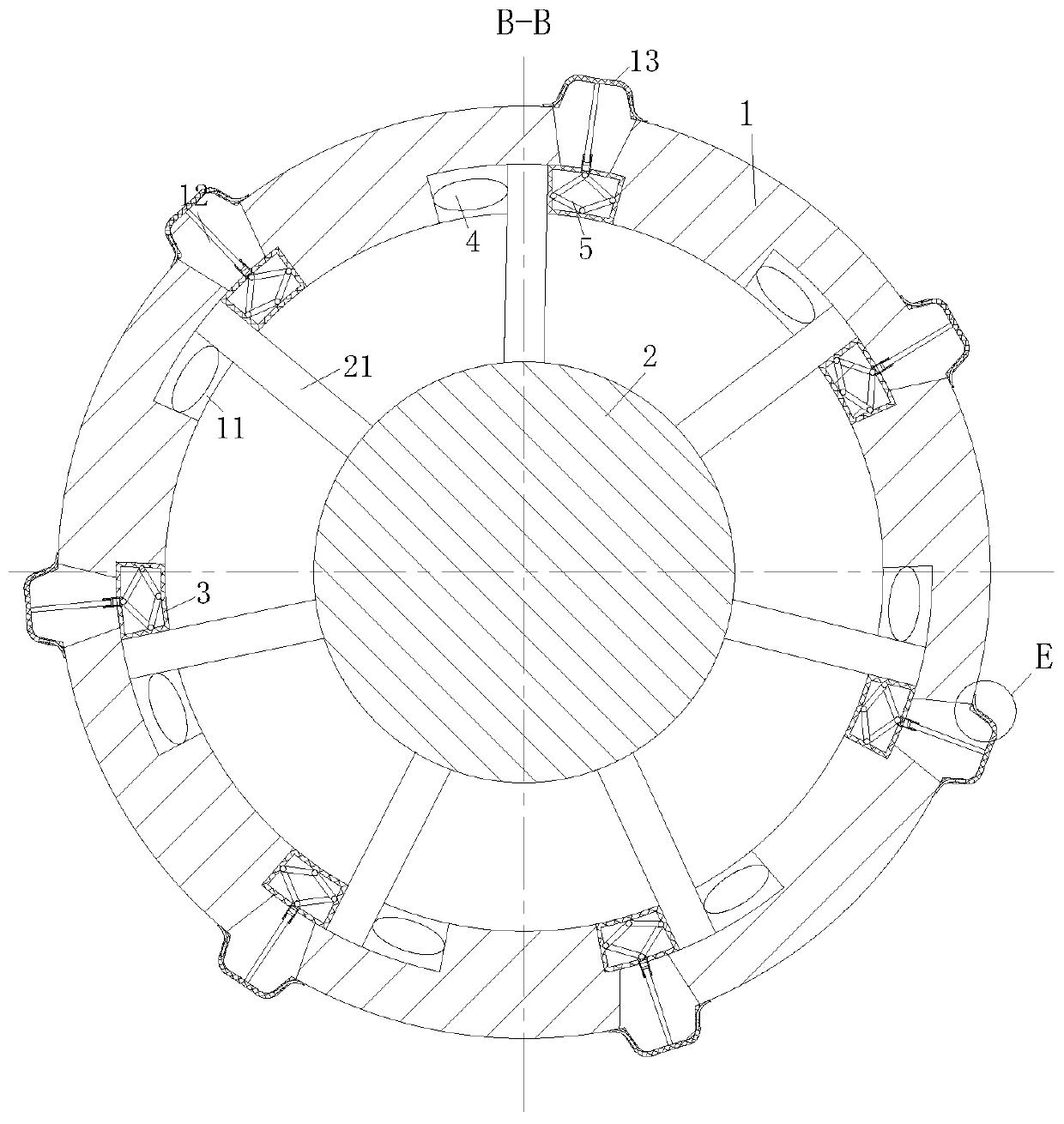

[0027] As a specific embodiment of the present invention, the No. 1 hole 131 is an oblique hole; through the oblique No. 1 hole 131, it is convenient for the gas to clean the impurities on the outer ring of the outer shaft 1; through this design, the present invention, The gas is precisely blown to the outer ring of the outer shaft 1, and the residual substances on the outer ring of the outer shaft 1 are cleaned, thereby improving the cleaning effect on the transmission shaft.

Embodiment approach

[0028] As a specific embodiment of the present invention, the shrapnel 13 is provided with a No. 1 slot 132, and the No. 1 slot 132 is provided with a cleaning block 133, and the No. 1 slot 132 communicates with the No. 1 hole 131; the cleaning block 133 It is fixed on the side wall of the No. 1 groove 132 by a spring. In the initial state, the cleaning block 133 is located in the No. 1 groove 132; through the cleaning block 133, the cleaning of impurities on the outer ring of the outer shaft 1 is increased; when the shrapnel 13 is deformed and turned over , due to gravity, the cleaning block 133 will slide out of the No. 1 groove 132, and when the cleaning block 133 slides out of the No. 1 groove 132, the remaining substances on the outer ring of the outer shaft 1 will be cleaned, thereby improving the cleaning effect of the transmission shaft; When the shrapnel 13 loses the function of gas, the shrapnel 13 returns to its original shape, and the cleaning block 133 returns to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com