3D printing head with air inlet device and cooling method of printing head

A technology of air inlet device and print head, which is applied in the direction of coating device, 3D object support structure, manufacturing tools, etc. It can solve the problems of easy breakage, incomplete curing, and insufficient structural strength of the product, and achieve the effect of ensuring printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

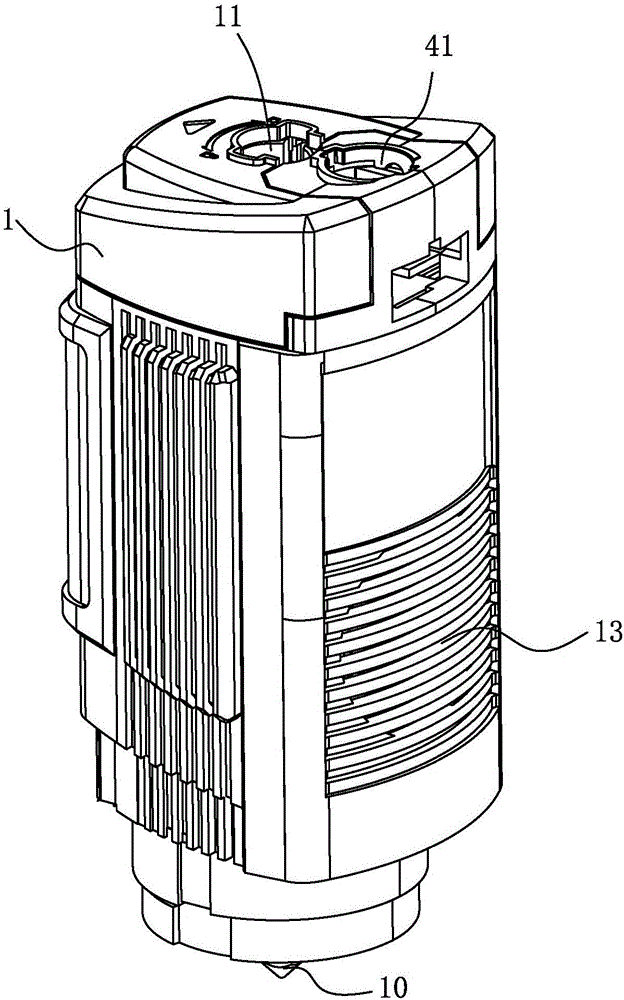

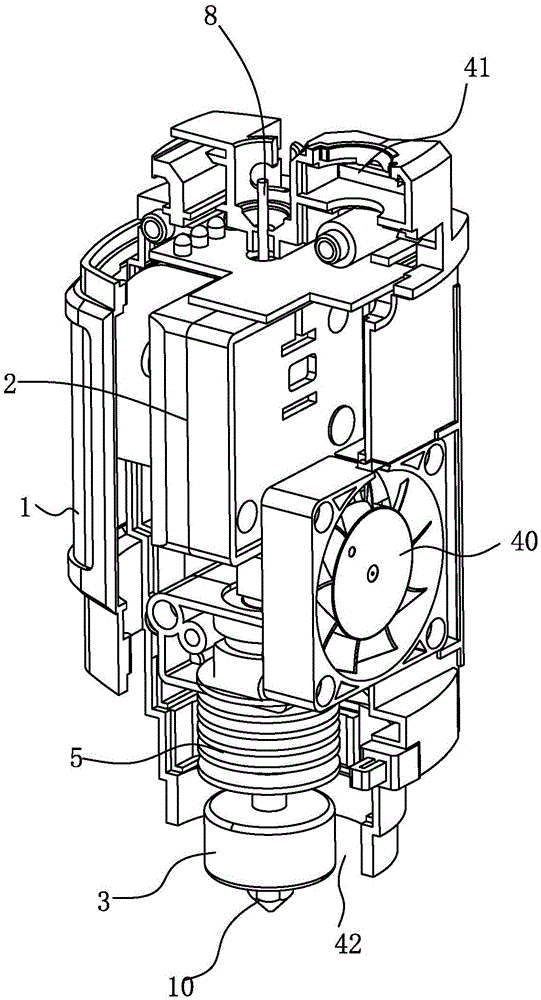

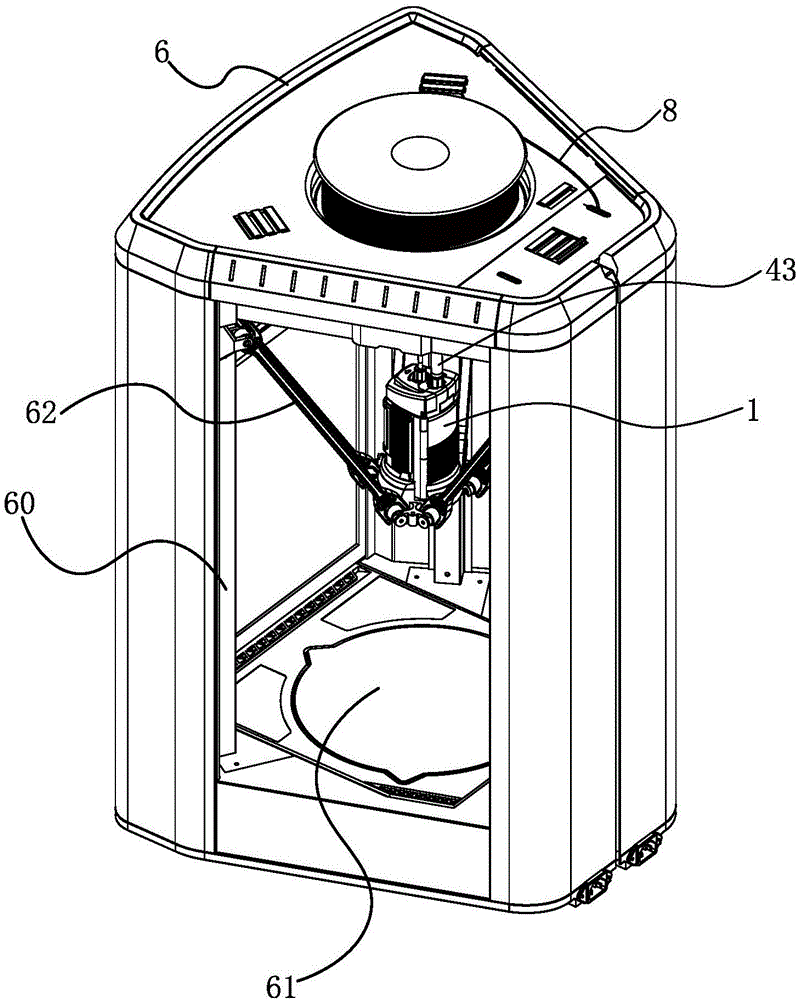

[0039]See figure 1 , 2 , 3, and 4, this is the first embodiment of the present invention, which is a 3D printing head with an air inlet device, the printing head is installed in the printer body 6, a cavity 60 is formed in the printer body 6, and the printing The head works in the cavity 60 . The print head is driven by the mechanical arm 62, which can realize the operation in the X / Y / Z direction. The mechanical arm 62 has been recorded in many patent documents as a mature technology. , US20120171383 A1, and US patent documents of 20130049261A1, all of which propose related technical solutions based on this mechanical arm. This kind of mechanical arm has the advantages of high speed and high precision compared with the general horizontal three-dimensional mechanical arm.

[0040] A printing platform 61 is installed below the cavity 60, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com