Three-dimensional printer and printing method thereof

A three-dimensional printer and three-dimensional printing technology, applied in the direction of additive processing, etc., can solve the problems of inconvenient splicing, layering, and no heat preservation effect, and achieve the effect of overcoming poor adaptability, overcoming high cost, and ensuring printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

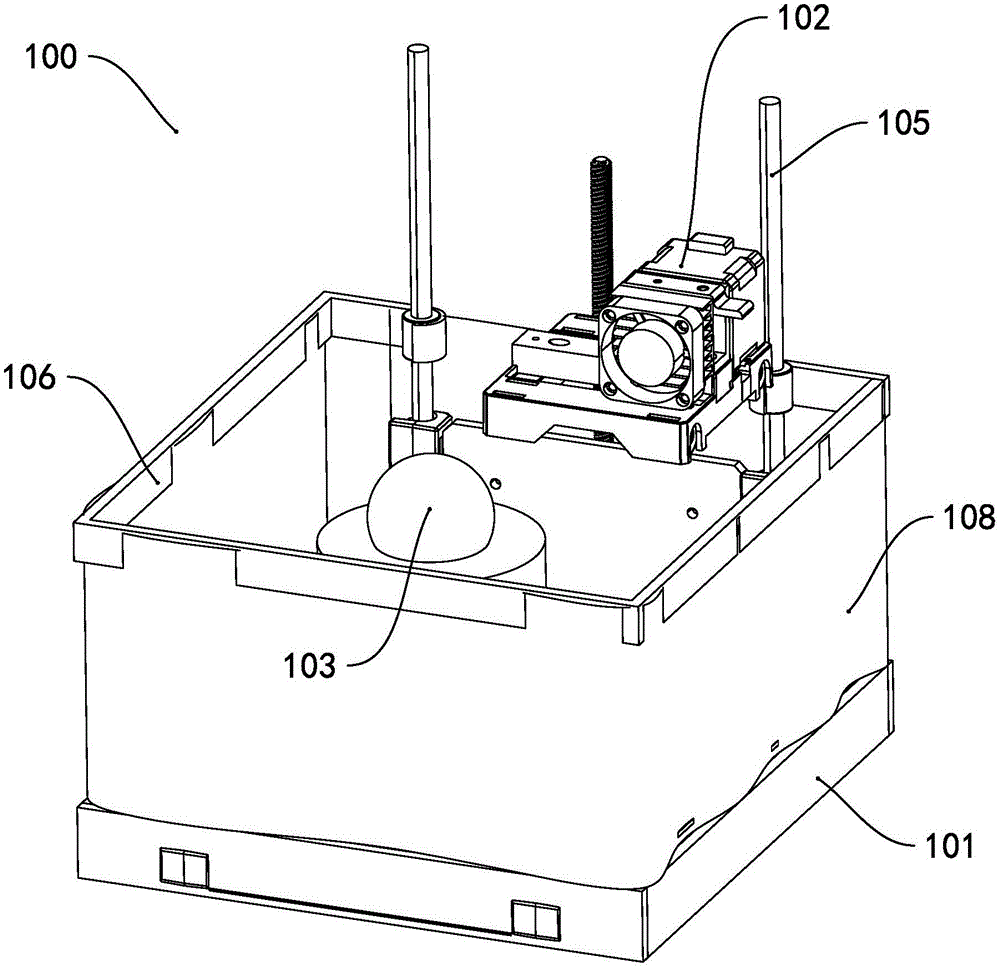

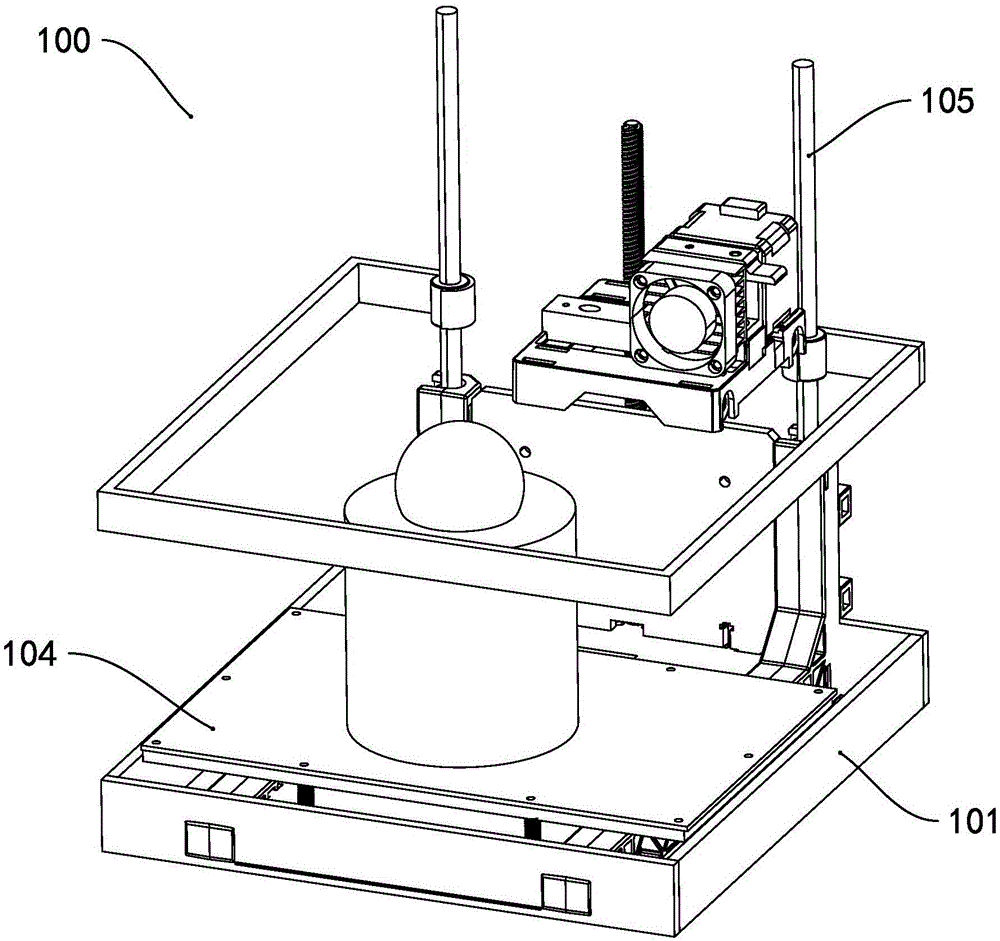

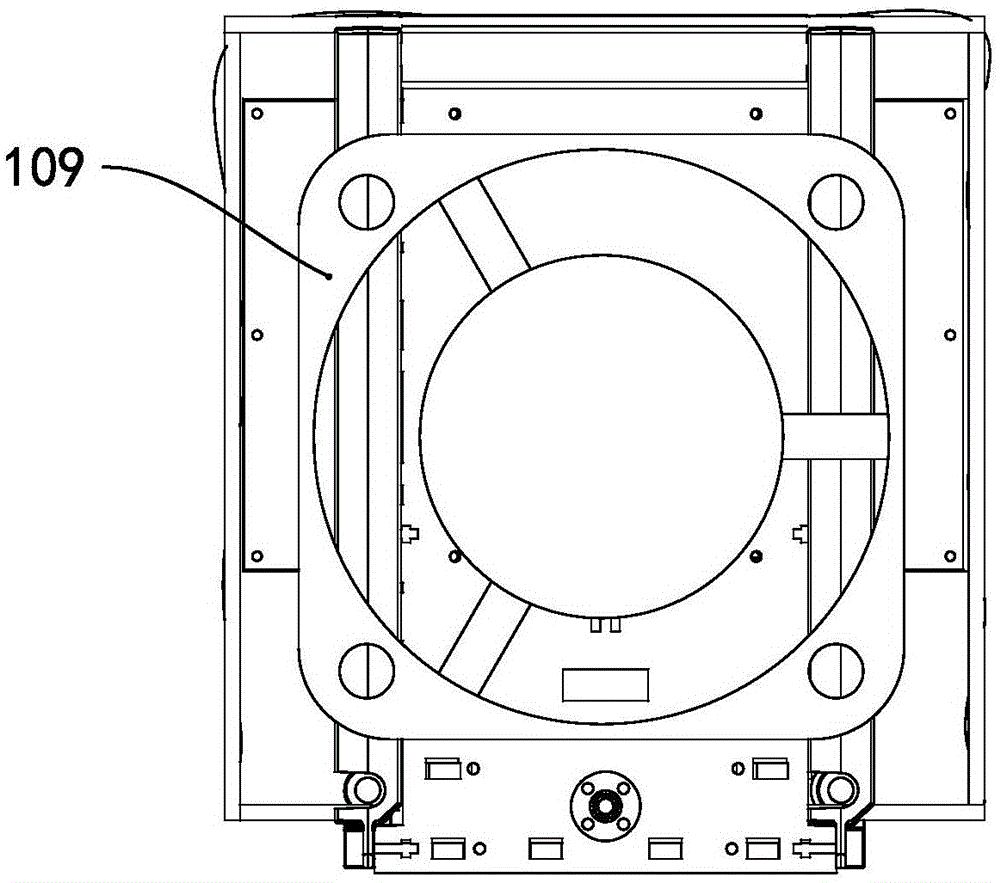

Embodiment 1

[0029] Such as figure 1 , figure 2 , image 3 As shown, the three-dimensional printer 100 provided by the present invention includes a printing platform 101, a printing head 102 arranged above the printing platform 101, a forming base 104 fixed on the printing platform 101 and carrying a three-dimensional printing entity 103, and an edge perpendicular to the printing platform 101 A guide rail 105 is arranged in a direction, a heat preservation component 108 is arranged around the printing platform 101, and a heating device 109 is arranged under the printing platform 101. The heat preservation component 108 is made of stretchable elastic material, such as high temperature resistant polyester film (PET film), high temperature resistant polypropylene film (PP film), etc. The upper end is connected with the fixed frame 106 of the printing platform 101, The lower end is sleeved on the forming seat 104. The heat preservation component 108 is connected to the guide rail 105 so that t...

Embodiment 2

[0032] Such as Figure 4 , Figure 5 As shown, preferably, the thermal insulation component 208 of the three-dimensional printer 200 may be a double-layer inflatable device, and a side facing the three-dimensional printing entity 203 is provided with a plurality of small holes (not shown). During printing, hot air is charged between the two layers of the thermal insulation component 208, so that the inflated thermal insulation component 208 slowly expands and rises in a direction substantially perpendicular to the molding seat, and always maintains a certain distance from the three-dimensional printing entity 203. Under the continuous action of the fan 207, the hot air generated by the heating device under the printing platform 201 is transferred to the space enclosed by the printing platform 201 and the heat preservation component 208, and forms a circulation in the space.

[0033] The present invention provides a printing method for a three-dimensional printer, which uses the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com