Two-dimension code printing quality online assessment method

A printing quality, two-dimensional code technology, applied in the direction of instruments, character and pattern recognition, computer components, etc., can solve the problems of two-dimensional barcode wear, pattern fading, and affecting scanning efficiency, so as to reduce equipment errors and failure rates, Avoid wasting time and financial resources and ensure the effect of printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

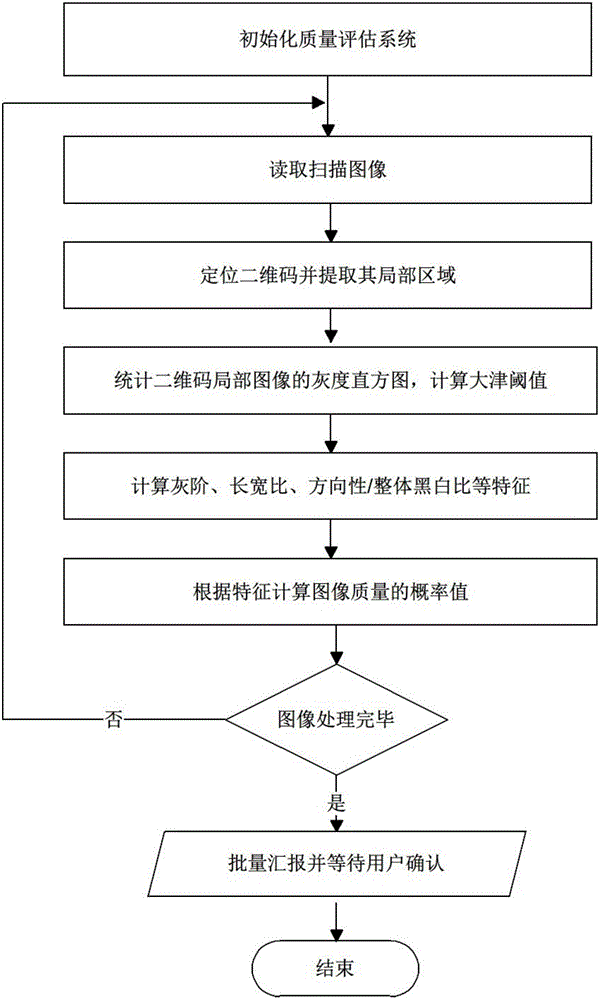

[0036] The present invention will be further described below in conjunction with specific embodiments. The online evaluation method of two-dimensional code printing quality provided by the present invention is based on digital image processing technology, and is used to detect the output quality of two-dimensional code printers and the preservation quality of two-dimensional codes. The hardware devices used include digital scanners, two-dimensional code printers, business point terminal computers and cloud network servers. The two-dimensional code printers and digital scanners are connected to the business point terminal computers to realize printing at each node according to actual needs. Two-dimensional code and scan the formatted form containing the two-dimensional code; and the terminal computer of the business point is connected to the Internet to communicate with the network server in the cloud, and the terminal computer of the business point transmits the digital scanned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com