FPC (flexible printed circuit board) substrate continuous and uninterrupted screen printing ink operation line

A technology of screen printing and screen printing machine, which is applied in the direction of screen printing machine, printing machine, printing machine, etc. It can solve the problems of uninterrupted printing and non-stop printing, etc., and achieves fast printing speed, low cost and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In the following, specific implementations of the high-efficiency placement machine of the present invention will be introduced in conjunction with the accompanying drawings.

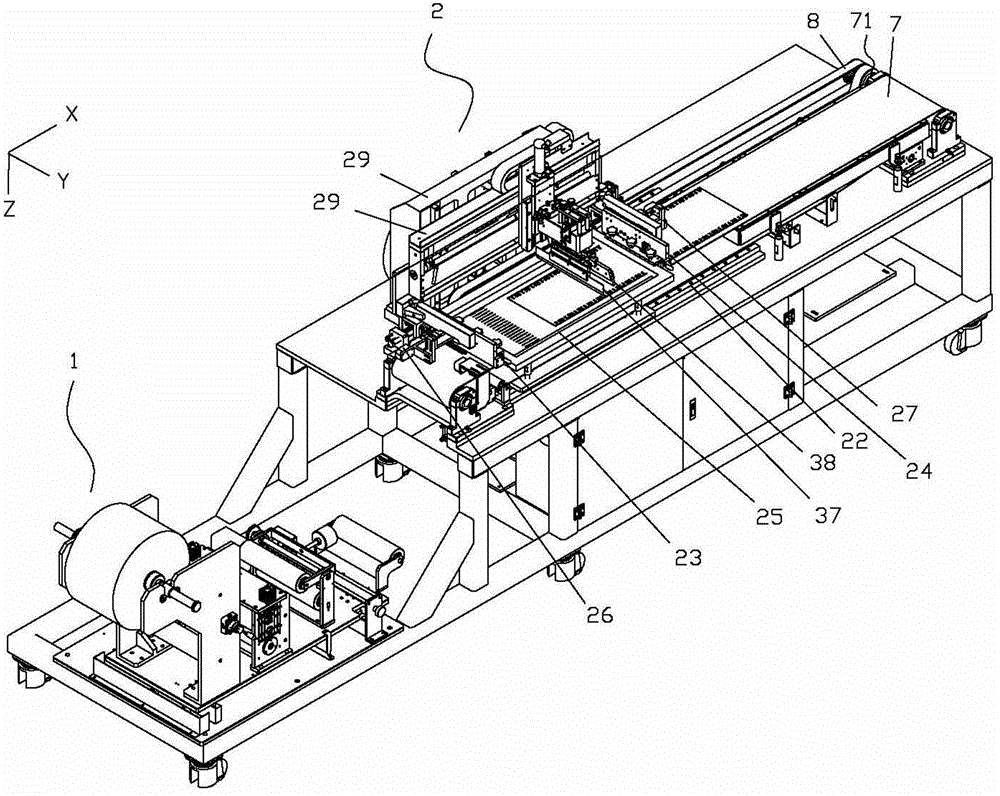

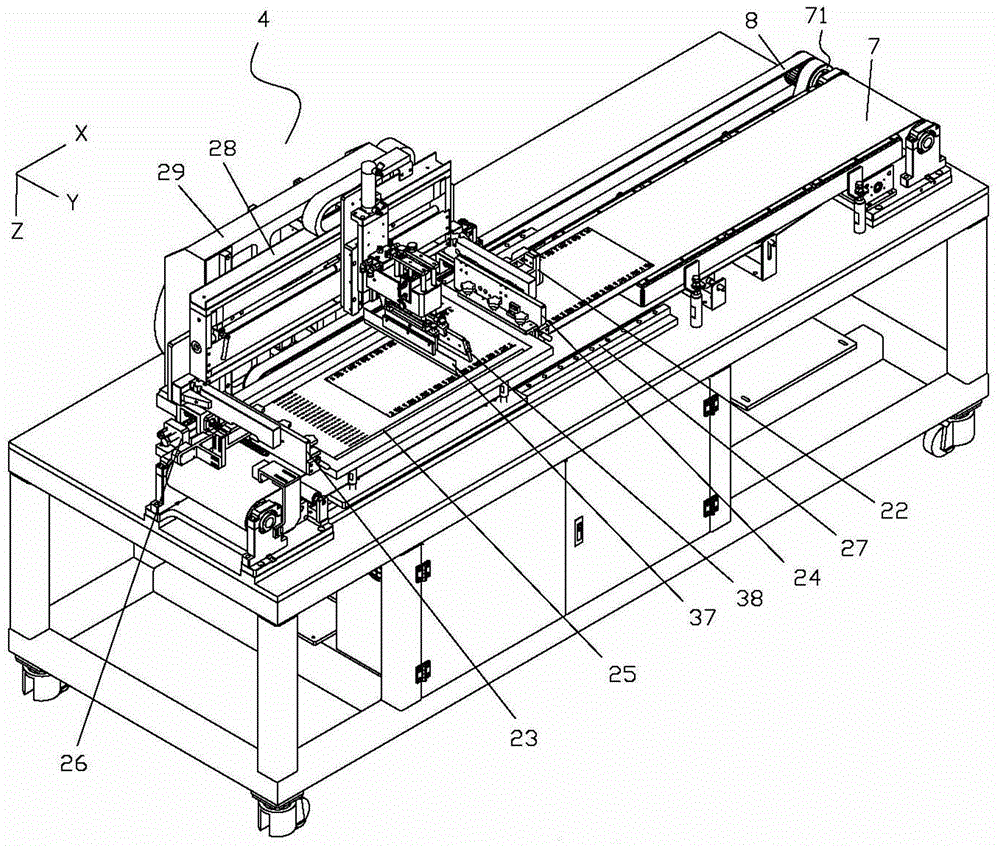

[0046] Such as Figure 1-2 As shown, continuous and uninterrupted screen printing ink lines for FPC substrates, including:

[0047] The screen printing machine 2 at the first position, the oven 3 at the first position, the screen printing machine 4 at the second position and the oven 5 at the second position are arranged in sequence along the X direction; A baking device for drying the printed ink;

[0048] The conveyor belt 7 that conveys the FPC substrate along the X direction, and the FPC substrate 9 is sequentially passed through the screen printing machine 2 at the first position, the oven 3 at the first position, the screen printing machine 4 at the second position, and the oven 5 at the second position ; The FPC base material 9 is in the form of a roll, and is stretched and conveyed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com