Plastic sleeve concrete pile and method thereof for reinforcing soft soil foundation

A technology of plastic casing and concrete pile, which is applied to sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of soil disturbance around the pile, increase construction cost, damage, etc., to increase contact friction and increase construction. cost, the effect of ensuring the quality of the installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

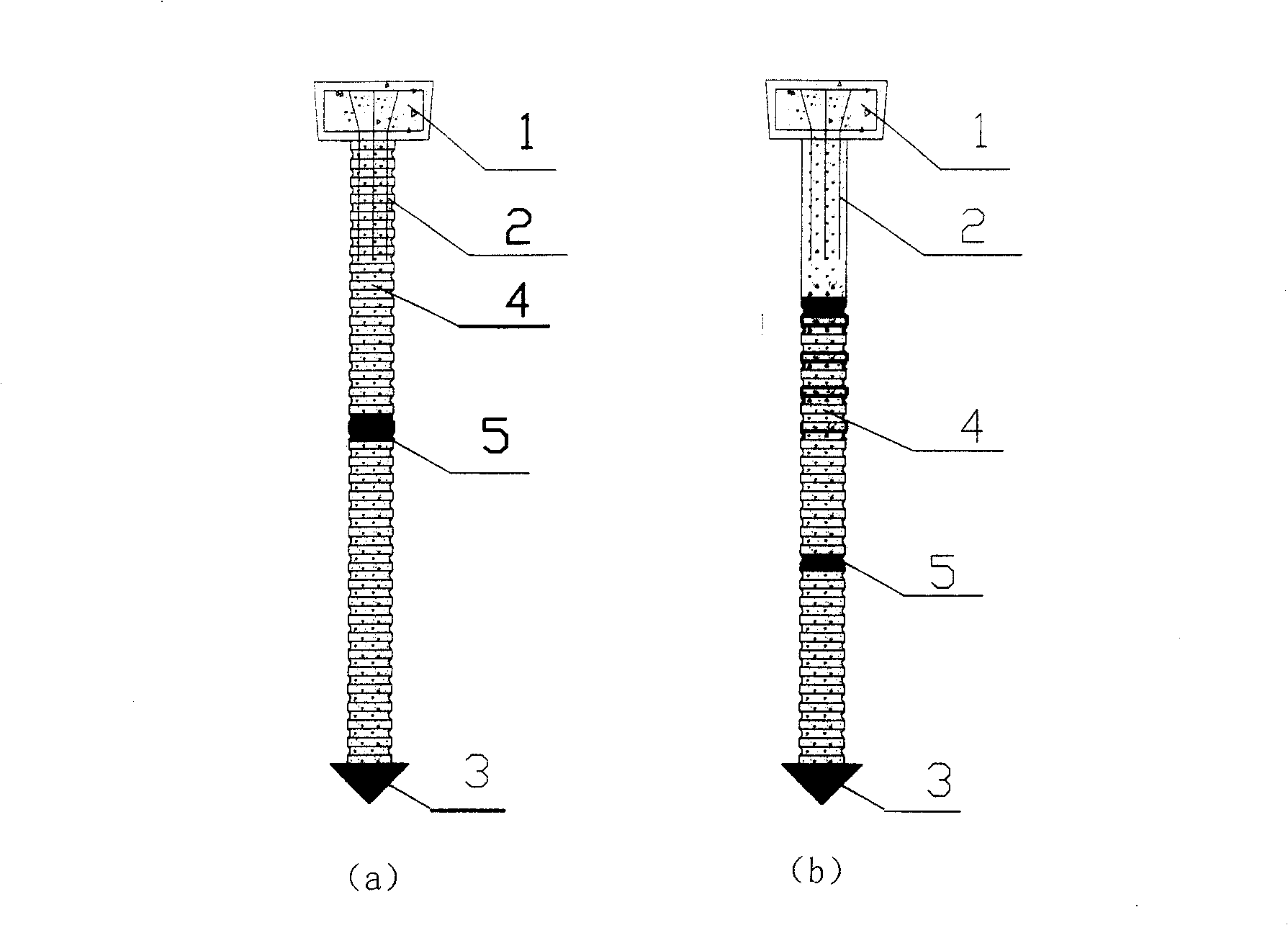

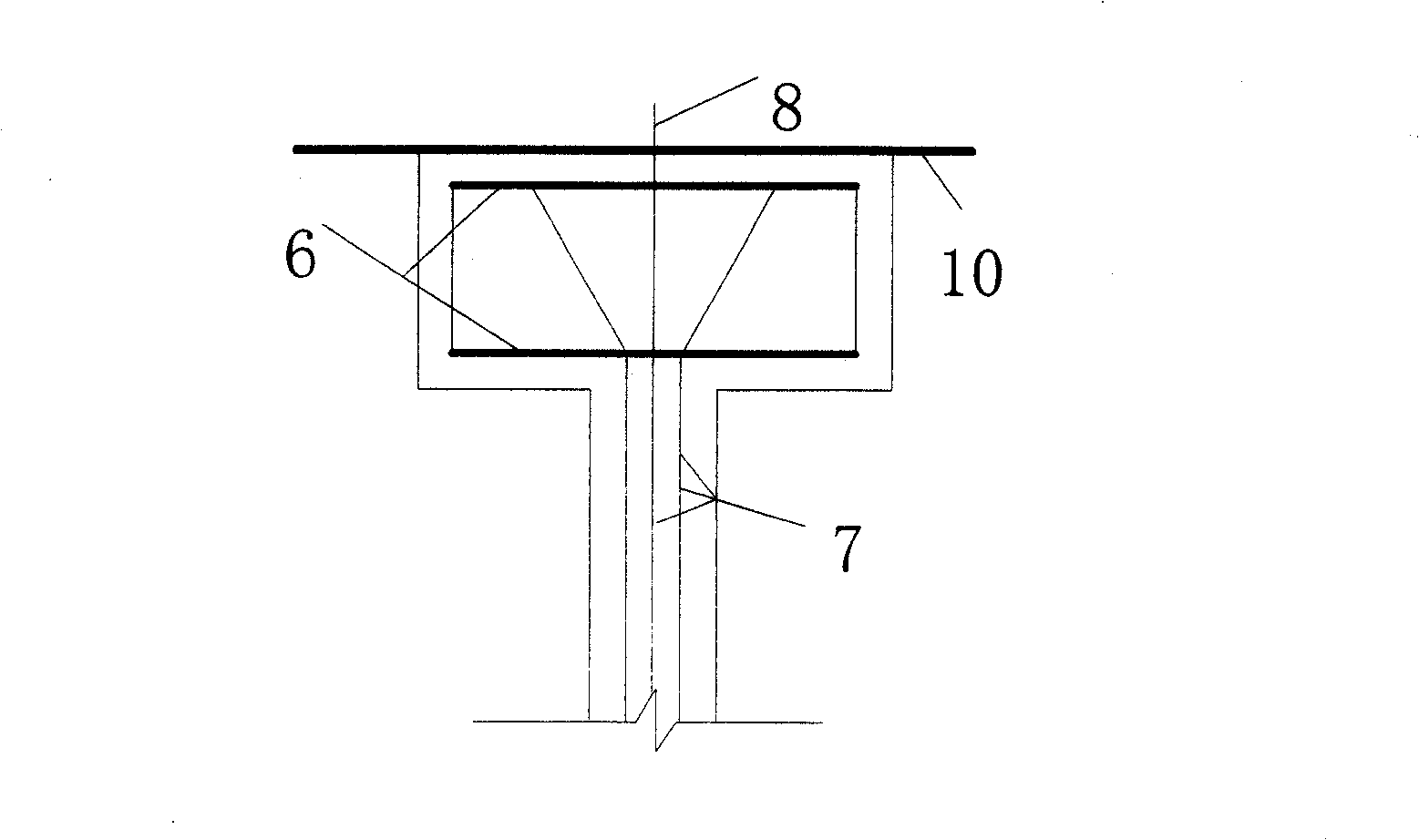

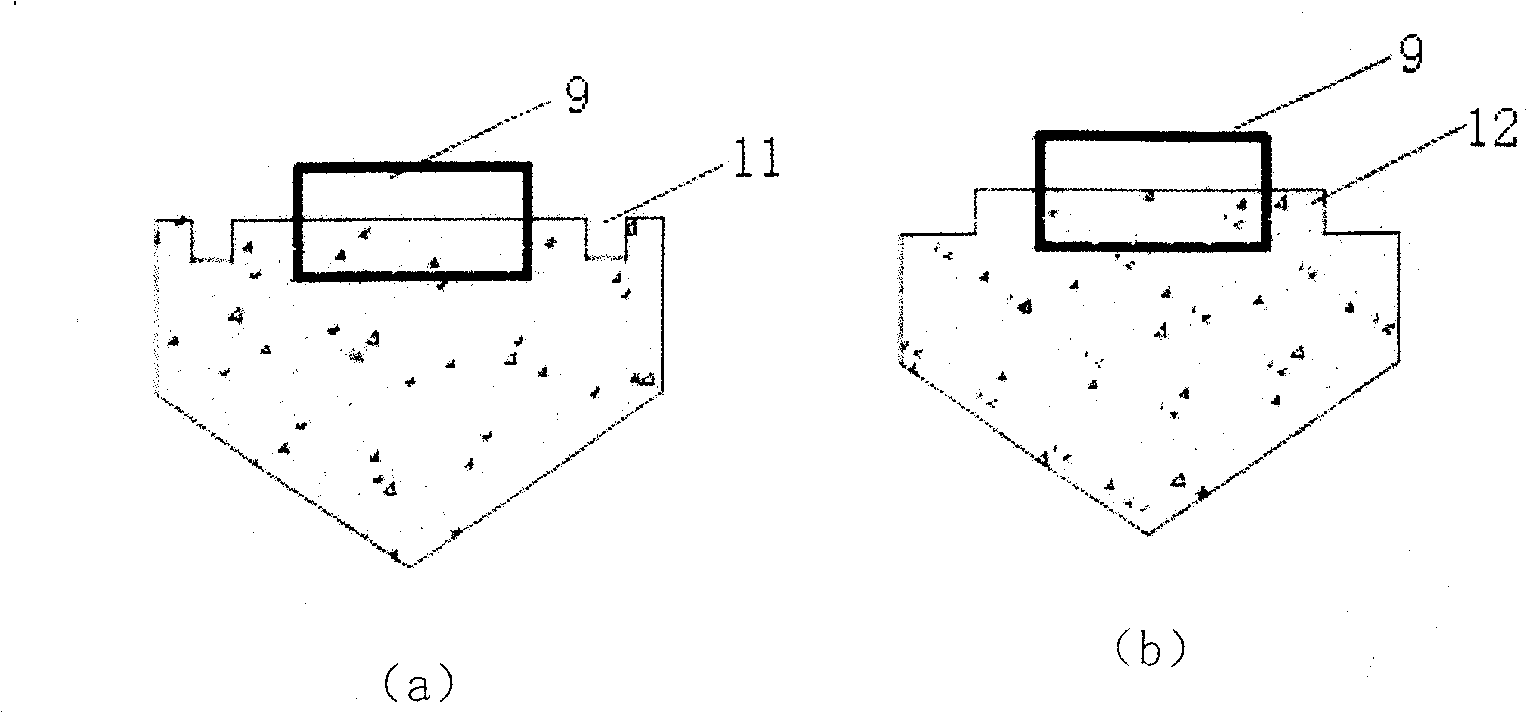

[0039] The pile tip 3 with a concave ring is prefabricated with a specially developed special plastic casing concrete pile tip mold; the casing 2 of PVC material is reasonably selected according to the soil quality parameters, the driving depth, and the pile spacing; the length of each casing is 10 meters, 25 cm in diameter, the pile body is connected by a fully threaded casing figure 1 -(a); Each section of the plastic casing is connected to the design pile with a joint 5 and glued to the design pile with a length of 20 meters; the lower end of the plastic casing 2 is connected to the prefabricated concave ring pile tip 3 The casing plug 9 is connected and glued with PVC adhesive to form a semi-enclosed space with an opening at the upper end of the casing; for the convenience of putting the casing into the immersed pipe, use a plastic casing concrete pile driver to lift the immersed pipe 14 to At a height of 2 meters, pull the plastic sleeve 2 connected to the pile point 3 in...

Embodiment 2

[0041] The pile tip 3 with a stepped platform is prefabricated with the specially developed special plastic casing concrete pile tip mold; the casing 2 of PVC material is reasonably selected according to the soil quality parameters, the driving depth, and the pile spacing; The casing with smooth outer wall 2, the lower section adopts the full threaded casing connection method figure 1 -(b); use joint 5 between each section of plastic casing 2, and be connected to design pile length 20 meters with PVC adhesive glue, fix 4 grouting pipes 13 with iron wire on the periphery of casing 2, plastic The lower end of the casing 2 is connected to the prefabricated casing plug 9 with a stepped platform pile point 3, and glued with PVC adhesive to form a semi-enclosed space with an opening at the upper end of the casing; for convenience, the casing is put into the immersed pipe , use a plastic sleeve concrete pile driver to lift the immersed tube 14 to a height of 2 meters, pull the plasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com