Control system for stackable multi-color-head three-dimensional printer capable of realizing precision printing

A 3D and control system technology, applied in the control system field of stacked colorful 3D 3D printers, can solve problems such as unusable and low mechanical strength, avoid the trouble of detection and replacement, reduce processing costs, enhance control accuracy and reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment one structure is as follows:

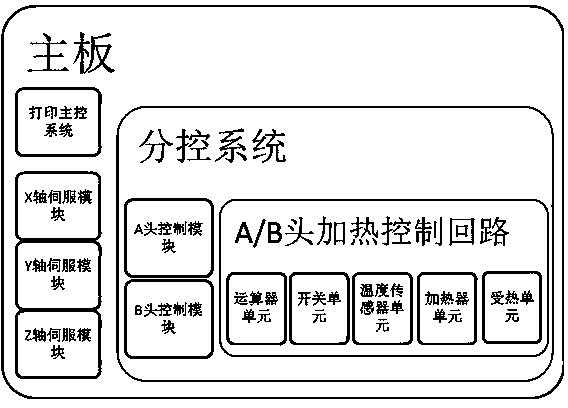

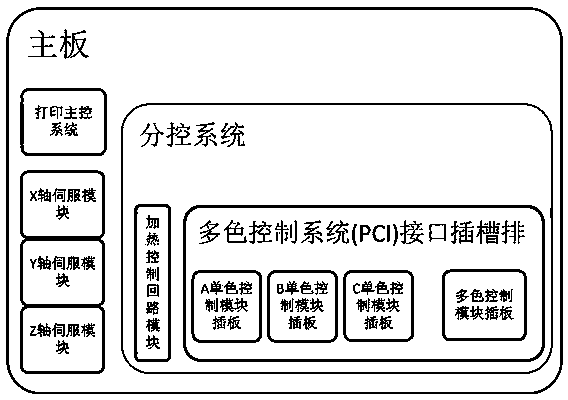

[0035] See image 3 , 4 , the structure of the control main board includes the printing main control system, the X-axis servo module, the Y-axis servo module, the Z-axis servo module and the sub-control system in the prior art. The heating control circuit module is set in the sub-control system. The operating procedure of the heating system control circuit is the same as that of the existing technology. Board structure; connect the multi-color control system (PCI) interface slot row at the end of the sub-control system interface control circuit of the main board, and set more than three single-color control module boards in discrete modular packaging. Each single-color control module board is respectively installed on the slot row to ensure that the length of the signal transmission path is equal. Using the connection method of plug board and slot can realize the technical index requirements of matching symmetry of each contr...

Embodiment 2

[0045] The structure of the second embodiment is as follows (suspended walking flexible connection print head):

[0046] See Figure 9 , 10 , the difference between embodiment two and embodiment one is described in detail as follows:

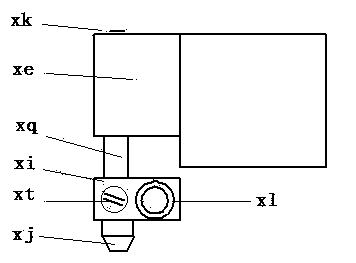

[0047] The three-color printing head is equipped with three wire feeding pumps e, and the three wire feeding pumps e are arranged on the sliding base x, and a walking bracket h is installed, and a linear bearing g is installed on the walking bracket h, and is suspended under the walking bracket h The trapezoidal frame z is connected in the same way, the sliding base x is placed in the trapezoidal frame z, the bottom of the four inner inclined planes z-1 of the trapezoidal frame z is slidingly fitted with the four sides of the rectangular sliding base, and the sliding fit accuracy limits the horizontal displacement accuracy to ±0.01 mm, to ensure that the sliding base can be displaced in the vertical direction; the three wire feed pumps e and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com