Cloth conveyor of ink-jetting printing machine

An inkjet printing machine and cloth feeding technology, which is applied to printing devices, printing, typewriters, etc., can solve the problems of large differences in cloth deviation, increased costs, and serious cloth deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

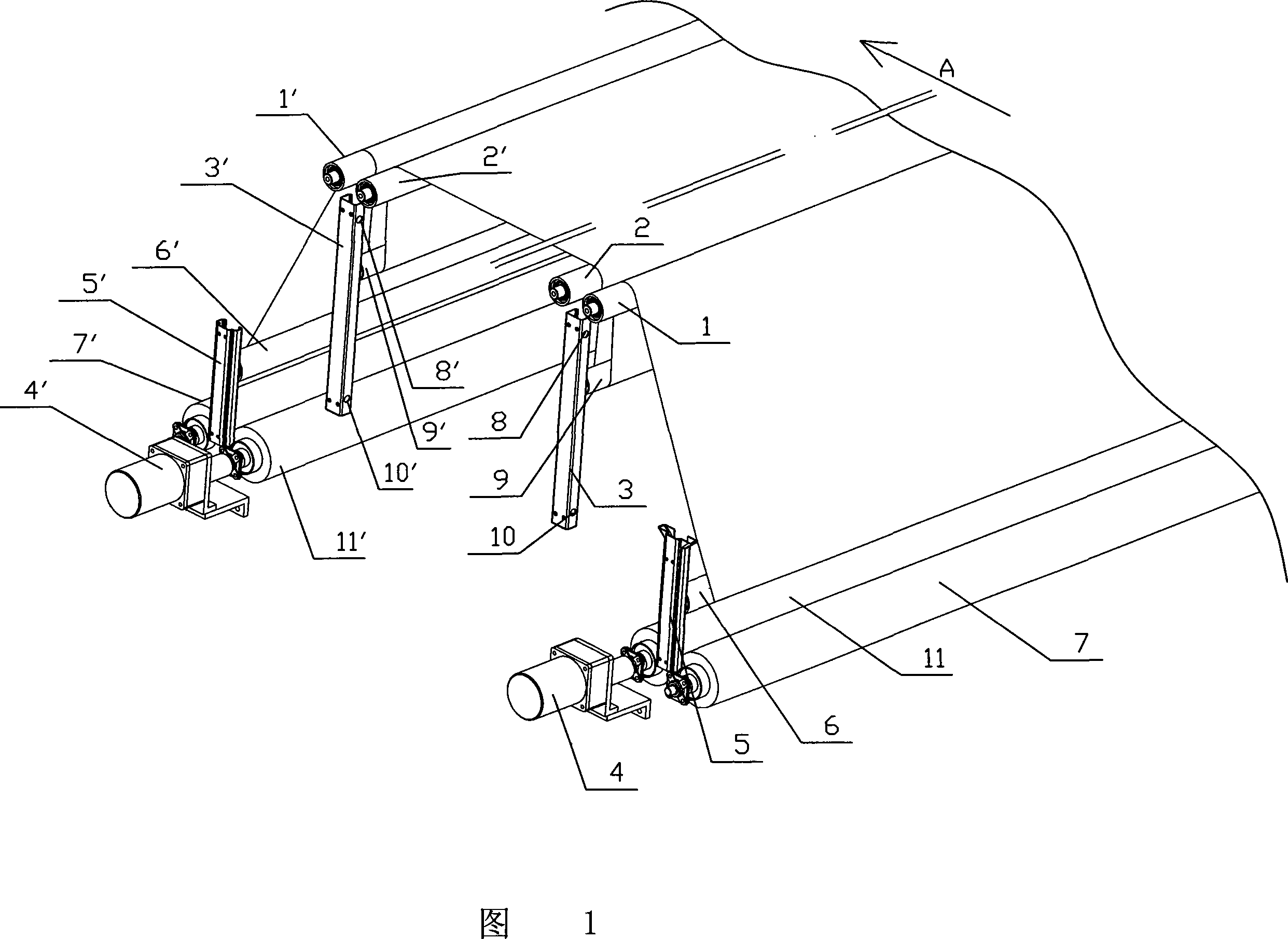

[0016] Referring to Figure 1, the cloth feeding and collecting device of the inkjet printing machine of the present invention includes a cloth feeding mechanism and a cloth collecting mechanism. A cloth feeding tension mechanism and a cloth collecting tension mechanism are provided between the cloth feeding mechanism and the cloth collecting mechanism. After the cloth mechanism is led out, it enters the cloth feeding tension mechanism, and then enters the printing working area of the printing machine. After the printing is completed, the cloth enters the cloth collecting tension mechanism, and finally enters the cloth collecting mechanism. The travel of the cloth in the printing work area can be driven by a guide belt or other travel power devices in the prior art. The printing work area and the guide belt that drives the cloth to travel are not shown in Figure 1, that is, the part omitted by the dotted line.

[0017] The cloth feeding tension mechanism includes two cloth feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com