Support structure design method for complex part SLM forming

A technology of complex parts and support structures, which is applied in the field of support structure design and support structure design for SLM molding of complex parts, which can solve the problems of high processing cost, waste of manpower and material resources of SLM process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0035] The purpose of the present invention is to provide a more systematic design method for complex parts support, so that the quality of the printed parts is as high as possible, and the number of printing times is as few as possible, so as to reduce the processing cost.

[0036] The technical solution adopted to solve the above problems: to provide a support structure design method that satisfies the SLM forming of complex parts, including the following steps:

[0037] (1) Through the design pre-experiment, obtain the drape angle, hole, wall thickness, sharp corner, cylinder and other ultimate forming dimensions, support strength and removal difficulty involved in the printing under the forming process;

[0038] (2) Optimize the placement angle to avoid large overhangs during printing. For important processing surfaces, it should be placed on the top, and thin walls and round holes should be formed in the vertical direction;

[0039] (3) According to the structural characteristics ...

Embodiment 1

[0046] The content of the present invention will be described in detail in the following section with reference to the accompanying drawings.

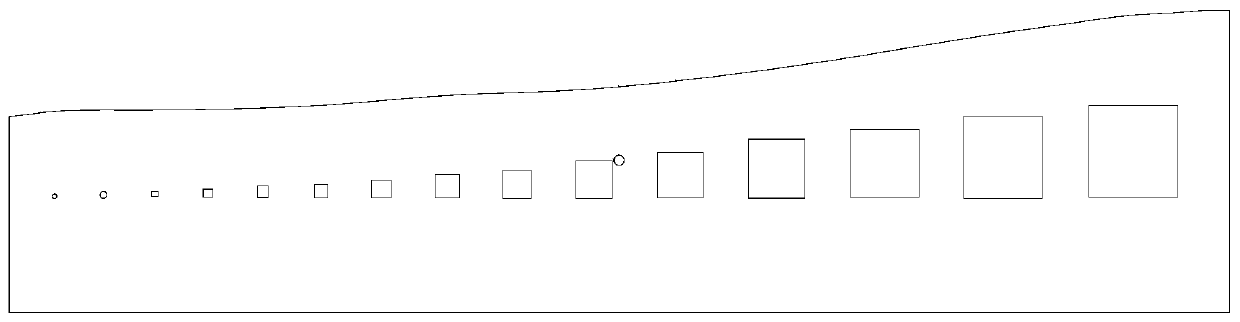

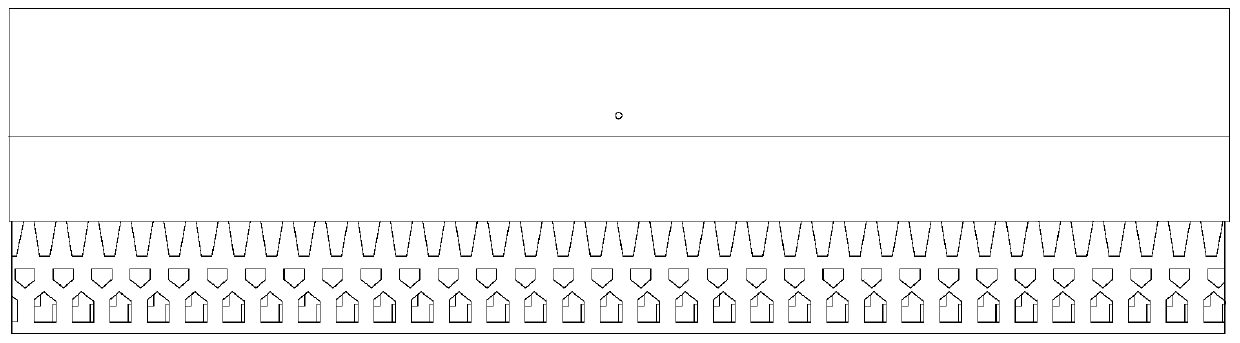

[0047] Through the pre-experiment, we must first understand the equipment's ability to process complex structural features such as overhanging planes, holes, wall thickness, sharp corners, and cylinders. Therefore, it is necessary to obtain the printed parts under the molding process in modeling software such as UG and Pro-E. Three-dimensional models of these structural features with different parameters involved, such as figure 1 As shown, the model is imported into Magics software in stl. format. Generally, the overhang angle can be set to 30~45°, the hole is The wall thickness is 0.1~1mm, the sharp angle is 5~30°, the cylinder is In addition, it is also necessary to set up a three-dimensional model for strength research under different support parameters (usually a long strip specimen with an aspect ratio greater than 3), such as fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com