Cloth stentering mechanism, cloth stentering method and cloth feeding device having stentering mechanism

A technology of cloth feeding device and cloth, which is applied in the direction of printing device, printing, etc., can solve the problems of affecting the printing effect, reducing the service life of the nozzle, and the expansion effect of elastic cloth and knitted cloth is not ideal, so as to ensure the printing quality and protect the no damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

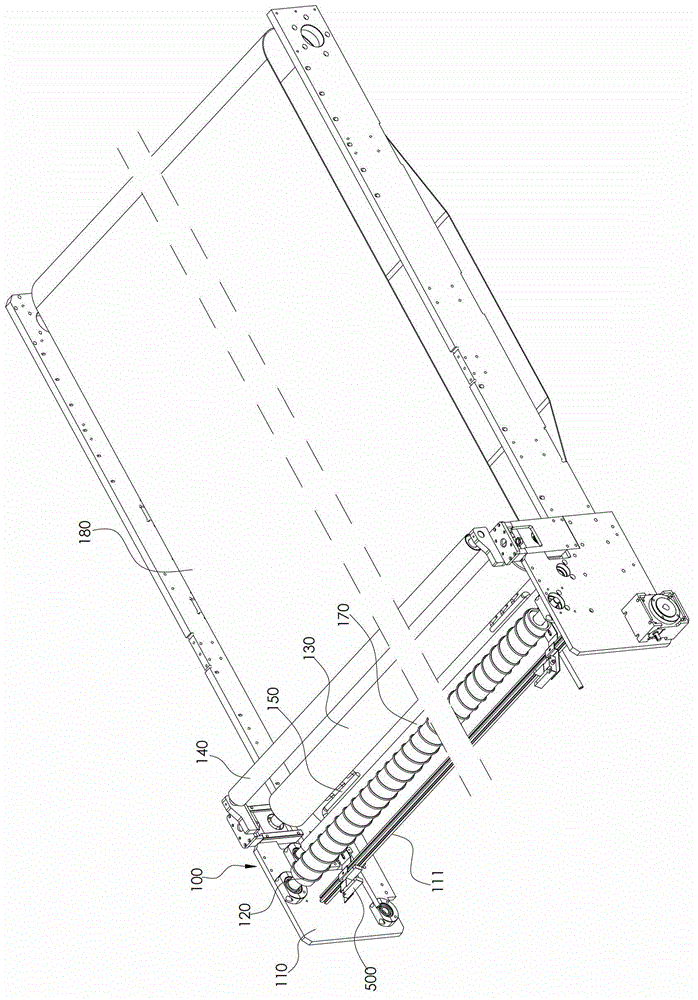

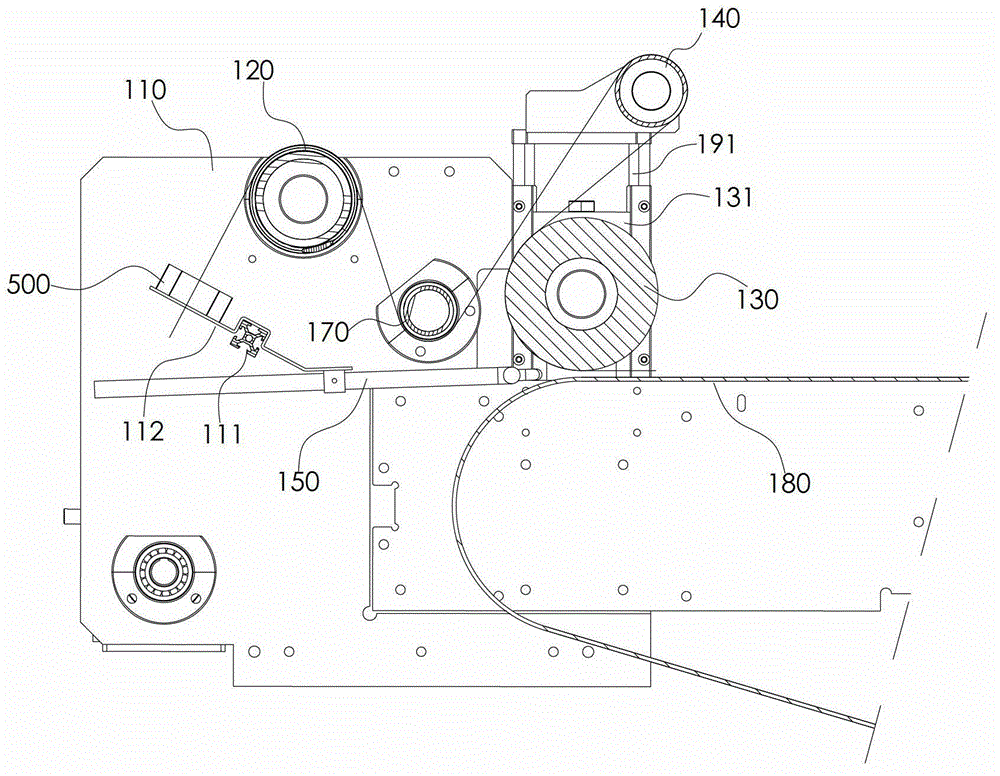

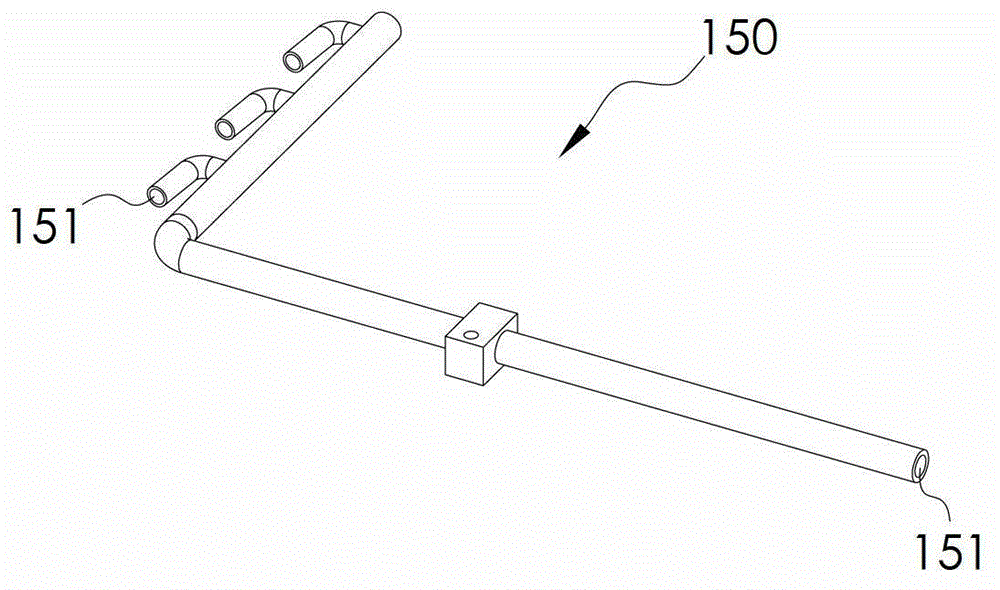

[0049] see figure 1 , 2 3. The cloth expanding mechanism 100 of the present invention includes a fixed plate 110 and an expanding roller 120 pivotally connected to the fixed plate 110 and parallel to each other, a cloth pressing roller 130, a cloth resting roller 140 and a cloth guide roller 170, and the cloth pressing roller A guide belt 180 is arranged below 130, and the cloth is wound around the spreader roller 120, the cloth guide roller 170, the cloth resting roller 140, and the cloth pressing roller 130 sequentially from the side of the spreading roller 120, and is finally pressed on the cloth pressing roller 130. Between the roller 130 and the guide belt 180 . An air blowing pipe 150 is installed on the fixed plate 110 , the air inlet 151 of the air blowing pipe 150 is connected with an air delivery device, and its air outlet 152 is located bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com