Powder duster recycling and circulating system

A technology of circulation system and duster, which is applied in printing presses, gold powder printing, general parts of printing machinery, etc., can solve the problems of easy clogging of printing powder, unreasonable air distribution of suction fans, high noise, etc., and achieve smooth flow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings of the description.

[0024] In view of the components of the duster of the recycling system of the present invention, the present invention will be described in detail below in conjunction with the description of the duster.

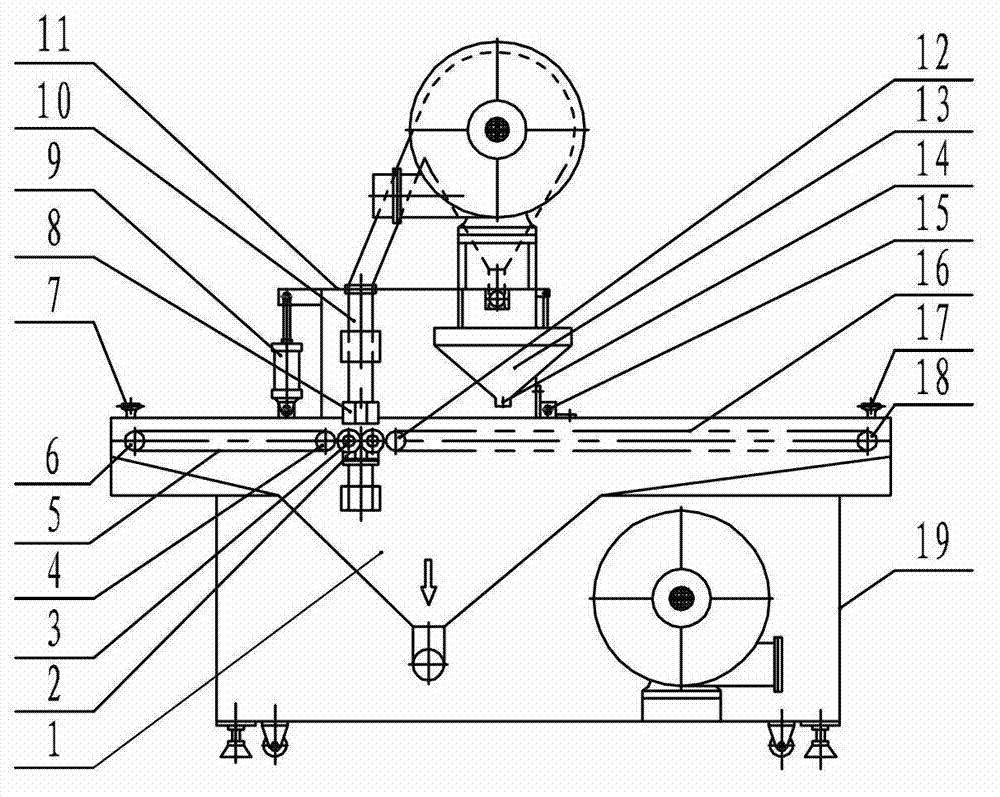

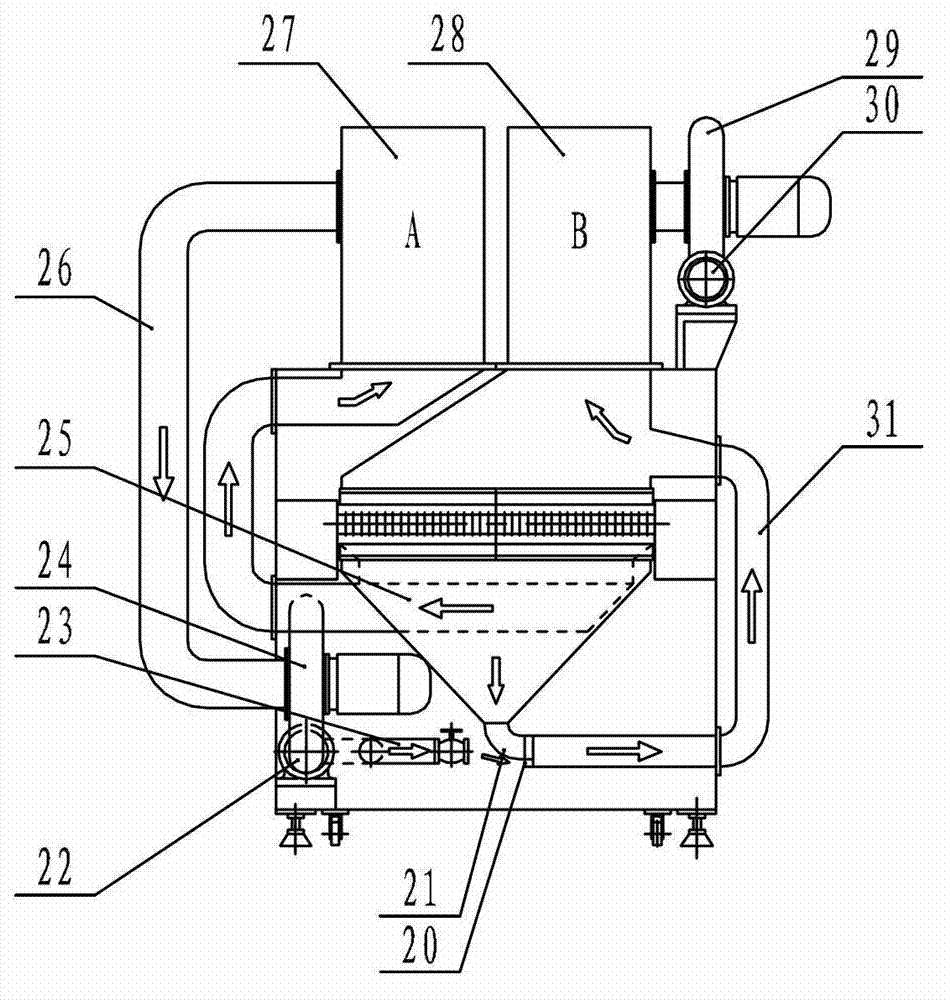

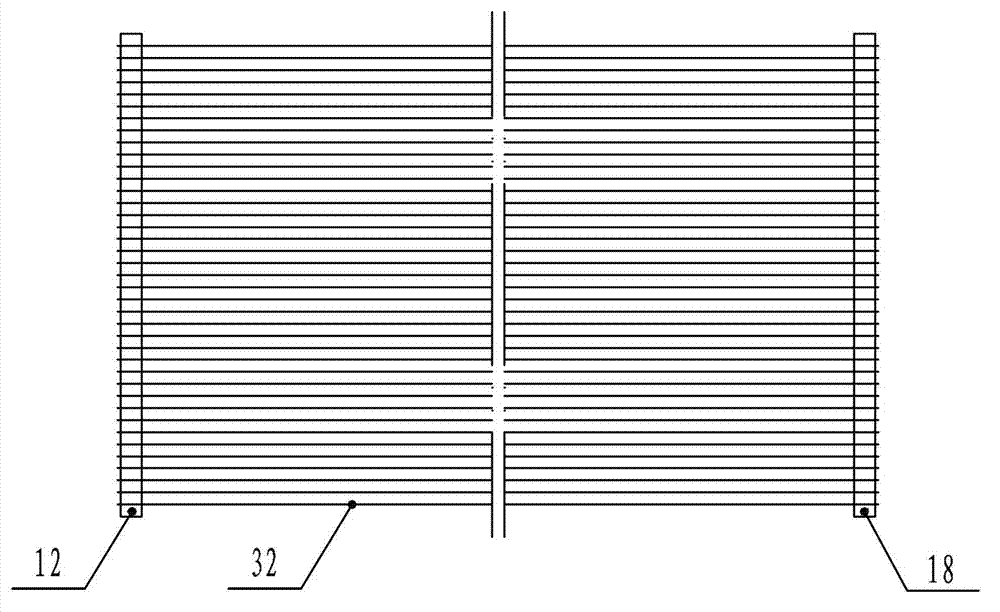

[0025] Such as figure 1 , 2 The shown powder spreader comprises the front conveyer belt 16 positioned on the same plane, the rear conveyer belt 5 and the paper support wheel 3 (shown as two) between the two, and the upper side of the paper support wheel 3 is set to face The last powder suction port 8 of the supporting paper wheel, the upper powder suction port 8 links to each other with the air powder separator B28 through the upper powder suction pipeline 10, and the air powder separator B28 is connected with a suction fan B29; Facing the lower powder suction port 2 of the support wheel, the lower powder suction port 2 is connected to the air po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com