Film stamping machine capable of automatically rolling materials

A roll film and bronzing machine technology, which is applied to printing machines, gold powder printing, rotary printing machines, etc., can solve the problems of difficult finishing and soft items such as films, and achieve the effect of safe processing and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

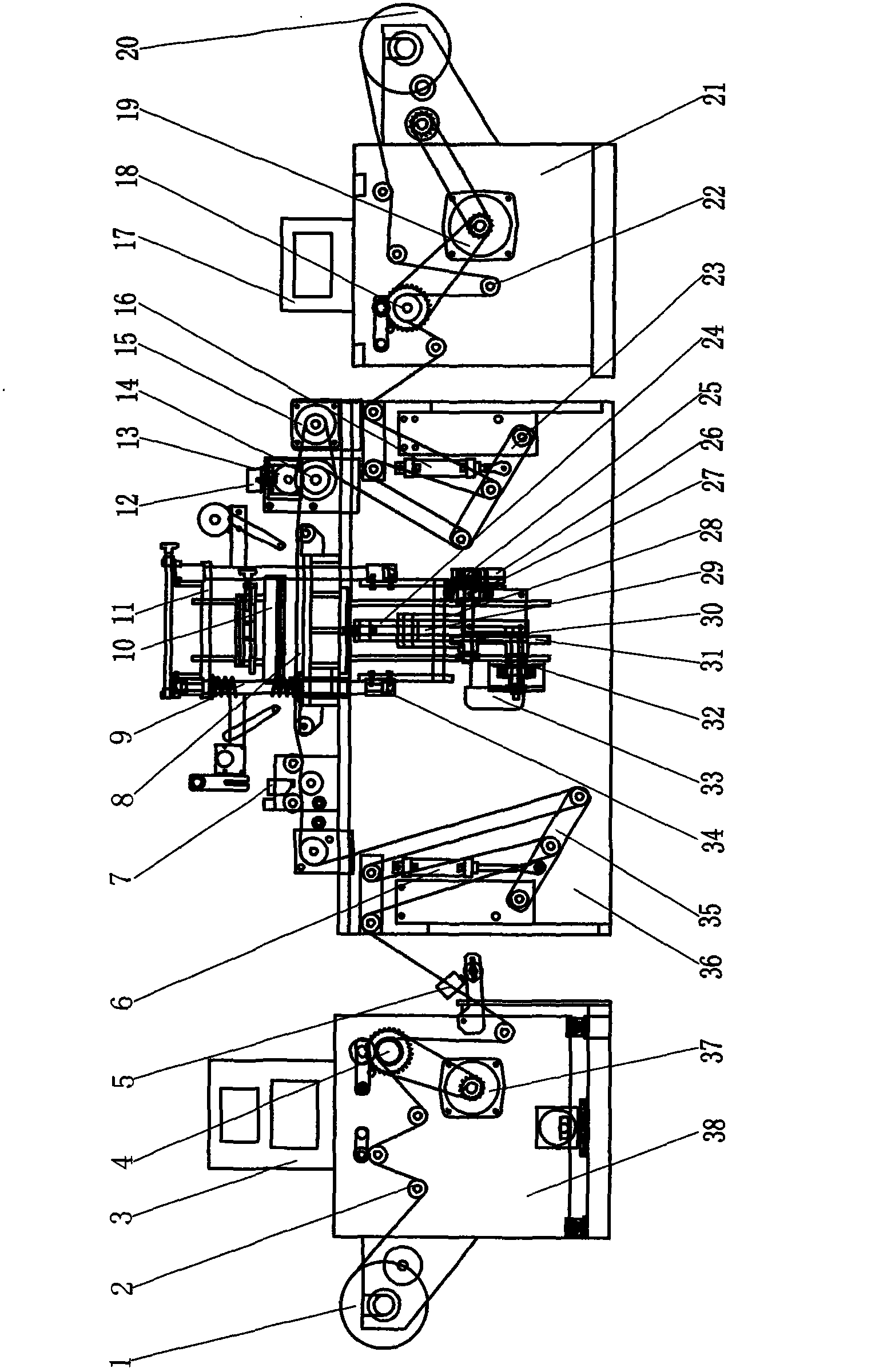

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

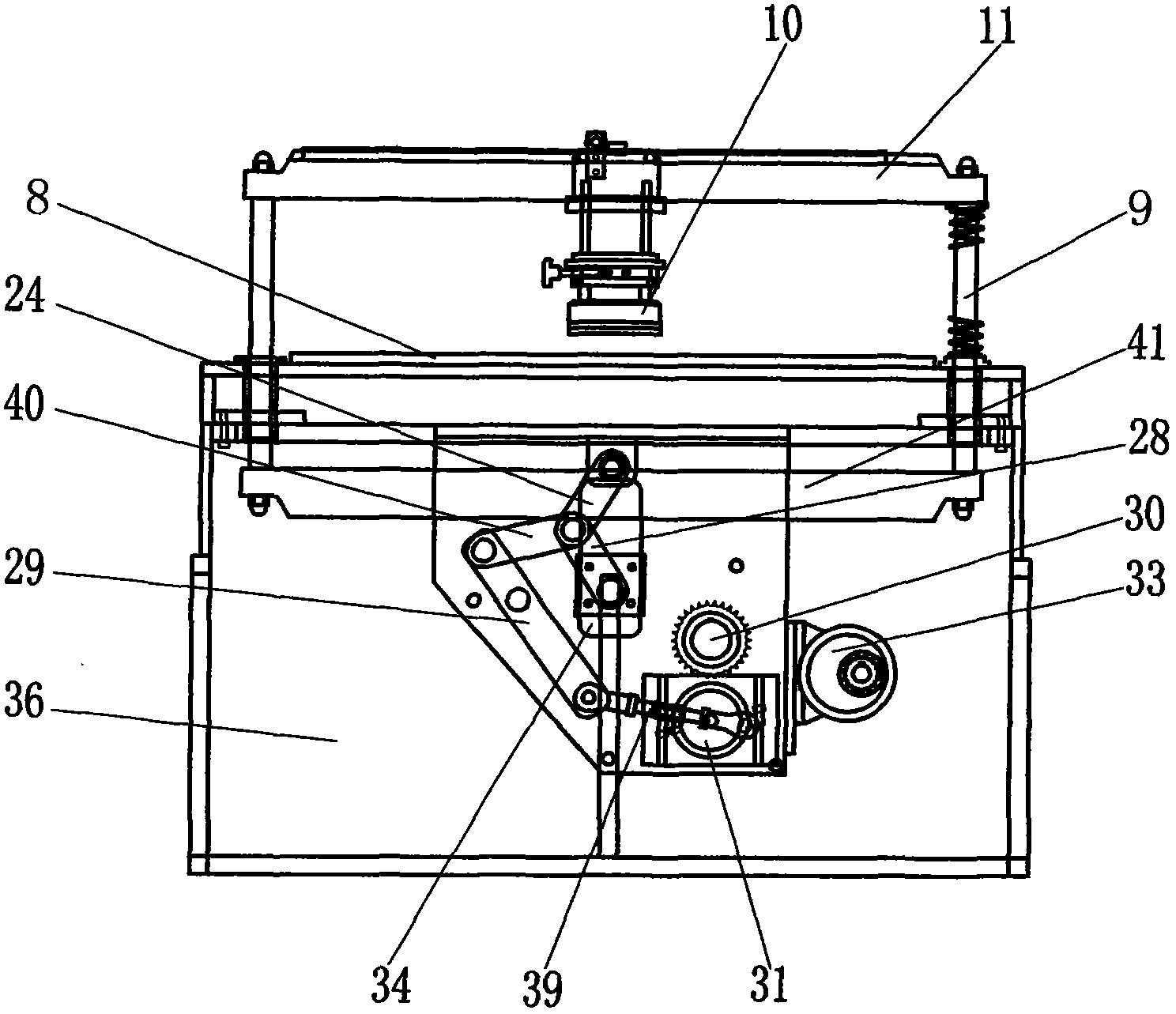

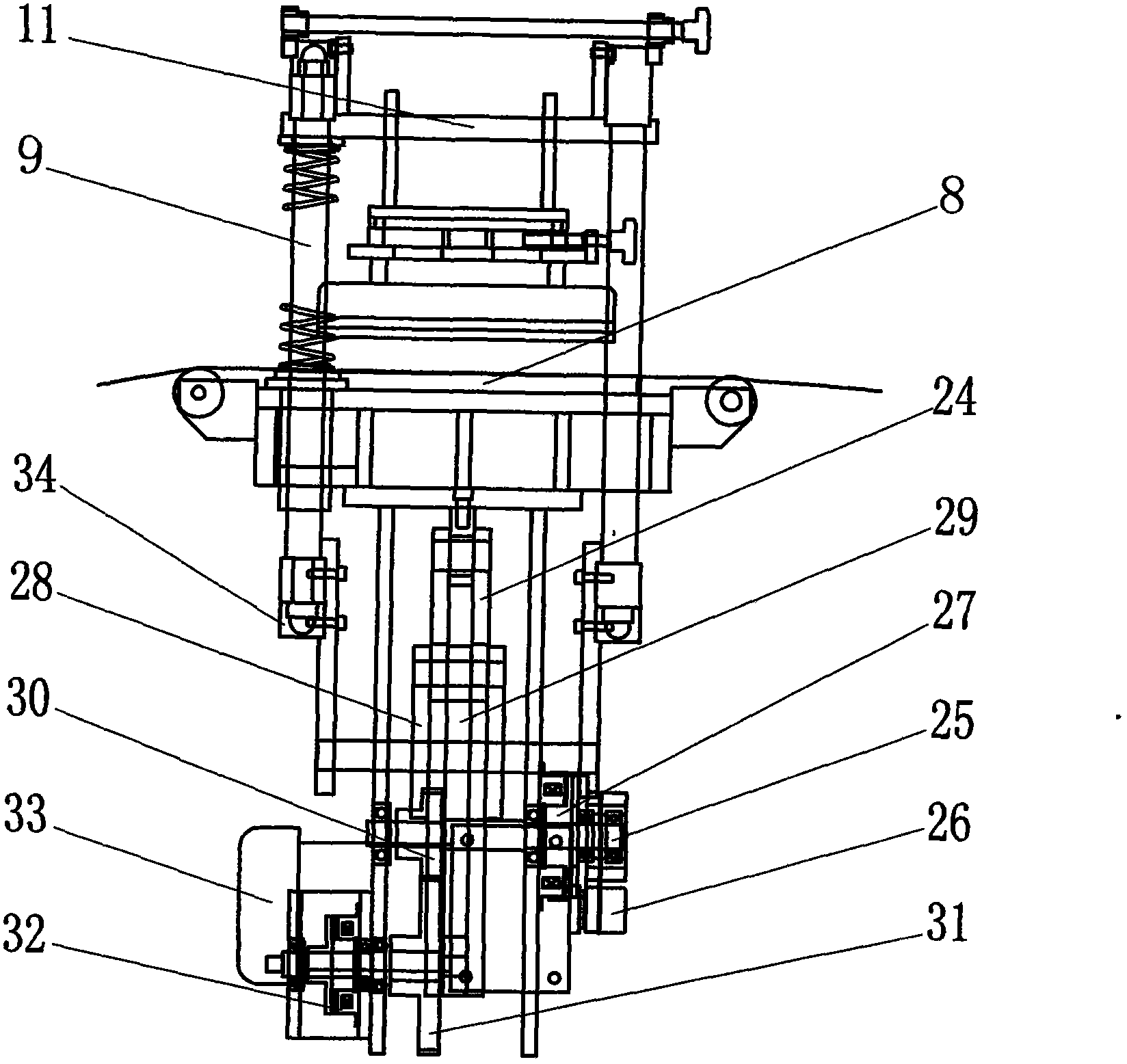

[0015] As shown in the figure, the drive motor 33 is housed in the bottom case 36, the main sprocket 26 is arranged on the right shaft of the drive motor 33, the sprocket shaft 25 is connected above the main sprocket 26, and the drive electromagnetic clutch is equipped on the sprocket shaft 25. 27. The left end of the sprocket shaft 25 is equipped with a pinion 30, and the underside of the pinion 30 is equipped with a meshing driving gear 31. The driving gear 31 is coaxially equipped with a driving electromagnetic brake 32, and the driving gear 31 is equipped with an eccentrically connected steering link. 39, the front end of the adjustment connecting rod 39 is connected with the driving connecting rod 29 ( figure 2 ), the middle part of the drive link 29 is connected with the bottom box 36 by the shaft, the upper end of the drive link 29 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com