Thermoprinting equipment and thermoprinting method based on ink-jet printing device

An inkjet printing and equipment technology, applied in the field of printing decoration technology, can solve the problems of affecting the color and gloss of hot stamping graphics, reducing the aesthetics of products, and the diffuse reflection of cold stamping foils, so as to improve the aesthetics, facilitate separation, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

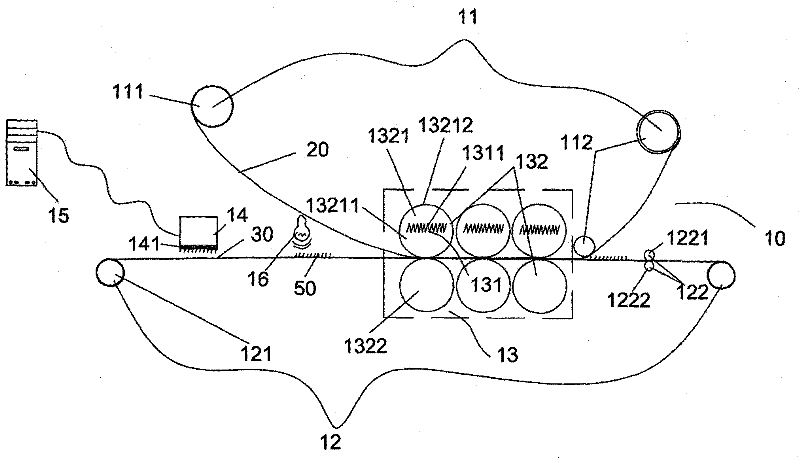

[0036] Such as figure 1 As shown, a hot stamping equipment 10 based on an inkjet printing device includes a hot stamping foil conveying device 11 for conveying a hot stamping foil, a substrate conveying device 12 for conveying a substrate, and a hot stamping foil 20 for The embossing device 13 bonded together with the substrate 30, the hot stamping foil 20 includes a plastic film layer, a separation layer, an imaging layer and a metallized layer from top to bottom, and the hot stamping foil conveying device 11 includes a roll feeding Roller 111 and take-up roller 112, described substrate conveying device 12 comprises the feeding mechanism 121 that is used to send substrate and hot stamping foil to embossing device and is used for clamping substrate to let substrate 30 and hot stamping foil 20 separated separation mechanism 122, the separation mechanism 122 includes an upper pinch roller 1221 and a lower pinch roller 1222, the upper pinch roller 1221 and the lower pinch roller ...

Embodiment 2

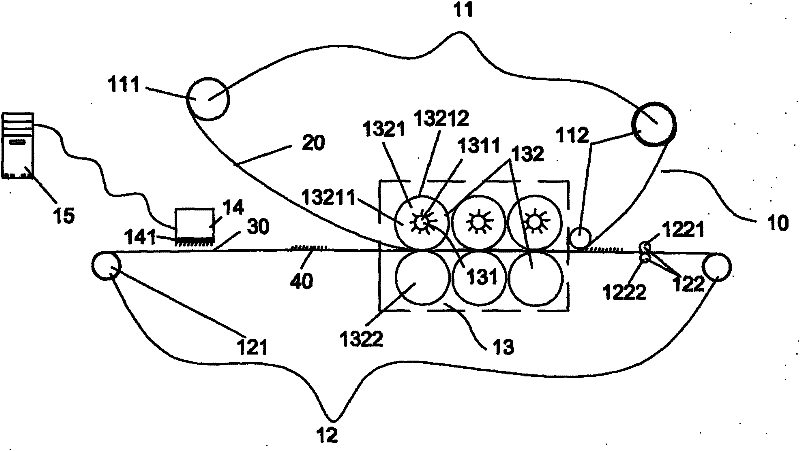

[0044] Such as image 3 As shown, a hot stamping device 10 based on an inkjet printing device includes a hot stamping foil conveying device 11 for conveying a hot stamping foil, a substrate conveying device 12 for conveying a substrate, and a stamping foil and a substrate conveying device 12 for An embossing device 13 in which substrates are bonded together. The hot stamping foil includes a plastic film layer, a separation layer, an imaging layer and a metallization layer from top to bottom. The hot stamping foil conveying device 11 includes a roll feed roller 111 and a Take-up roller 112, the substrate conveying device 12 includes a feeding mechanism 121 for feeding the substrate and hot stamping foil to the embossing device and a separation mechanism for clamping the substrate to separate the substrate from the hot stamping foil 122, the separation mechanism 122 includes an upper pinch roller 1221 and a lower pinch roller 1222, the upper pinch roller 1221 and the lower pinch...

Embodiment 3

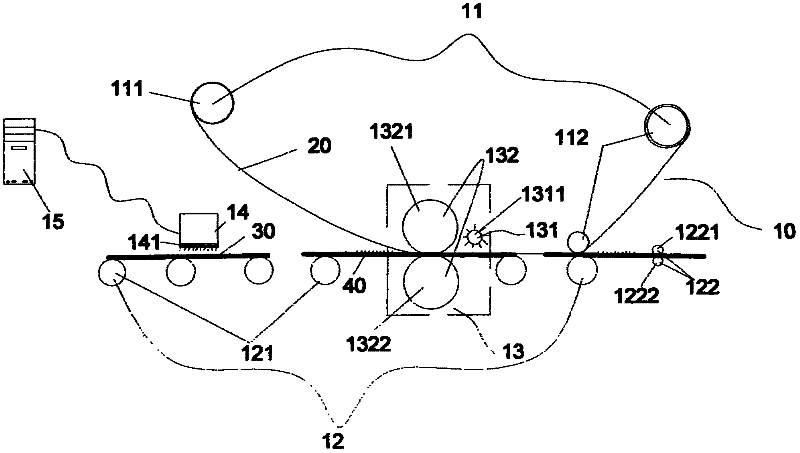

[0051] Such as Figure 5 As shown, a hot stamping device 10 based on an inkjet printing device includes a hot stamping foil conveying device 11 for conveying a hot stamping foil, a substrate conveying device 12 for conveying a substrate, and a stamping foil and a substrate conveying device 12 for An embossing device 13 in which substrates are bonded together. The hot stamping foil includes a plastic film layer, a separation layer, an imaging layer and a metallization layer from top to bottom. The hot stamping foil conveying device 11 includes a roll feed roller 111 and a Take-up roller 112, the substrate conveying device 12 includes a feeding mechanism 121 for feeding the substrate and hot stamping foil to the embossing device and a separation mechanism for clamping the substrate to separate the substrate from the hot stamping foil 122, the separation mechanism 122 includes an upper pinch roller 1221 and a lower pinch roller 1222, the upper pinch roller 1221 and the lower pinc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com