Fully-automatic shoe material stamping machine

A bronzing machine, fully automatic technology, used in printing machines, gold powder printing, rotary printing machines and other directions, can solve the problems of high labor intensity, many staff, low work efficiency, etc., to improve the material turnover rate, high degree of automation , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific examples.

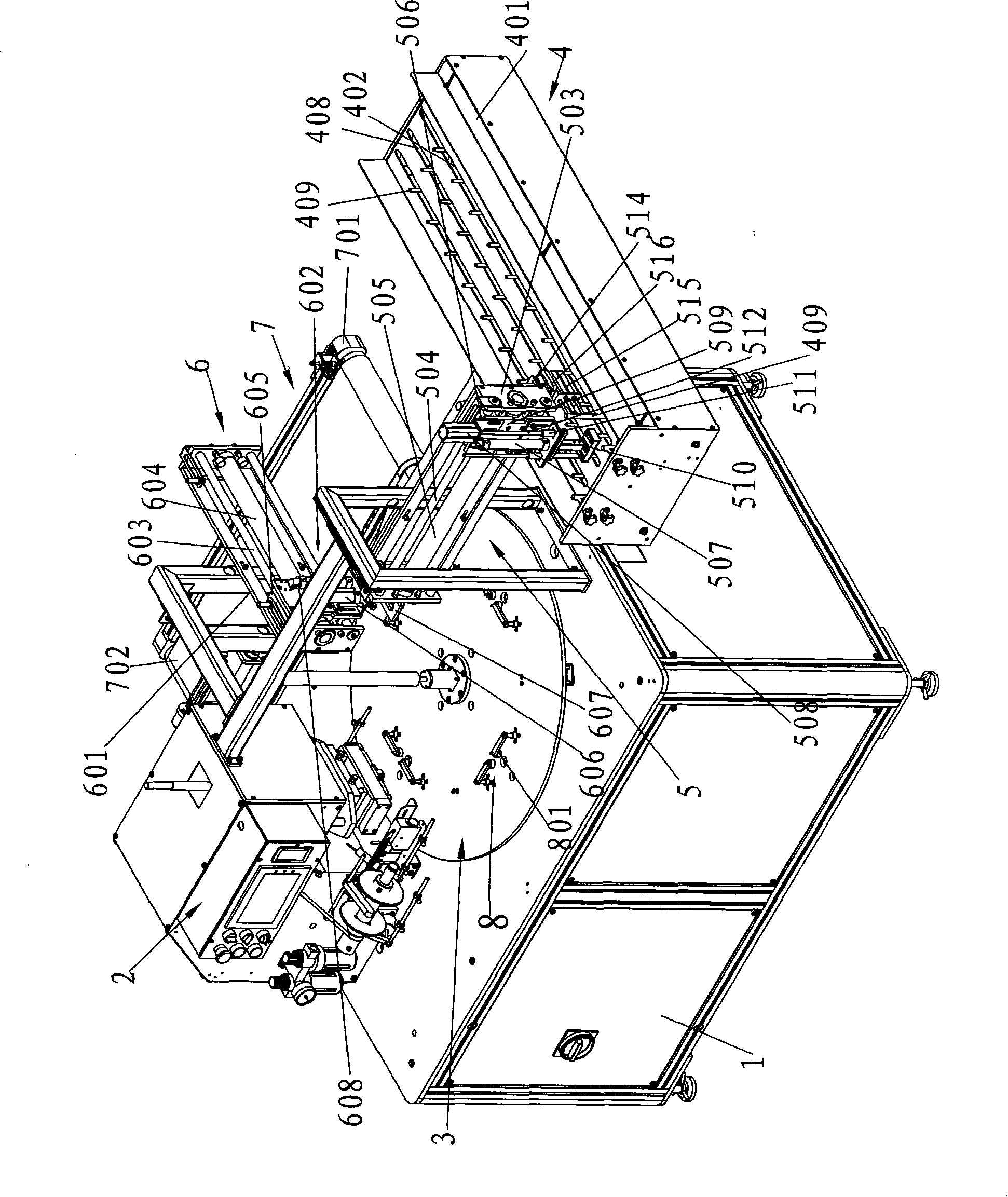

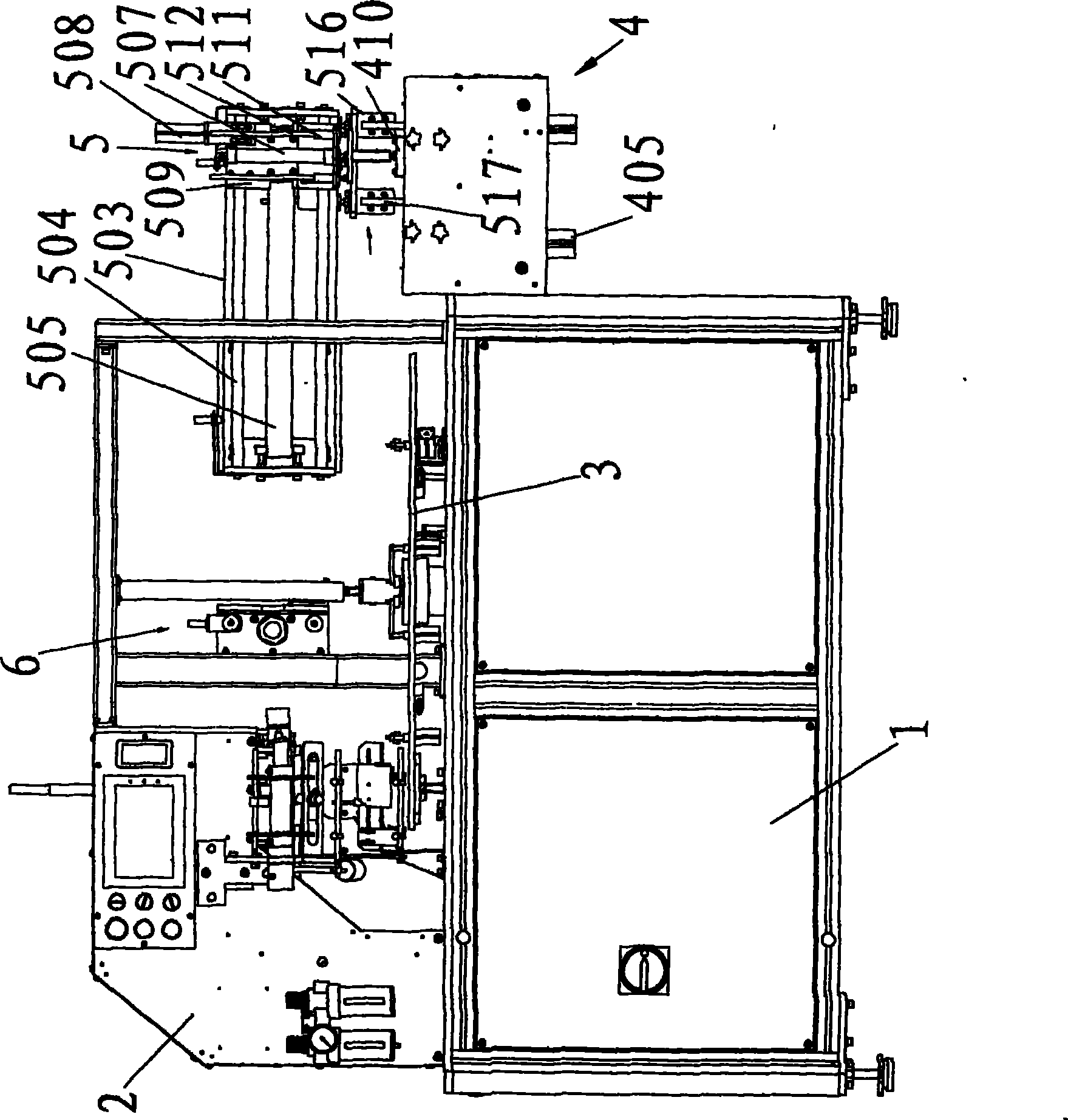

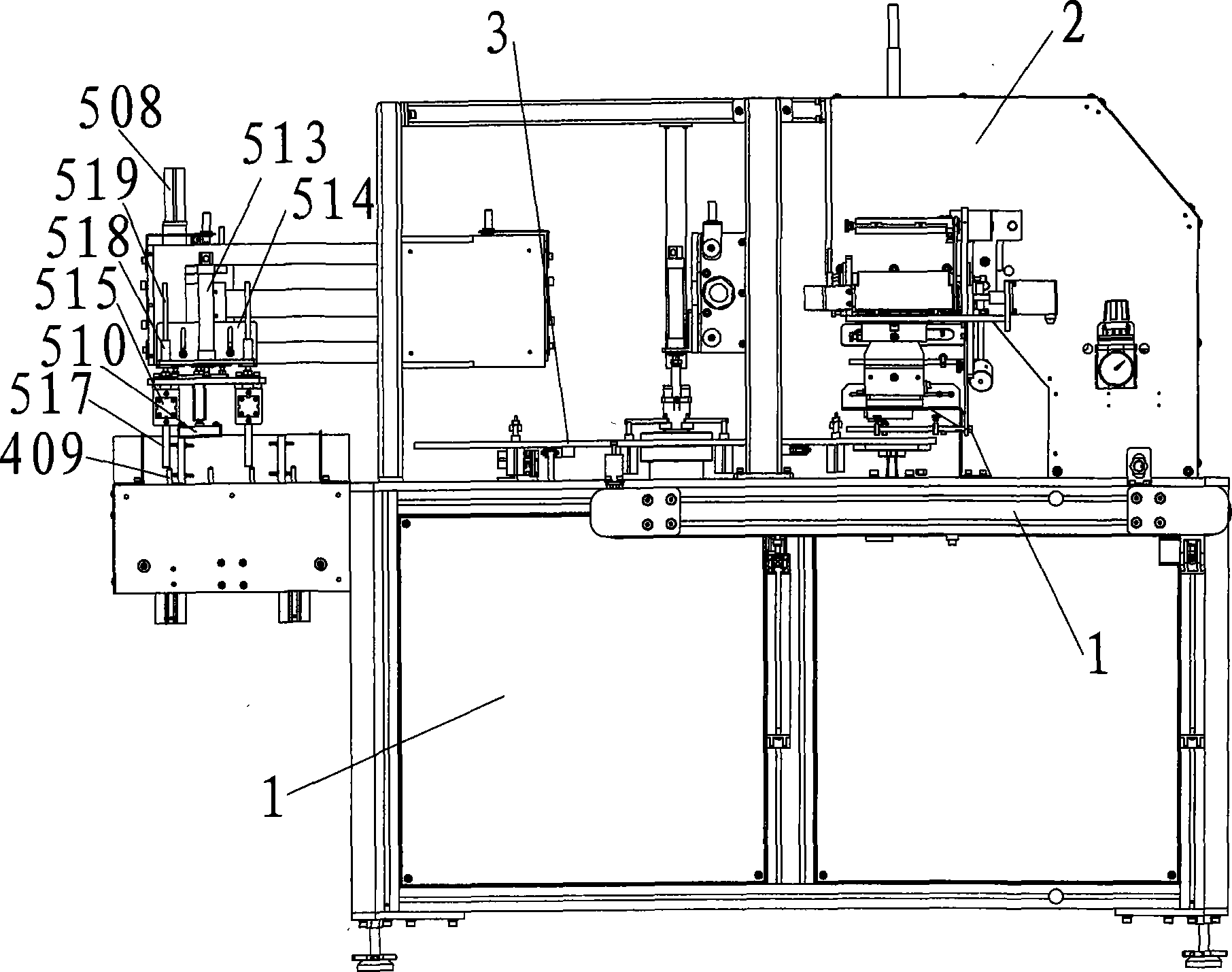

[0020] See attached figure 1 to attach Figure 7 As shown, the fully automatic shoe material hot stamping machine described in this embodiment includes a machine case 1 and a hot stamping mechanism 2, a multi-station turntable mechanism 3, a feeding platform 4, and a feeding mechanism respectively installed on the casing 1. 5. The unloading mechanism 6 and the conveying line 7, wherein the multi-station turntable mechanism 3 described in this embodiment is a four-station turntable mechanism, and the hot stamping mechanism 2, the feeding mechanism 5, and the unloading mechanism 6 correspond to Installed on the periphery of the four-station turntable mechanism, and respectively cooperate with the corresponding stations on the four-station turntable mechanism in an orderly manner; the conveying platform 4 is correspondingly installed on the feeding level side of the cabinet 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com