Leather bronzing technique

A leather and process technology, applied in printing process, leather surface mechanical treatment, gold powder printing and other directions, can solve the problem of difficult gold powder coating hot stamping and other problems, achieve strong three-dimensional and glossy, and improve the effect of visual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

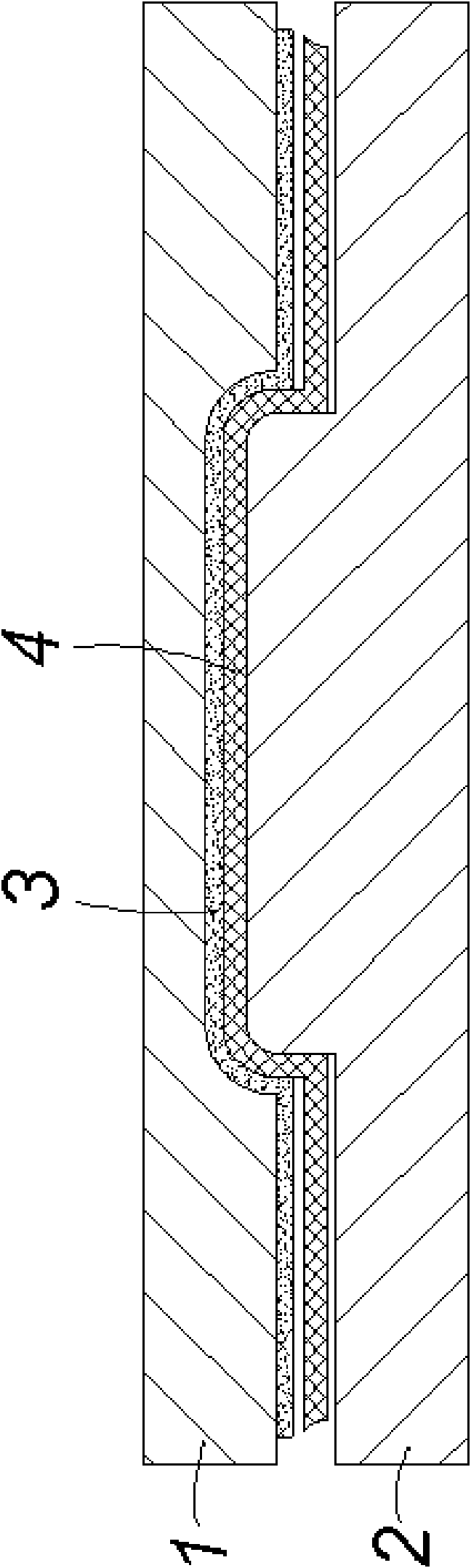

[0019] Fix the female intaglio 1 and the male relief 2 on the high temperature hot stamping die-cutting machine, place the 0.3mm thick PU leather on the male relief 2, cover the PU with a layer of tinfoil 3, and then put The female intaglio 1 and the male relief 2 are mold-closed. After mold-closing, the hot stamping temperature is kept at 60° C., and the pressure is kept at 2 tons, so that the gold powder paint on the tin foil paper 3 is hot stamped onto the embossed surface to form a gold powder coating. The bronzing pattern with this process has a strong sense of three-dimensionality and gloss. After repeated rubbing tests, the gold powder coating does not fade and has strong adhesion.

Embodiment 2

[0021] Fix the female intaglio 1 and the male relief 2 on the high temperature hot stamping die-cutting machine, place the leather with a thickness of 1.2mm on the male relief 2, cover the leather with a layer of tinfoil 3, and then place the female The intaglio plate 1 and the male mold relief plate 2 are mold-closed. After mold-closing, the hot stamping temperature is kept at 200° C. and the pressure is kept at 20 tons, so that the gold powder coating on the tinfoil paper 3 is hot stamped onto the embossed surface to form a gold powder coating. The bronzing pattern with this process has a strong sense of three-dimensionality and gloss. After repeated rubbing tests, the gold powder coating does not fade and has strong adhesion.

Embodiment 3

[0023] Fix the female intaglio 1 and the male relief 2 on the high temperature hot stamping die-cutting machine, place the PU leather with a thickness of 0.8mm on the male relief 2, cover the PU with a layer of tinfoil 3, and then place the The female intaglio 1 and the male relief 2 are mold-closed. After mold-closing, the hot stamping temperature is kept at 130° C., and the pressure is kept at 10 tons, so that the gold powder coating on the foil paper 3 is hot-stamped onto the embossed surface to form a gold powder coating. The bronzing pattern with this process has a strong sense of three-dimensionality and gloss. After repeated rubbing tests, the gold powder coating does not fade and has strong adhesion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com