Offset printing connecting line cold-foil printing process and equipment

A cold stamping and in-line technology, which is applied in the printing process, printing, printing machines, etc., can solve the problems of poor gloss of offset stamping products, limit the application range of offset cold stamping, high viscosity of cold stamping glue, etc., and achieve good surface smoothness, Excellent dot effect and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

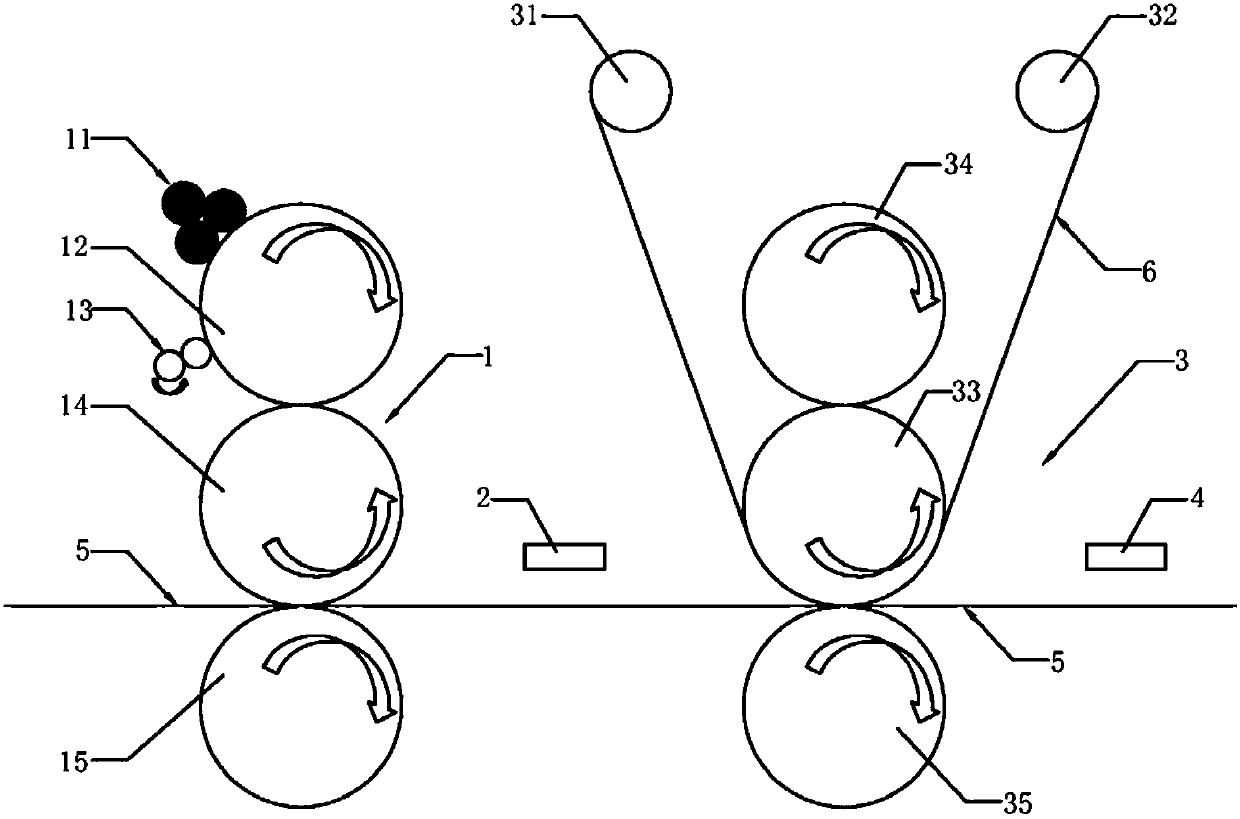

[0037] An offset printing in-line cold perm process, the following steps are performed on the offset printing in-line cold perm equipment:

[0038] A. Printing varnish: offset printing varnish on the surface of the printing substrate;

[0039] B. Curing for the first time: Curing the substrate printed with varnish in step A for the first time until the varnish is in a semi-cured state to obtain a printed matter with graphic varnish;

[0040] C. Pressing the cold stamping foil: press the cold stamping foil onto the surface of the printed matter obtained in step B, and then perform the second curing until it is fully cured to obtain a cold stamping product with pictures and texts.

[0041] In the step A, the amount of ink on the varnish is 0.8g / m 2 .

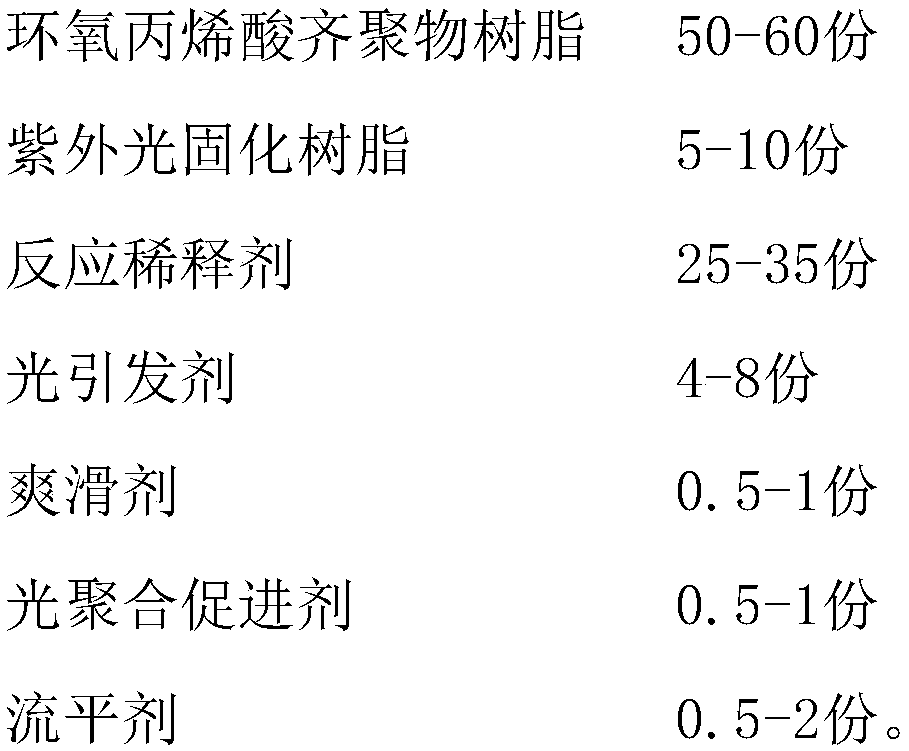

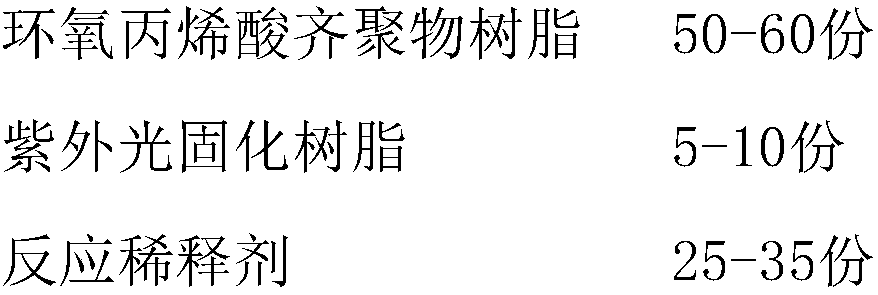

[0042] In the step A, the varnish is a low-viscosity ink fountain varnish, and the low-viscosity ink fountain varnish includes the following raw materials in parts by weight:

[0043]

[0044]

[0045] The ultraviolet cur...

Embodiment 2

[0053] An offset printing in-line cold perm process, the following steps are performed on the offset printing in-line cold perm equipment:

[0054] A. Printing varnish: offset printing varnish on the surface of the printing substrate;

[0055] B. Curing for the first time: Curing the substrate printed with varnish in step A for the first time until the varnish is in a semi-cured state to obtain a printed matter with graphic varnish;

[0056] C. Pressing the cold stamping foil: press the cold stamping foil onto the surface of the printed matter obtained in step B, and then perform the second curing until it is fully cured to obtain a cold stamping product with pictures and texts.

[0057] In the step A, the amount of ink on the varnish is 1.8g / m 2 .

[0058] In the step A, the varnish is a low-viscosity ink fountain varnish, and the low-viscosity ink fountain varnish includes the following raw materials in parts by weight:

[0059]

[0060] The ultraviolet curable resin i...

Embodiment 3

[0068] An offset printing in-line cold perm process, the following steps are performed on the offset printing in-line cold perm equipment:

[0069] A. Printing varnish: offset printing varnish on the surface of the printing substrate;

[0070] B. Curing for the first time: Curing the substrate printed with varnish in step A for the first time until the varnish is in a semi-cured state to obtain a printed matter with graphic varnish;

[0071] C. Pressing the cold stamping foil: press the cold stamping foil onto the surface of the printed matter obtained in step B, and then perform the second curing until it is fully cured to obtain a cold stamping product with pictures and texts.

[0072] In the step A, the amount of ink on the varnish is 2.9g / m 2 .

[0073]In the step A, the varnish is a low-viscosity ink fountain varnish, and the low-viscosity ink fountain varnish includes the following raw materials in parts by weight:

[0074]

[0075] The ultraviolet curable resin is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com