Production process of large-jacquard home-textile fabric interweaved by using double-color low-elasticity polyester filaments and coarse cotton

A production process and technology of polyester yarn, which is applied in the processing of textile materials, liquid/gas/vapor textile material processing, spinning, etc., to achieve the effect of expanding industrial scale, good wear resistance, and good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

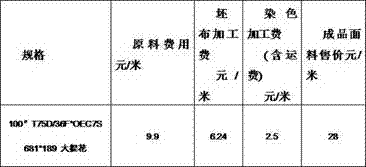

[0014] The production process of a jacquard home textile fabric interwoven with two-color low-elastic polyester yarn and coarse-count cotton in this embodiment includes (1) raw materials: the warp yarn adopts T 75D / 36F low-elastic heavy net semi-dull filament, and the weft yarn selects 83.3tex / OEC7S air-spun cotton yarn; the warp density is 681 threads / 10cm; the weft yarn is 83.3tex air-spun cotton yarn, the weft density is 189 threads / 10cm, and the width is 254cm;

[0015] (2) Weaving process:

[0016] A: Sectional warping process: the number of warping roots is 304*56+112*1; 478*43+454*1; the width*number of bars is 47.19*56+17.39*1; the displacement is 0.74 (cm The warping process must do the following: ① do a good job in the maintenance of the equipment to ensure that the equipment is in good condition; ② do a good job of cleaning to ensure that the yarn channel is smooth and clean without burrs, and the yarn is unwound without obstruction. The tension is uniform; ③The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com