Inorganic nanometer silica modified PBT nanometer composite spinning material, and preparation method thereof

An inorganic nano-silicon and nano-composite technology, which is applied in the manufacture of rayon, textiles and paper, single-component polyester rayon, etc., can solve the problems of PBT industrial application impact, sensitivity to warping gaps, etc., and achieve product The effect of high added value and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] According to the present invention, the preparation method of the described modified inorganic nano-silica comprises:

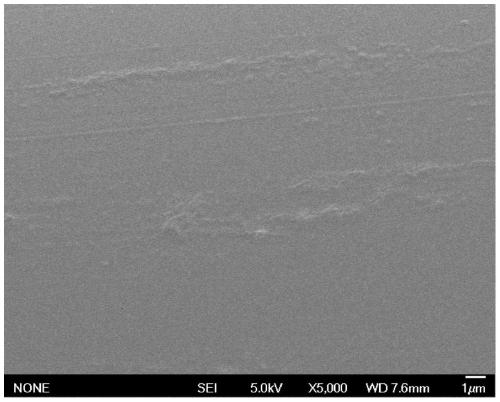

[0029] Mix and grind sheet-shaped potassium aluminum silicate, dispersant, surfactant and deionized water to obtain modified inorganic nano-silica; the thickness of the sheet-shaped potassium aluminum silicate is less than or equal to 200nm, and the value of the diameter-thickness ratio is The range is 10-20. When the aspect ratio is greater than 20, the spinnability of the nanocomposite brush filament will be affected; when the aspect ratio is less than 10, the microstructure of the nanocomposite brush filament surface does not change significantly, and the expected powder sticking effect cannot be achieved. The mass percent of the sheet-like potassium aluminum silicate, dispersant, silane coupling agent and deionized water is preferably 50:10:2:38.

[0030] According to the present invention, the grinding can be done by means commonly used in this f...

Embodiment 1

[0037] After dedusting and impurity removal of sheet-shaped potassium aluminum silicate (diameter-thickness ratio: 10, thickness: 200nm), take 50 parts of sheet-shaped potassium aluminum silicate, 10 parts of dispersant BYK163, 2 parts of silane coupling agent KH560, deionized water 38 parts were subjected to high-speed wet grinding for 10 hours, and spray-dried to obtain modified inorganic nano-silica;

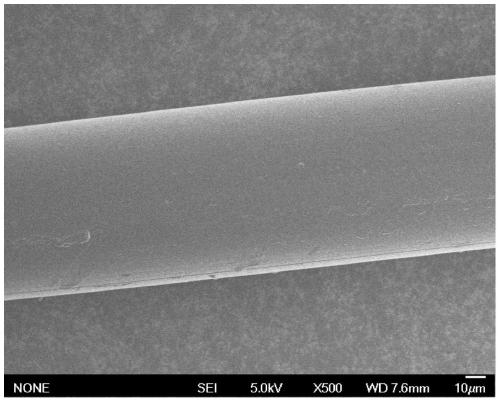

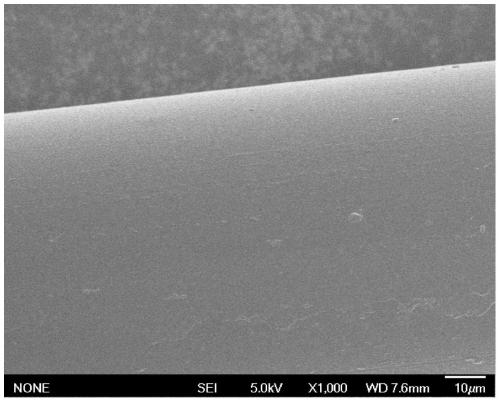

[0038] Drying the PBT material and the modified inorganic nano-silica, the drying temperature is 125°C, and the drying time is 4h, which can improve the spinnability of the fiber; the PBT material: 97.4 parts by weight, the modified inorganic nano-silica : 0.1 part, Antioxidant 1010: 1.0 part, Lubricant 3853: 1.5 part Stir and mix until uniform, adopt melt blending method, make the mixture extrude and granulate through twin-screw extruder; extrusion temperature is 270°C , and then dry the pellets in a vacuum oven at 125°C; then extrude and spin the pellets; the highest spinni...

Embodiment 2

[0040] After dedusting and impurity removal of sheet-shaped potassium aluminum silicate (diameter-thickness ratio: 10, thickness: 200nm), take 50 parts of sheet-shaped potassium aluminum silicate, 10 parts of dispersant BYK163, 2 parts of silane coupling agent KH560, deionized water 38 parts were subjected to high-speed wet grinding for 10 hours, and spray-dried to obtain modified inorganic nano-silica;

[0041] Dry the PBT material and the modified inorganic nano-silica, the drying temperature is 125 ° C, and the drying time is 4 hours, which can improve the spinnability of the fiber; the PBT material: 97.3 parts by weight, the modified inorganic nano-silica : 0.2 parts, Antioxidant 1010: 1.0 parts, Lubricant 3853: 1.5 parts Stir and mix until uniform, adopt melt blending method, make the mixture extrude and granulate through twin-screw extruder; extrusion temperature is 270°C , and then dry the pellets in a vacuum oven at 125°C; then extrude and spin the pellets; the highest...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com