Denim fabric preparation method

A denim fabric, fabric technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

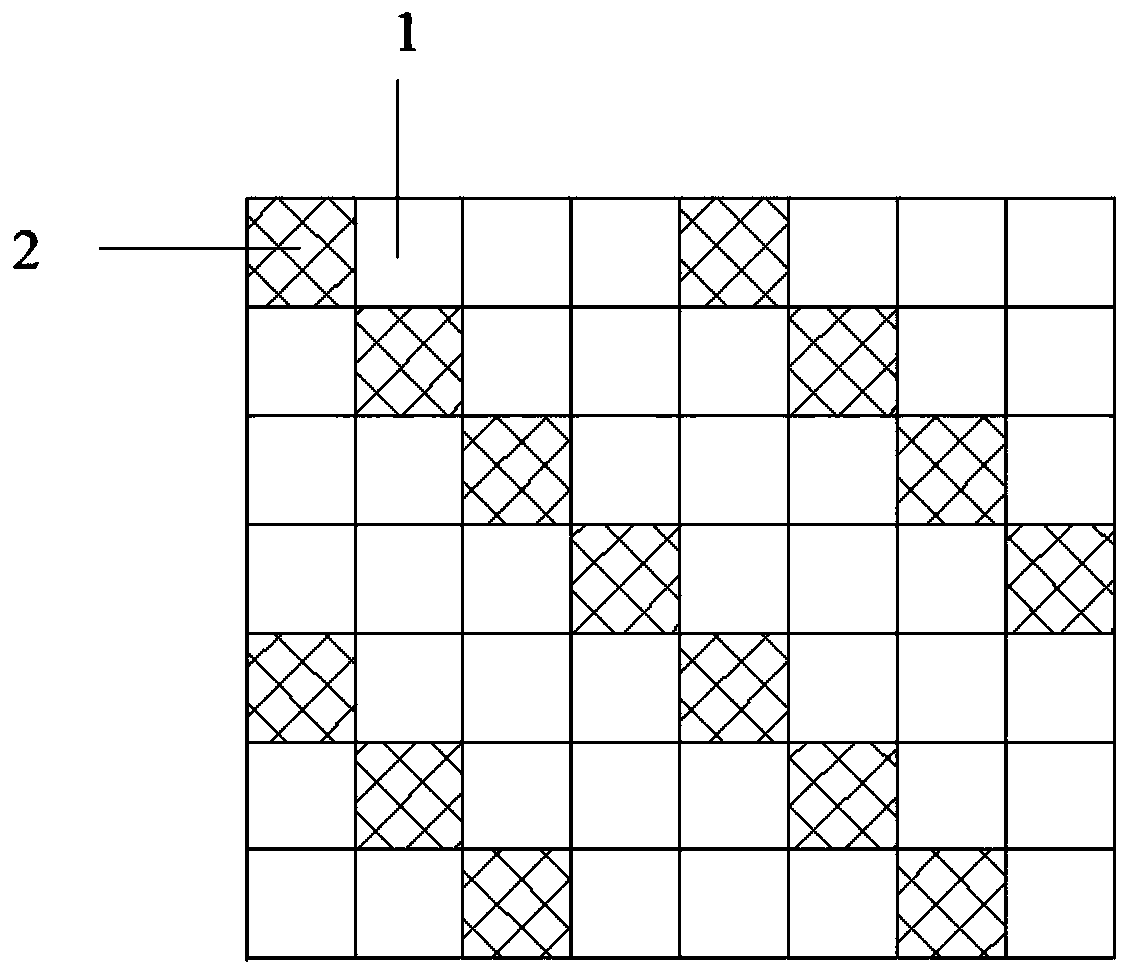

Image

Examples

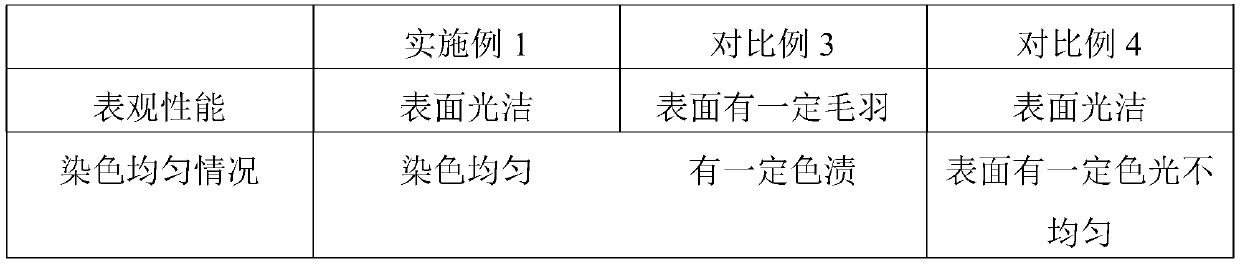

Embodiment 1

[0021] A preparation method of denim fabric, after twisting the warp and weft yarns, dyeing the warp yarns with indigo, and finally weaving the weft yarns and the dyed warp yarns to satin to obtain fabrics, and then sequentially desizing, washing, softening, and shaping, and the final product Inspect and roll the package. During the desizing process, the remaining color stains and impurities in the fibers can be removed; the finishing process is as follows: the washed and dried fabrics are placed in a softening solution to make the fabrics , the waterproof, antistatic and hand feeling have been significantly improved; during the setting process, the fabric is dried in an open width and then checked to ensure that there is no problem with the fabric surface, and the fabric can be set by a high-temperature setting machine according to the user's requirements.

[0022] Among them, the warp yarn is twisted from staple fiber and wool, and the twist range of the staple fiber is 250-3...

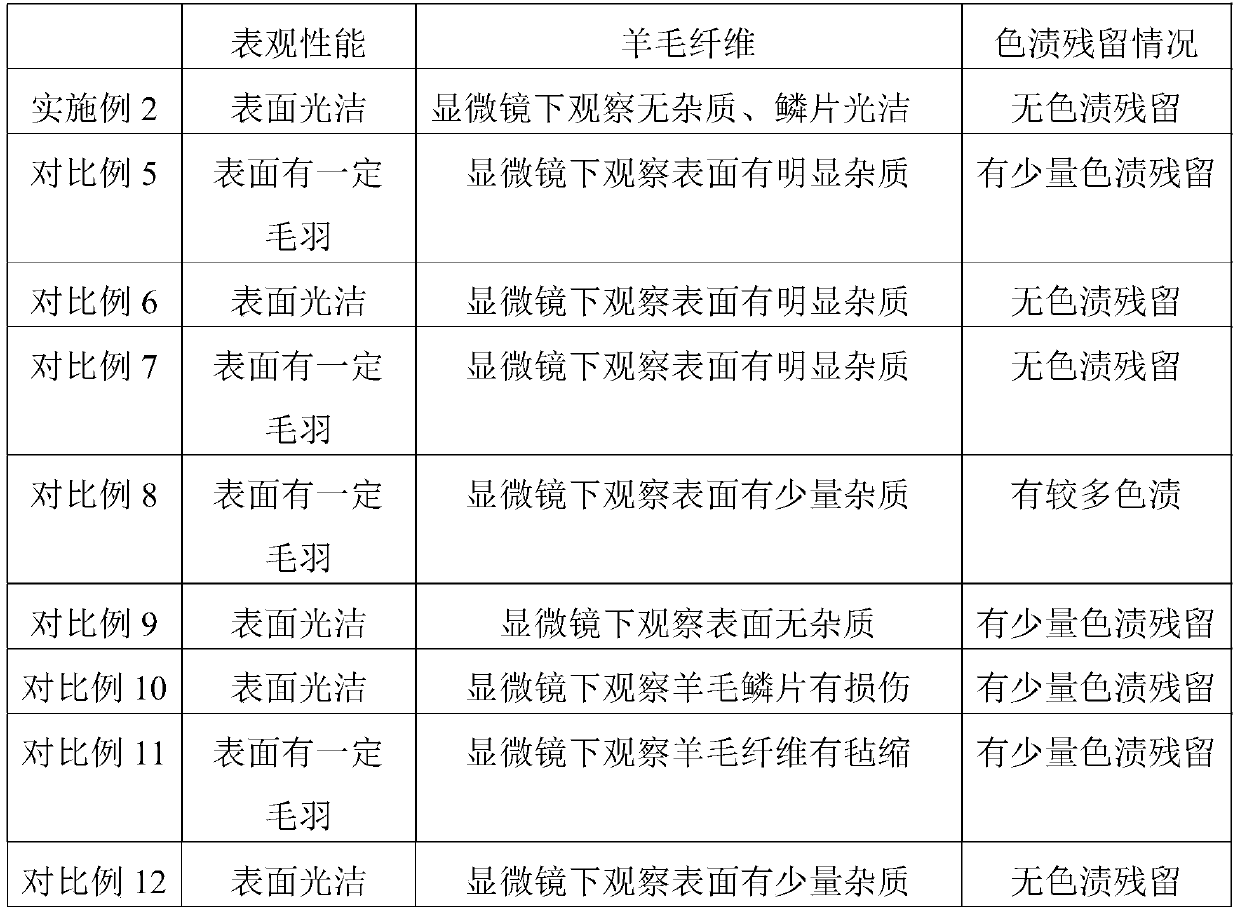

Embodiment 2

[0038] Compared with Example 1, most of them are the same, except that it is further defined in this example:

[0039] Before twisting, the wool is scoured first. The scouring process is as follows: soap is used as detergent, sodium carbonate is used as builder, the pH value is controlled at 8-9, the temperature is 40-55°C, and the scouring time is 10°C. ~20min. The mass dosage of the soap is 2% to 4% of the mass of the raw wool to be treated, and the mass dosage of the sodium carbonate is 2% of the mass of the raw wool to be treated.

Embodiment 3

[0060] Compared with embodiment 1 or 2, most of them are all the same, except further defining in this embodiment:

[0061] The indigo dyeing process is specifically: weigh the warp yarn and the indigo dye according to the mass ratio of warp yarn: indigo dye=1:(1.8~2.2), soak the warp yarn in the indigo dye for dyeing, take out the soaked warp yarn and carry out air-drying, after air-drying Promptly obtain the finished warp yarn of dyeing. Wherein, the indigo dye is an acid dye, which is formed by mixing natural indigo and plastocyanin in a weight ratio of 1:(0.65-0.85), preferably, the weight ratio of natural indigo and plastocyanin is 1:0.75. The soaking temperature is 35-45°C, the soaking time is 1.5-2.5h, the air-drying temperature is 80-85°C, and the air-drying time is 30-50min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com