Toothbrush-shaped printing method

A printing method and toothbrush technology, applied in the field of fabric printing, can solve the problems of disorderly flocking, complex process, easy shedding of flocked fabrics, etc., and achieve the effects of rich pattern changes, strong three-dimensional effect, and colorful colors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

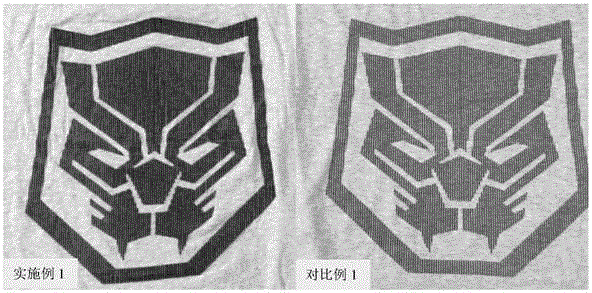

Embodiment 1

[0027] First, paste the photosensitive adhesive layer on the screen frame with water, alcohol or photosensitive adhesive. After drying with hot air, remove the base of the photosensitive film, and then print the plate. The machine installs the prepared screen, and prints on the machine;

[0028] The pattern thickness is printed with thermosetting right-angle ink, and the number of printing is controlled at 20 times. After each printing, it is placed in an oven for drying. The drying temperature is 145 °C, the drying time is 45 seconds, and the pressure of the printing machine is 1MPa. Every 5 times of printing, the pressure is reduced by 0.2MPa for printing;

[0029] The pattern is three-dimensionally printed with thermosetting fillet ink. The number of printings is controlled at 3 times. After each printing, it is placed in an oven for drying. The drying temperature is 145 °C, the drying time is 45 seconds, and the pressure of the printing machine is 1MPa. Printing is perfor...

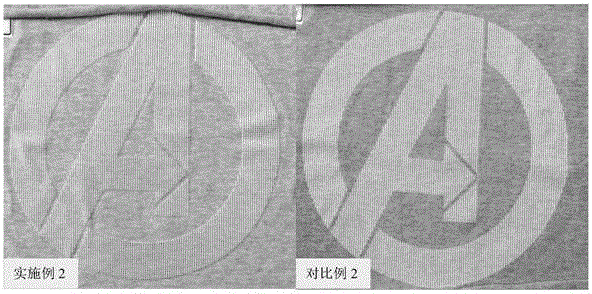

Embodiment 2

[0035] First paste the photosensitive adhesive layer on the screen frame with water, alcohol or photosensitive adhesive, after drying with hot air, remove the base of the photosensitive film, and then print the plate, and use a flat screen or rotary screen printing machine to install the prepared screen plate. OK, print on the machine;

[0036] The pattern thickness is printed with thermosetting right-angle ink, and the number of printing is controlled at 25 times. After each printing, it is placed in an oven for drying. The drying temperature is 160 °C, the drying time is 80 seconds, and the pressure of the printing machine is 1MPa. Every 5 times of printing, the pressure is reduced by 0.2MPa for printing;

[0037] The pattern is three-dimensionally printed with thermosetting fillet ink, and the number of printing is controlled at 8 times. After each printing, it is placed in an oven for drying. The drying temperature is 160 ° C, the drying time is 80 seconds, and the pressur...

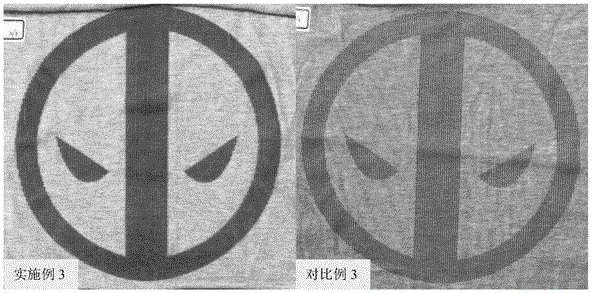

Embodiment 3

[0043] First paste the photosensitive adhesive layer on the screen frame with water, alcohol or photosensitive adhesive, after drying with hot air, remove the base of the photosensitive film, and then print the plate, and use a flat screen or rotary screen printing machine to install the prepared screen plate. OK, print on the machine;

[0044] The pattern thickness is printed with thermosetting right-angle ink, and the number of printings is controlled at 22 times. After each printing, it is placed in an oven for drying. Every 5 times of printing, the pressure is reduced by 0.2MPa for printing;

[0045] The pattern is three-dimensionally printed with thermosetting fillet ink. The number of printings is controlled at 5 times. After each printing, it is placed in an oven for drying. The drying temperature is 150 °C, the drying time is 60 seconds, and the pressure of the printing machine is 1MPa. Printing is performed at a pressure that decreases by 0.2 MPa every 3 times.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com