Cellphone battery holder with high tinning fullness degree

A cell phone battery, fullness technology, applied in battery circuit devices, current collectors, electronic equipment and other directions, can solve the problems of poor heat dissipation, insufficient tin fullness, shortened battery life, etc., to achieve good adsorption positioning effect, The effect of good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

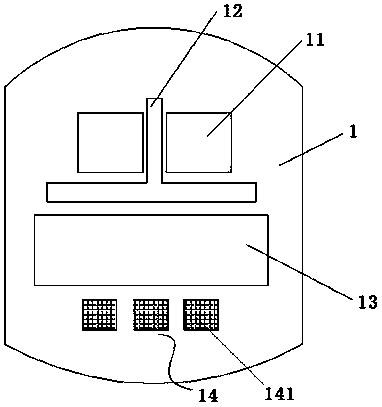

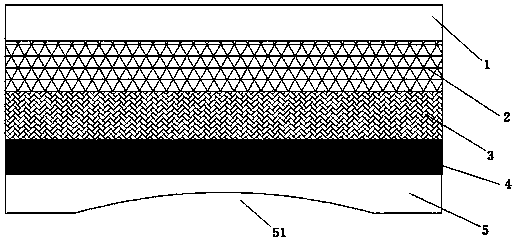

[0018] The mobile phone battery holder with high tin fullness is characterized in that it includes a panel 1, the panel is provided with a power supply area 11, a baffle 12, a charging area 13, and a tin point area 14, and the power supply area is arranged between the baffles Between, the charging area is set under the baffle, the tin point area is set under the charging area, the power supply area, charging area, and tin point area are electrically connected; A fiber layer 2 , a second fiber layer 3 , a metal layer 4 , and a silica gel layer 5 .

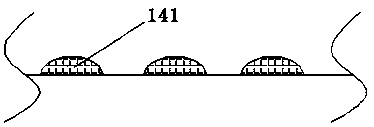

[0019] Further, the tin dot area includes tin dots 141 arranged symmetrically, the tin dots are arranged in an arc shape, and the height of the tin dots is 0.06 mm.

[0020] Further, the first fiber layer is a plant fiber layer.

[0021] Further, the plant fiber layer is a flax fiber layer.

[0022] Further, the second fiber layer is a regenerated fiber layer.

[0023] Further, the regenerated fiber layer is an acetate fiber laye...

Embodiment 2

[0028] The mobile phone battery holder with high tin fullness is characterized in that it includes a panel, and the panel is provided with a power supply area, a baffle, a charging area, and a tin spot area, the power supply area is set between the baffles, and the charging The area is set under the baffle, the tin point area is set under the charging area, and the power supply area, charging area, and tin point area are electrically connected; the first fiber layer, the second Two fiber layer, metal layer, silicone layer.

[0029] Further, the tin dot area includes tin dots arranged symmetrically, the tin dots are arranged in an arc, and the height of the tin dots is 0.03 mm.

[0030] Further, the first fiber layer is a plant fiber layer.

[0031] Further, the plant fiber layer is a flax fiber layer.

[0032] Further, the second fiber layer is a regenerated fiber layer.

[0033] Further, the regenerated fiber layer is a combination of viscose fiber layer and acetate fiber ...

Embodiment 3

[0038] The mobile phone battery holder with high tin fullness is characterized in that it includes a panel, and the panel is provided with a power supply area, a baffle, a charging area, and a tin spot area, the power supply area is set between the baffles, and the charging The area is set under the baffle, the tin point area is set under the charging area, and the power supply area, charging area, and tin point area are electrically connected; the first fiber layer, the second Two fiber layer, metal layer, silicone layer.

[0039] Further, the tin dot area includes tin dots arranged symmetrically, the tin dots are arranged in an arc, and the height of the tin dots is 0.08 mm.

[0040] Further, the first fiber layer is a plant fiber layer.

[0041] Further, the plant fiber layer is a flax fiber layer.

[0042] Further, the second fiber layer is a regenerated fiber layer.

[0043] Further, the regenerated fiber layer is a viscose fiber layer.

[0044] Further, the bottom of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com