HAA solidified polyester resin for sand streak powder coating and preparation method thereof

A technology of powder coating and polyester resin, which is applied in the field of polyester resin, can solve the problems of insufficient unevenness of texture, insufficient mechanical properties, and high gloss of sand grains, and achieve strong unevenness, excellent mechanical properties, and low surface gloss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

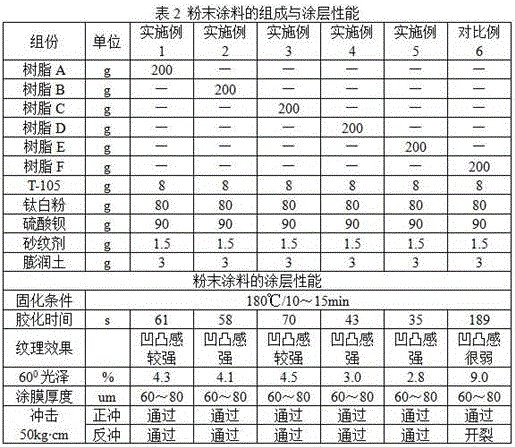

[0025] Some specific examples are enumerated below to illustrate the present invention, and Table 1 shows the examples and comparative examples of polyester resins. In the reactor, add neopentyl glycol, methylpropanediol, 1,4-cyclohexanedimethanol, trimethylolpropane, and trimethylolethane in proportions listed in Table 1, and heat up to the Melt; then add terephthalic acid, monobutyl dihydroxy tin chloride, continue to heat up the reaction with nitrogen, until 180 ° C esterification water begins to form and distill; then gradually increase the temperature to 245 ° C, and react for 9 to 13 hours to More than 95% of the esterification water is discharged. At this time, the material system is clear and transparent, and the acid value reaches 18-23mgKOH / g; the temperature is lowered to 230°C, and the acidolysis agent is added in a proportioned amount, and the reaction is 2-4 hours. At this time, the material system is clear Transparent, the acid value reaches 32-38 mgKOH / g; after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com