360-degree embossment whole-body anti-skid stainless steel chopstick processing process

A technology for processing chopsticks and stainless steel, applied in the field of processing technology of stainless steel chopsticks, can solve the problems of slip resistance and poor hygiene, and achieve the effects of maintaining gloss, good handling in hand, and good anti-slip property for picking vegetables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

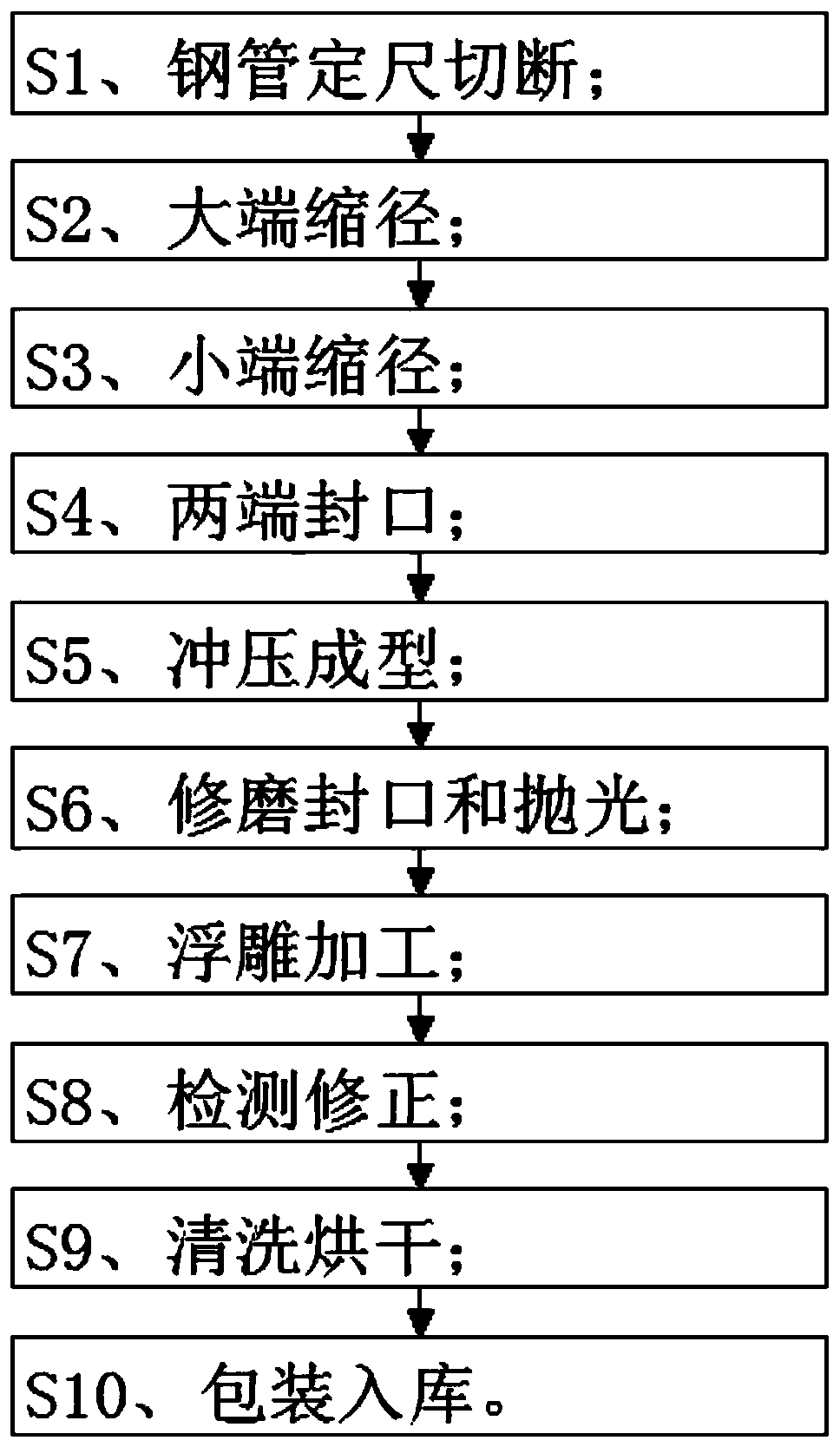

[0032] 1. A 360-degree embossed anti-slip stainless steel chopsticks processing technology is characterized in that, comprising the following steps:

[0033] S1. Steel pipe cutting to length: according to the length of the chopsticks to be made, pass a stainless steel pipe with a diameter of 8mm and a pipe wall thickness of 1.4mm through the main shaft of the cutting device. Tighten the steel pipe, the main shaft drives the blade installed on it to rotate, and at the same time, the two cutter heads suspended on the head of the main shaft move radially to cut the steel pipe to make a stainless steel pipe section. The cutting device uses a high-speed steel round blade to cut, and the cutting motor The power is 0.75kW;

[0034] S2. Large-end diameter reduction: Use a necking machine to reduce the diameter of one end of the stainless steel pipe section. The length of the diameter reduction part is 5mm, and the number of diameter reductions is 3 times. The end size is reduced to a ...

Embodiment 2

[0044] 1. A 360-degree embossed anti-slip stainless steel chopsticks processing technology is characterized in that, comprising the following steps:

[0045] S1. Steel pipe cutting to length: according to the length of the chopsticks to be made, pass a stainless steel pipe with a diameter of 6mm and a pipe wall thickness of 1.2mm through the main shaft of the cutting device. Tighten the steel pipe, the main shaft drives the blade installed on it to rotate, and at the same time, the two cutter heads suspended on the head of the main shaft move radially to cut the steel pipe to make a stainless steel pipe section. The cutting device uses a high-speed steel round blade to cut, and the cutting motor The power is 0.75kW;

[0046] S2. Large-end diameter reduction: Use a necking machine to reduce the diameter of one end of the stainless steel pipe section. The length of the diameter reduction part is 3mm, and the number of diameter reductions is 2 times. The end size is reduced to a ...

Embodiment 3

[0056] 1. A 360-degree embossed anti-slip stainless steel chopsticks processing technology is characterized in that, comprising the following steps:

[0057] S1. Steel pipe cutting to length: according to the length of the chopsticks to be made, pass a stainless steel pipe with a diameter of 7mm and a pipe wall thickness of 1.3mm through the main shaft of the cutting device. Tighten the steel pipe, the main shaft drives the blade installed on it to rotate, and at the same time, the two cutter heads suspended on the head of the main shaft move radially to cut the steel pipe to make a stainless steel pipe section. The cutting device uses a high-speed steel round blade to cut, and the cutting motor The power is 0.75kW;

[0058] S2. Large-end diameter reduction: Use a necking machine to reduce the diameter of one end of the stainless steel pipe section. The length of the diameter reduction part is 4mm, and the number of diameter reductions is 2 times. The size of the end is reduce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com