Novel vacuum sieved sand-in-water multicolor paint and preparation method thereof

A multi-color coating and vacuum technology, applied in the coating field, can solve the problems of color particles being easily affected by shear force, poor formula stability, and insufficient color, and achieve the effect of bright colors, improved stability, and strong concave-convex feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A novel vacuum-sieved sand-in-water multi-color coating of the present invention, said novel vacuum-sieved sand-in-water multi-color coating comprises the following components by mass percentage:

[0045] Disperse Phase Tinted Base Paint 50%,

[0046] Continuous phase varnish 30%,

[0047] Protective gel solution 20%.

[0048] Described disperse-phase toning base paint is made up of white base paint and colored quartz sand,

[0049] Described dispersed phase toning base paint comprises the following components by mass percentage:

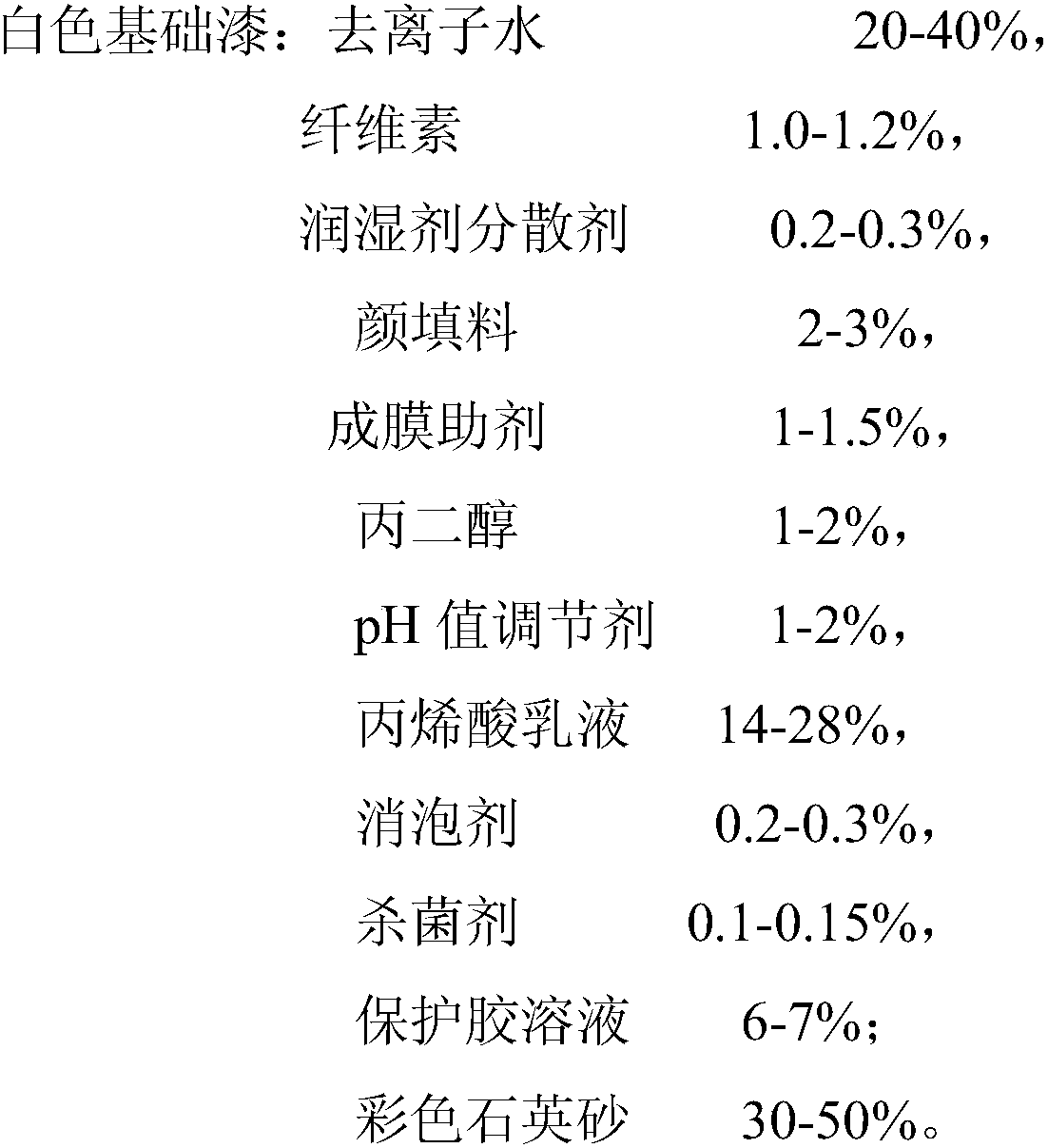

[0050] Said white base paint:

[0051]

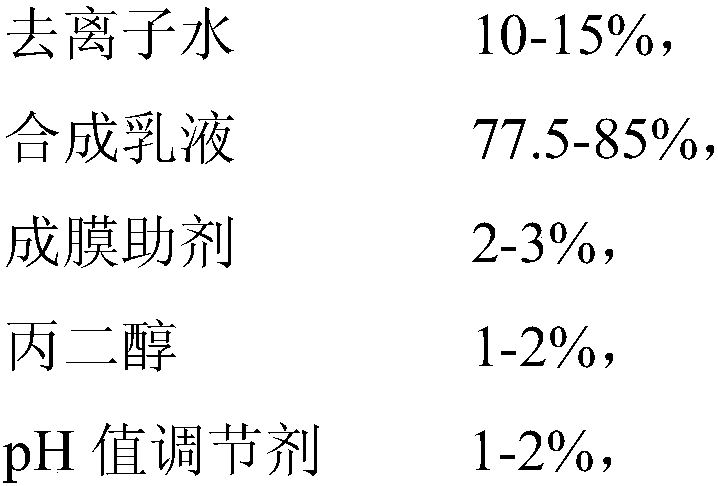

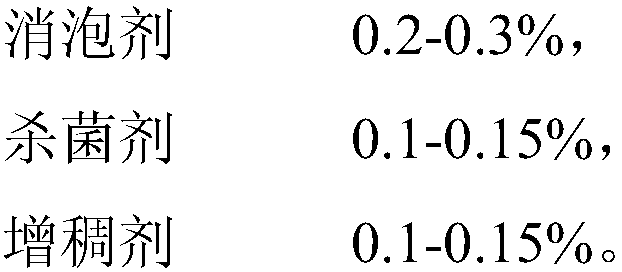

[0052] Described continuous phase varnish is made up of following components by mass percentage:

[0053]

[0054] Described protective colloid solution is by mass percent:

[0055] Protective rubber powder 6.5%,

[0056] Deionized water 93.5%.

[0057] The cellulose is hydroxyethyl cellulose; the wetting agent dispersant is polyacrylic acid ammonium salt dispersant; the pigment and filler...

Embodiment 2

[0074] The difference between embodiment 2 and embodiment 1 is:

[0075] A novel vacuum-sieved sand-in-water multi-color coating of the present invention, said novel vacuum-sieved sand-in-water multi-color coating comprises the following components by mass percentage:

[0076] Disperse Phase Tinted Base Paint 40%,

[0077] Continuous phase varnish 30%,

[0078] Protective gel solution 30%.

[0079] Described disperse-phase toning base paint is made up of white base paint and colored quartz sand,

[0080] Described dispersed phase toning base paint comprises the following components by mass percentage:

[0081] Said white base paint:

[0082]

[0083]

[0084] Described continuous phase varnish is made up of following components by mass percentage:

[0085]

[0086] Described protective colloid solution is by mass percent:

[0087] Protective rubber powder 6%,

[0088] Deionized water 94%.

[0089] The pigments and fillers are a combination of rutile titanium d...

Embodiment 3

[0105] The difference between embodiment 3 and embodiment 1 is:

[0106] A novel vacuum-sieved sand-in-water multi-color coating of the present invention, said novel vacuum-sieved sand-in-water multi-color coating comprises the following components by mass percentage:

[0107] Disperse Phase Tinted Base Paint 45%,

[0108] Continuous phase varnish 35%,

[0109] Protective gel solution 20%.

[0110] Described disperse-phase toning base paint is made up of white base paint and colored quartz sand, and described disperse-phase toning base paint comprises the following components by mass percentage:

[0111] Said white base paint:

[0112]

[0113] Described continuous phase varnish is made up of following components by mass percentage:

[0114]

[0115] Described protective colloid solution is by mass percent:

[0116] Protective rubber powder 7%,

[0117] Deionized water 93%.

[0118] The cellulose is hydroxyethyl cellulose; the wetting agent dispersant is polyacryl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com